Ceramic phenolic aerogel and preparation method thereof

A ceramicization and aerogel technology, applied in the direction of body insulation, weight reduction, etc., can solve the problems of low carbon residue rate of phenolic aerogel and cannot be used for a long time, so as to reduce the collapse of holes and improve the rate of carbon residue. , Improve the effect of heat insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

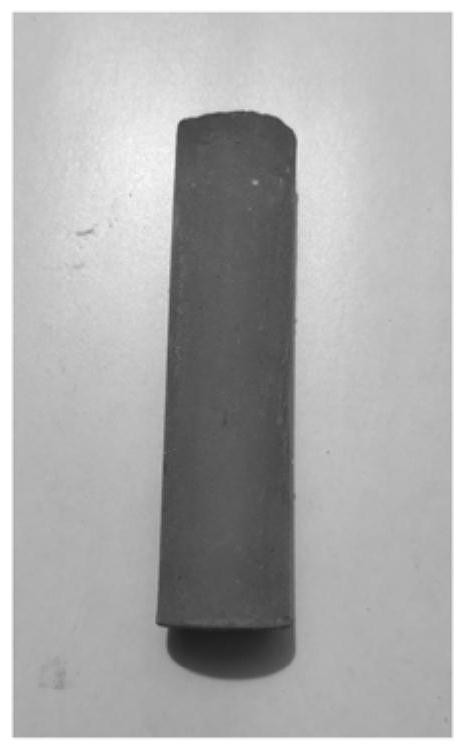

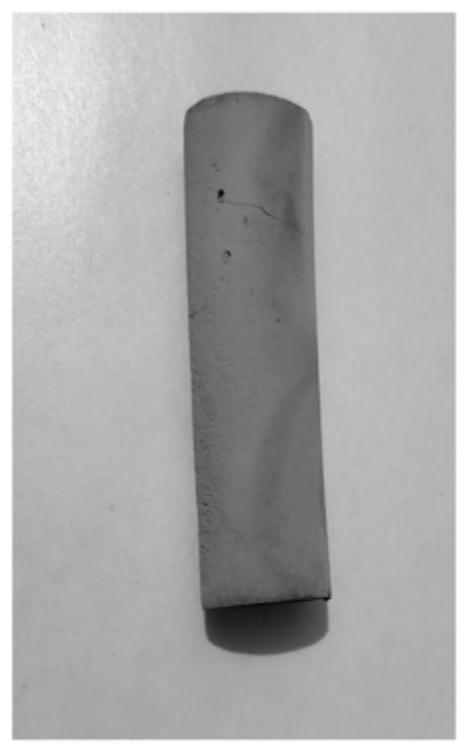

Embodiment 1

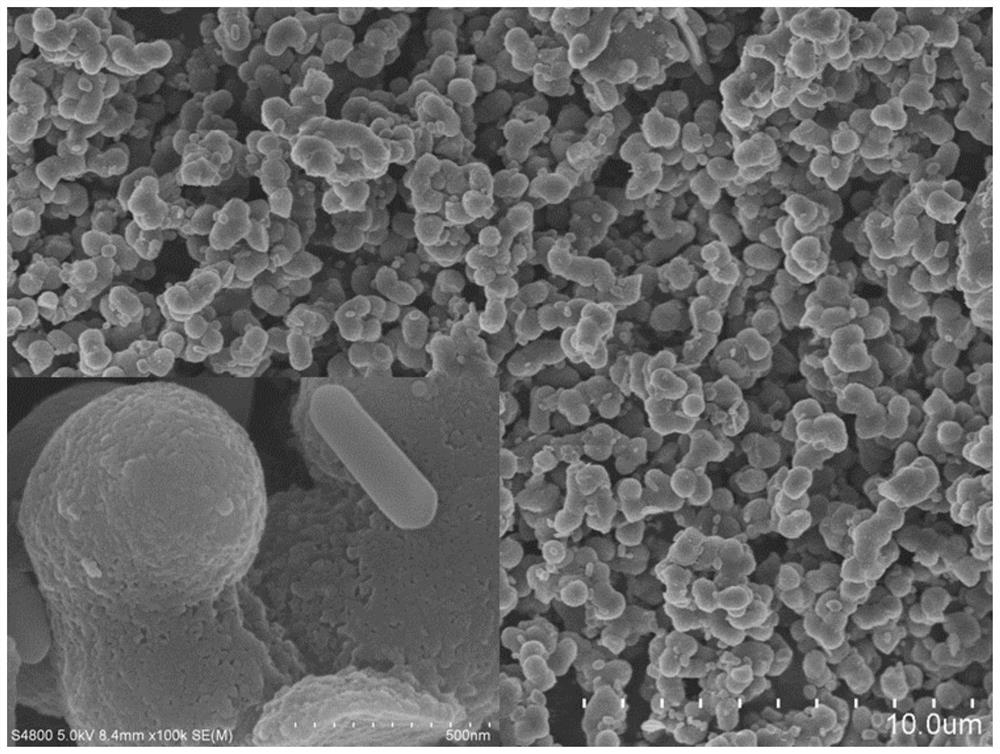

[0029] A preparation method of ceramizable phenolic aerogel, the steps are as follows:

[0030] (1) Resorcinol, formaldehyde (in actual use, the formaldehyde solution produced by Shanghai Aladdin Reagent Co., Ltd., the mass fraction is 37wt%) and deionized water are mixed at 25 ° C according to the molar ratio of 1:3:13 , the precursor solution was obtained after stirring for 15 min, and the total mass of resorcinol and formaldehyde was recorded as 100 parts. TiB 2 Powder and B 4 The C powder was mixed uniformly at a mass ratio of 1:1 to prepare a ceramizable filler, 10 parts of the ceramizable filler were added to the precursor solution, and a suspension was obtained after stirring for 10 minutes, and the suspension was transferred into the mold.

[0031] (2) adding trifluoroacetic acid accounting for 5% of the suspending liquid fraction into the mold, after 15-40 s of sol-gel reaction, the gel can be gelled, and then the aging reaction is continued for 1 h to obtain a cera...

Embodiment 2

[0033] A preparation method of ceramizable phenolic aerogel, the steps are as follows:

[0034] (1) Mix resorcinol, formaldehyde and deionized water at 25°C according to a molar ratio of 1:3:13, obtain a precursor solution after stirring for 20min, and record the mass sum of resorcinol and formaldehyde as 100 share. TiB 2 Powder and B 4 The C powder was uniformly mixed at a mass ratio of 1:1 to prepare a ceramizable filler, 30 parts of the ceramizable filler was added to the precursor solution, and a suspension was obtained after stirring for 20 minutes, and the suspension was transferred into the mold.

[0035] (2) adding trifluoroacetic acid accounting for 5% of the suspending liquid fraction into the mold, after 15-40 s of sol-gel reaction, the gel can be gelled, and then the aging reaction is continued for 1 h to obtain a ceramizable phenolic hydrogel. The ceramizable phenolic hydrogel was demolded and placed in a drying oven for drying at atmospheric pressure step-up h...

Embodiment 3

[0037] A preparation method of ceramizable phenolic aerogel, the steps are as follows:

[0038] (1) Mix resorcinol, formaldehyde and deionized water at 25°C according to a molar ratio of 1:3:13, obtain a precursor solution after stirring for 20min, and record the mass sum of resorcinol and formaldehyde as 100 share. TiB 2 Powder and B 4 The C powder was uniformly mixed at a mass ratio of 1:1 to prepare a ceramizable filler, and 50 parts of the ceramizable filler was added to the precursor solution, stirred for 20 minutes to obtain a suspension, and the suspension was transferred into the mold.

[0039] (2) adding trifluoroacetic acid accounting for 5% of the suspending liquid fraction into the mold, after 15-40 s of sol-gel reaction, the gel can be gelled, and then the aging reaction is continued for 1 h to obtain a ceramizable phenolic hydrogel. The ceramizable phenolic hydrogel was demolded and placed in a drying oven for drying at atmospheric pressure step-up heating. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com