CuO microsphere and antibacterial PPSU composite material and preparation method thereof

A composite material and microsphere technology, applied in copper oxide/copper hydroxide and other directions, can solve the problems of no antibacterial properties and limited application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

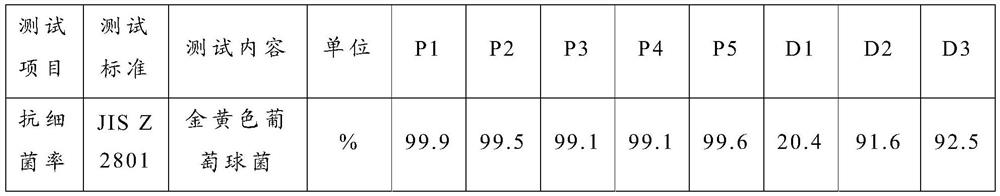

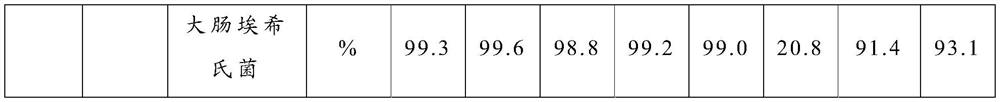

Examples

preparation example Construction

[0041] The present invention also provides a preparation method of the above-mentioned antibacterial PPSU composite material, comprising the following steps:

[0042] 1) mixing PPSU, antibacterial agent and antioxidant to obtain a mixture;

[0043] 2) The mixture is extruded and granulated to obtain an antibacterial PPSU composite material.

[0044] In the present invention, the extrusion granulation is preferably carried out in a twin-screw extruder. The twin-screw extruder preferably adopts six temperature zones arranged in sequence during extrusion and granulation, which are respectively: the temperature of the first zone is 290-330°C, the temperature of the second zone is 310-350°C, and the temperature of the third zone is 310°C. ~350℃, the temperature of the fourth zone is 310~350℃, the temperature of the fifth zone is 310~350℃, the temperature of the sixth zone is 310~350℃; the temperature of the head of the twin-screw extruder is 310~350℃, and the screw speed is 200~28...

Embodiment 1

[0049] (1) take by weighing 80 parts of PPSU, 2 parts of antibacterial agent M1, 0.2 part of antioxidant 9960 and mix and stir to obtain mixture;

[0050] (2) Extruding and granulating the mixture obtained in step (1) from an extruder to obtain PPSU composite material P1.

[0051] The twin-screw extruder includes six temperature zones arranged in sequence, the temperature of the first zone is 290°C, the temperature of the second zone is 320°C, the temperature of the third zone is 330°C, the temperature of the fourth zone is 330°C, the temperature of the fifth zone is 330°C, and the temperature of the sixth zone is 330°C. 330℃, head temperature 330℃, screw speed 230r / min.

[0052] Wherein the antibacterial agent M1 adopts the following steps to prepare:

[0053] (1) Weigh 300g of copper nitrate, 1.2kg of deionized water, 100g of sodium hydroxide, 200g of ammonia water, and 200g of gas-phase titanium dioxide, add them to a reaction vessel, and react at 50°C for 10h to obtain mi...

Embodiment 2

[0058] (1) take by weighing 90 parts of PPSU, 3 parts of antibacterial agent M2, 0.1 part of antioxidant 1098, 0.2 part of antioxidant 9228, 0.2 part of antioxidant 1330 and mix and stir to obtain a mixture;

[0059] (2) Extruding and granulating the mixture obtained in step (1) from an extruder to obtain PPSU composite material P2.

[0060] The twin-screw extruder includes six temperature zones arranged in sequence, the temperature of the first zone is 310°C, the temperature of the second zone is 330°C, the temperature of the third zone is 330°C, the temperature of the fourth zone is 330°C, the temperature of the fifth zone is 330°C, and the temperature of the sixth zone is 330°C. 330℃, head temperature 330℃, screw speed 240r / min.

[0061] Wherein the antibacterial agent M2 is prepared by the following steps:

[0062] (1) Weigh 350g copper nitrate, 1.4kg deionized water, 130g sodium hydroxide, 220g ammonia water, 250g gas phase titanium dioxide, add them to the reaction vess...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com