Lithium ion battery negative electrode material and preparation method thereof

A technology for lithium-ion batteries and negative electrode materials, which is applied in battery electrodes, secondary batteries, and nanotechnology for materials and surface science. In order to achieve the effect of maintaining phase stability and dimensional advantages, increasing conductivity, and inhibiting agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A first aspect of the present invention discloses a method for preparing a negative electrode material for a lithium ion battery. The main steps are as follows:

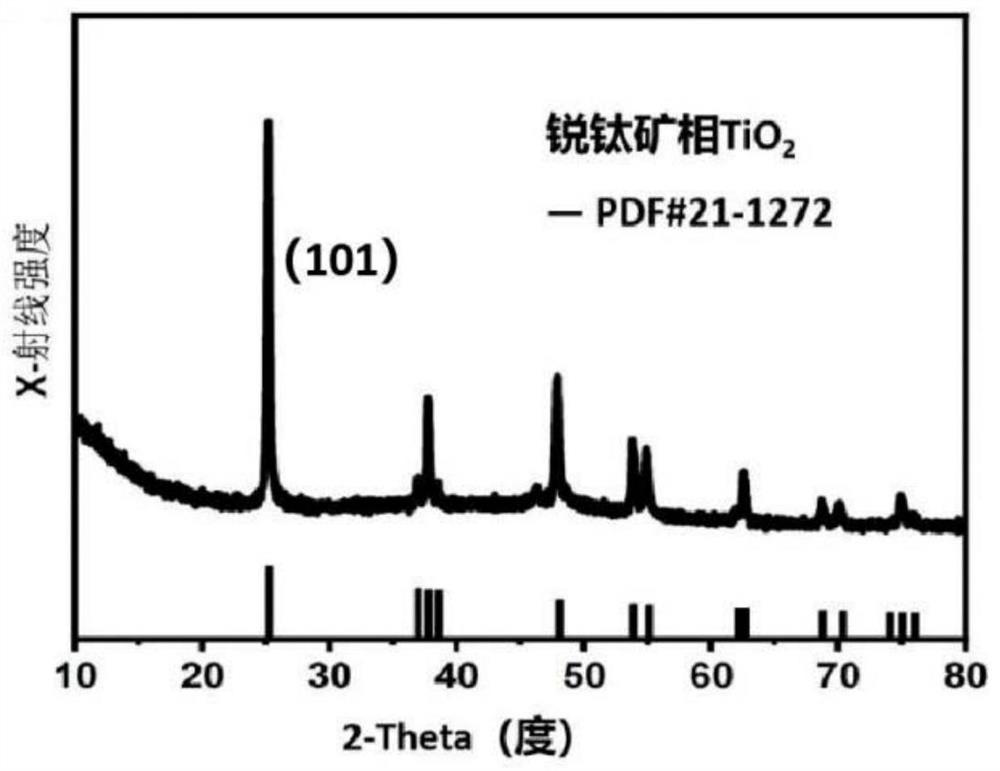

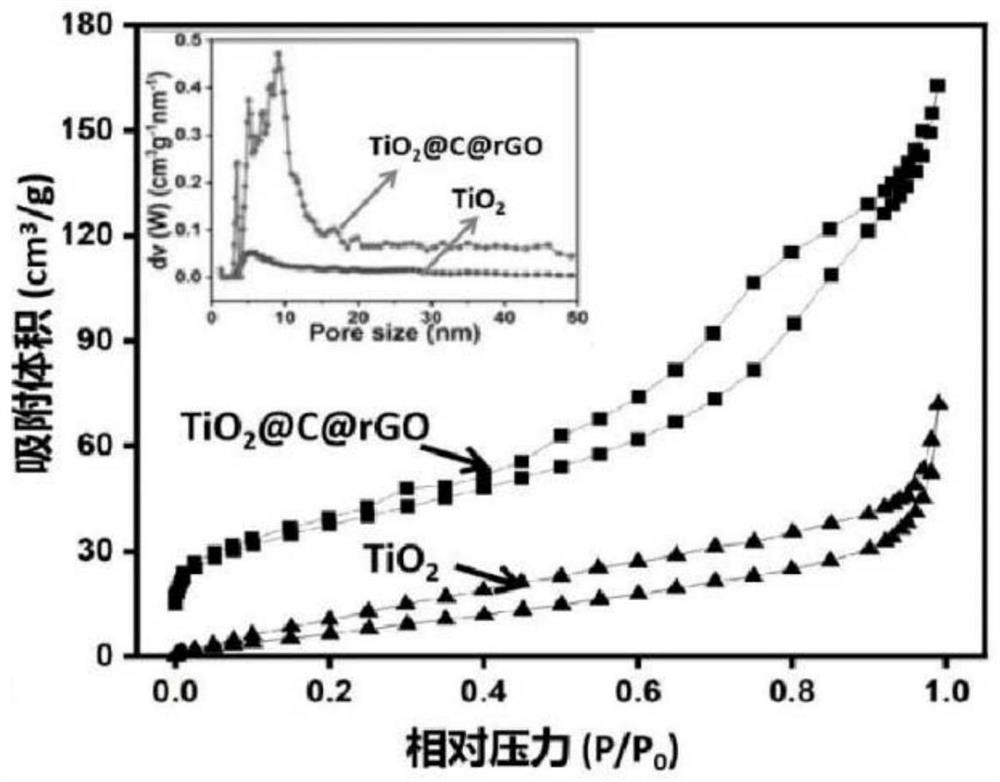

[0036] Preparation of anatase octahedral TiO 2

[0037] Octahedral TiO 2 Compared with ordinary titanium dioxide or titanium dioxide arrays, its structure is more stable, and as a battery material, it can increase the number of charge-discharge cycles of the material, and the capacity attenuation is small; and its specific surface area is large, which can provide more space for ion reactions and area. Octahedral TiO in this paper 2 It can be obtained by a conventional preparation process in the field, and there is no special limitation. In some specific embodiments of the present invention, the specific preparation method is as follows: first, the titanium source and benzoic acid are respectively added into acetonitrile and mixed uniformly to form a solution. a and solution b; adding the solution a into ...

Embodiment 1

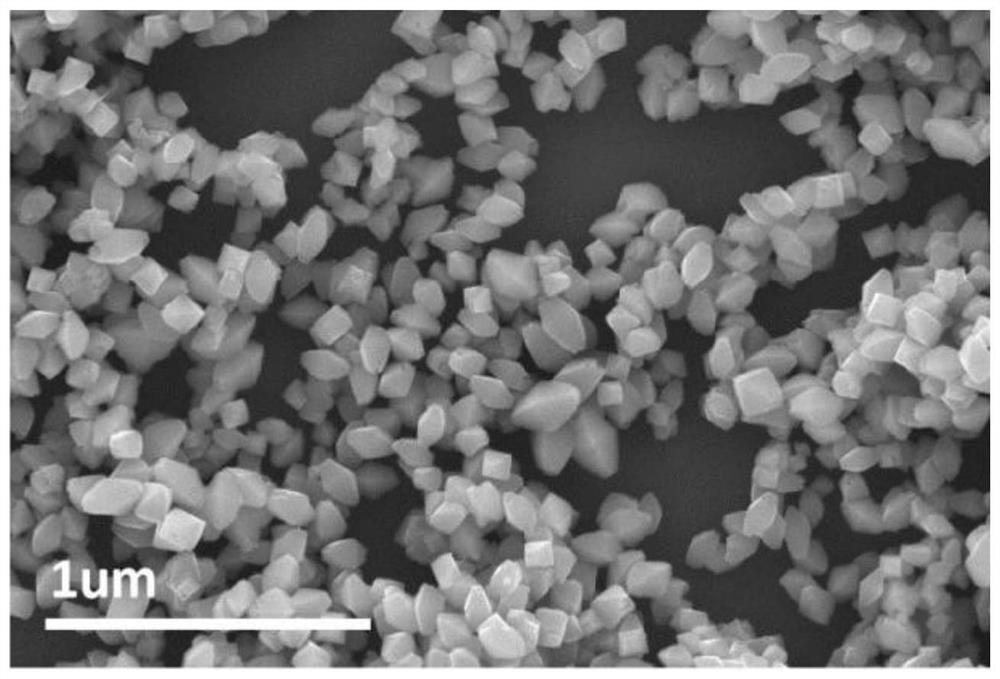

[0048] Preparation of octahedral TiO 2

[0049] Mix 0.625mL of titanium tetraisopropoxide with 4.08mL of acetonitrile and stir evenly, marked as solution a; add 2.268g of benzoic acid to 20.36mL of acetonitrile and stir evenly, marked as solution b; mix solution a and solution b, stir After about 30 minutes, the mixed solution was transferred to the reaction kettle and kept at 100°C for 15 hours; when the reaction stopped and cooled to room temperature, washed several times with acetonitrile and dried at room temperature to obtain the titanium dioxide precursor;

[0050] Weigh 0.061 g of titanium dioxide precursor, add 2 mL of DMF, and stir for tens of minutes. After waiting for the solution to be uniform, add 2.25 mL of NaF with a concentration of 0.8 mol / L and 5.75 mL of ultrapure water to it. After stirring evenly, transfer the mixture. In the reaction kettle, after reacting at 180 °C for 24 h, cooled to room temperature, the white precipitate was collected by centrifuga...

Embodiment 2

[0060] Preparation of octahedral TiO 2

[0061] Mix 0.625mL of titanium tetraisopropoxide with 4.08mL of acetonitrile and stir evenly, marked as solution a; add 2.268g of benzoic acid to 20.36mL of acetonitrile and mix and stir evenly, marked as solution b; mix solutions a and b, After stirring for about 30min, the mixed solution was transferred to the reaction kettle and kept at 100°C for 15h; when the reaction stopped naturally cooled to room temperature, washed several times with acetonitrile, and dried at room temperature to obtain the titanium dioxide precursor;

[0062] Weigh 0.061 g of titanium dioxide precursor, add it to 2 mL of DMF and stir for tens of minutes, wait for the solution to be uniform, add 1 mL of NaF with a concentration of 0.8 mol / L and 7 mL of ultrapure water to it, stir evenly, and then transfer the mixture to a In the reaction kettle, react at 180°C for 20 hours. After cooling to room temperature, the white precipitate is collected by centrifugati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com