Compact liquid film thickness and temperature synchronous measurement system

A technology for simultaneous measurement of liquid film thickness, applied in thermometers, measuring heat, measuring devices, etc., can solve the problems of large influence, many optical components, large space occupation, etc., to achieve simple and compact structure, accurate measurement results, and reduced size The effect of light intensity attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects realized by the present invention easy to understand, the following embodiments will specifically describe the compact liquid film thickness and temperature synchronous measurement system of the present invention in conjunction with the accompanying drawings.

[0025]

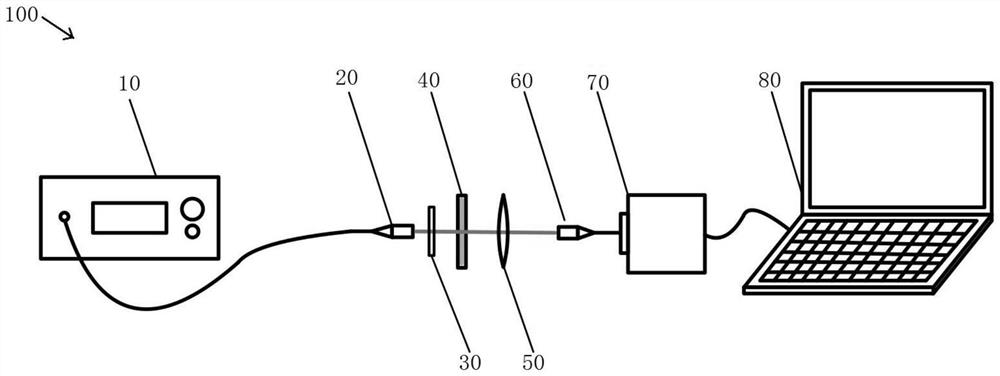

[0026] figure 1 It is a schematic structural diagram of a compact liquid film thickness and temperature synchronous measurement system in an embodiment of the present invention.

[0027] like figure 1 As shown, the compact liquid film thickness and temperature synchronous measurement system 100 includes a halogen light source 10, a fiber collimator 20, a filter 30, a cuvette 40, a convex lens 50, a fiber probe 60, a spectrometer 70, a computer 80, and a water bath heating device (not shown in the figure).

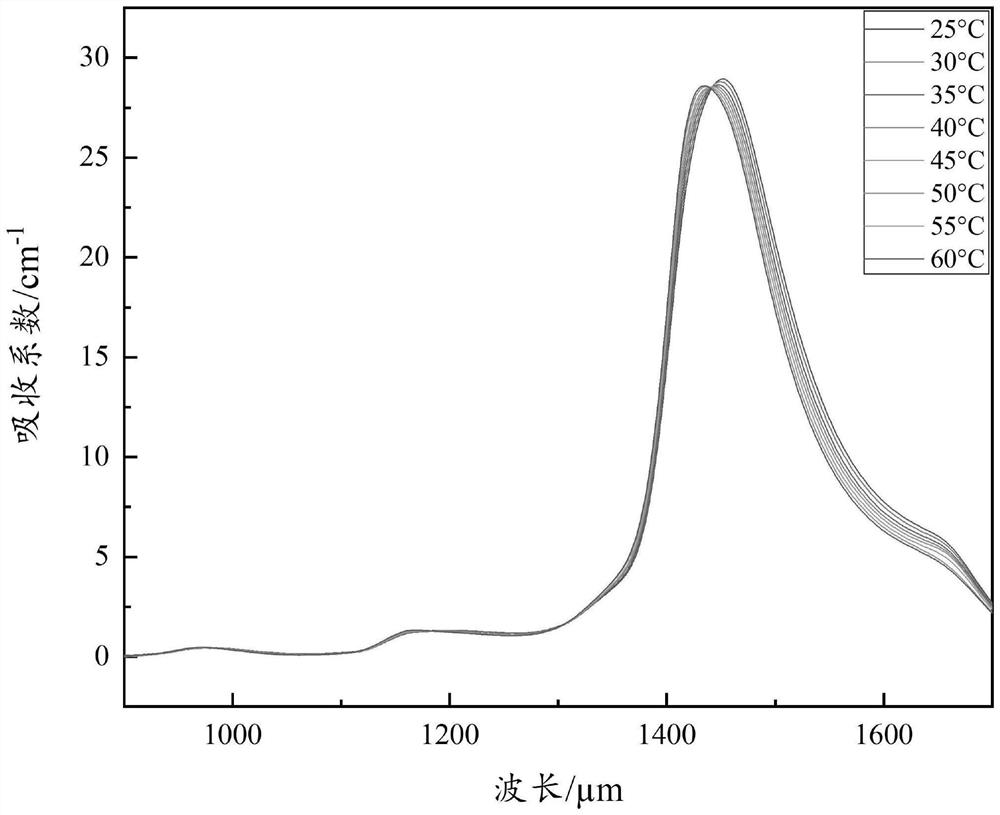

[0028] In this embodiment, the liquid medium to be tested is deionized water.

[0029] The halogen light source 10 is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com