Circulating trapping method and system for mercury in flue gas

A flue gas and circulating fluidized bed technology, applied in the direction of separation methods, chemical instruments and methods, and improvement of process efficiency, can solve the problems of difficulty in recovery of potential risk mercury resources, increase of residual mercury content, high cost of mercury removal, etc., to achieve Ease of recycling, ease of recovery, and high regeneration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

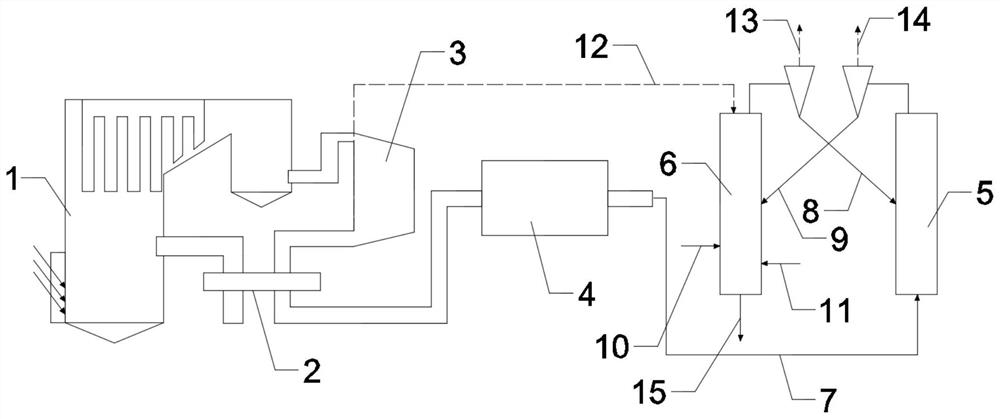

[0039] like figure 1 As shown, this embodiment discloses the first embodiment of the present invention, and the technical solution adopted is, including the following steps:

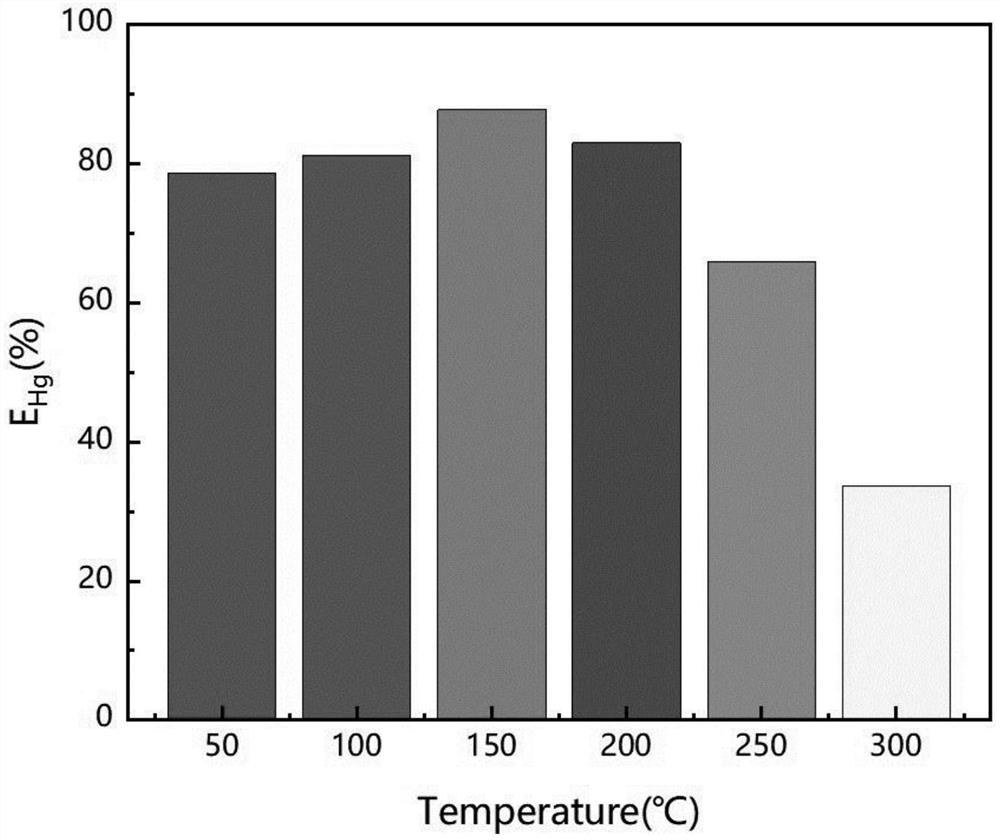

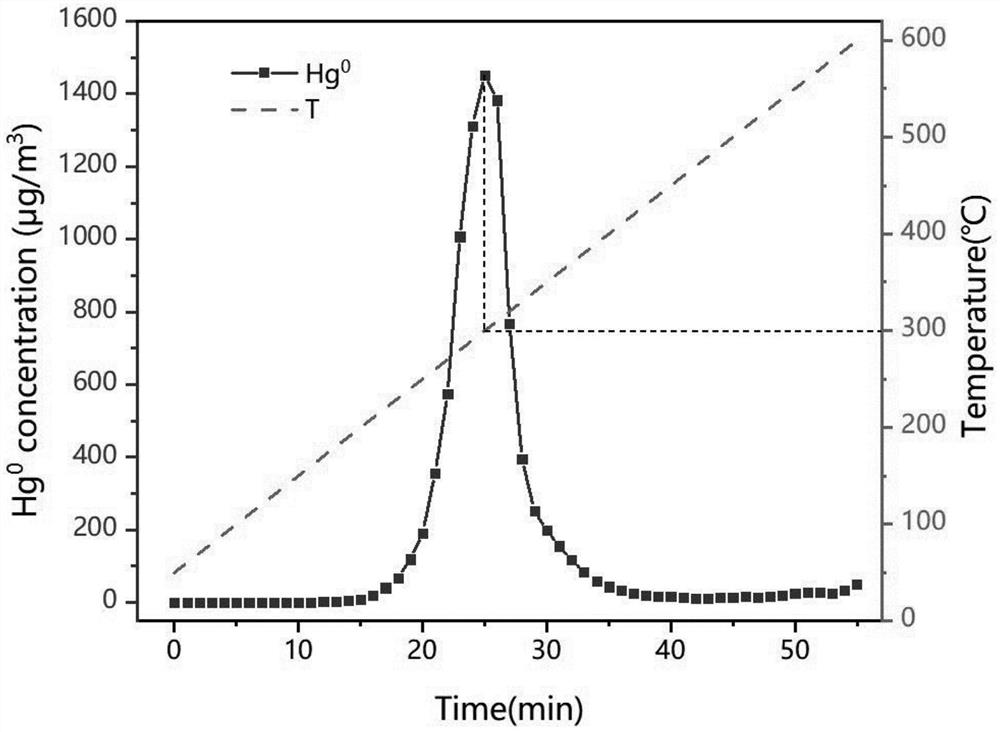

[0040] In step 1, the flue gas generated by the boiler 1 of the circulating fluidized bed is denitrified by the selective catalytic reduction and denitration system 3, the air preheater 2 is preheated, and the electrostatic precipitator 4 is dedusted to obtain the mercury-containing flue gas 7, and the mercury-containing flue gas 7 is obtained. The gas 7 passes through a circulating fluidized bed adsorption furnace 5 equipped with a manganese-based perovskite oxide catalyst, and at a temperature of 150 ° C, the catalyst in the circulating fluidized bed adsorption furnace 5 adsorbs the mercury-containing flue gas 7 and is oxidized into a gas containing mercury. Adsorbed mercury oxide can get clean flue gas 14 and waste catalyst 9;

[0041] In step 2, the clean flue gas 14 and the waste catalyst 9 obtaine...

Embodiment approach

[0049] This embodiment discloses the second embodiment of the present invention, and the technical solution adopted is that it includes the following steps:

[0050] In step 1, the flue gas generated by the boiler 1 of the circulating fluidized bed is denitrified by the selective catalytic reduction and denitration system 3, the air preheater 2 is preheated, and the electrostatic precipitator 4 is dedusted to obtain the mercury-containing flue gas 7, and the mercury-containing flue gas 7 is obtained. The gas 7 passes through the circulating fluidized bed adsorption furnace 5 equipped with a catalyst, and at a temperature of 200° C., the catalyst in the circulating fluidized bed adsorption furnace 5 adsorbs the mercury-containing flue gas 7 and is oxidized into the mercury oxide in the adsorbed state. Clean flue gas 14 and waste catalyst 9;

[0051] In step 2, the clean flue gas 14 and the waste catalyst 9 obtained in the step 1 are passed into the first cyclone separator for g...

Embodiment 3

[0059] This embodiment discloses the third embodiment of the present invention, and the technical solution adopted is that it includes the following steps:

[0060] In step 1, the flue gas generated by the boiler 1 of the circulating fluidized bed is denitrified by the selective catalytic reduction and denitration system 3, the air preheater 2 is preheated, and the electrostatic precipitator 4 is dedusted to obtain the mercury-containing flue gas 7, and the mercury-containing flue gas 7 is obtained. The gas 7 passes through the circulating fluidized bed adsorption furnace 5 equipped with a catalyst, and at a temperature of 175° C., the catalyst in the circulating fluidized bed adsorption furnace 5 adsorbs the mercury-containing flue gas 7 and is oxidized into the mercury oxide in the adsorbed state. Clean flue gas 14 and waste catalyst 9;

[0061] In step 2, the clean flue gas 14 and the waste catalyst 9 obtained in the step 1 are passed into the first cyclone separator for ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com