NANO silver collosol preparing method

A technology of nano-silver sol and silver-ammonia solution, which is applied in the direction of nanotechnology to achieve excellent stability, ensure application safety, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Get 0.1g polylysine and dissolve it in 100ml deionized water to obtain a polylysine aqueous solution with a mass percentage of 0.1%;

[0020] Prepare a 1mol / L silver nitrate solution, then add dropwise ammonia water with a concentration of 20% until the initial precipitate is just dissolved (ammonia water is not too much), to obtain a silver ammonia solution, dilute to a mass molar concentration of 0.05mol / L;

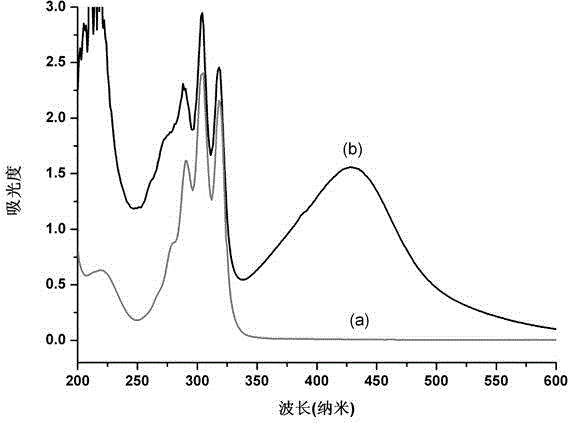

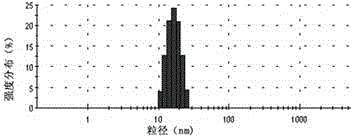

[0021] Add 1ml of silver ammonia solution with a mass molar concentration of 0.05mol / L dropwise into 50ml of a polylysine aqueous solution with a mass percent concentration of 0.1%, adjust the pH to 11, and stir and react at 80°C for 60min to obtain brown-yellow silver nanoparticles Sol, wherein the particle size of nano-silver is 10-30nm. Test the UV-Vis spectrum after diluting the prepared nano-silver sol, the results are as follows: figure 1 Shown; Nano-silver sol has an obvious strong absorption peak at 420nm, and this absorption peak is produced by nano-sil...

Embodiment 2

[0023] Get 0.5g polylysine and dissolve it in 100ml deionized water to obtain a polylysine aqueous solution with a mass percentage of 0.5%;

[0024] Prepare a 1mol / L silver nitrate solution, and then add dropwise ethylenediamine with a concentration of 10% until the initial precipitate is just dissolved (the ethylenediamine is not too much) to obtain a silver ammonia solution, which is diluted to a mass molar concentration of 0.1mol / L L;

[0025] Add 1 ml of silver ammonia solution with a mass molar concentration of 0.1 mol / L dropwise into 30 ml of a polylysine aqueous solution with a mass percent concentration of 0.5%, adjust the pH to 12, and stir and react at 60°C for 120 minutes to obtain brown nano-silver Sol, wherein the particle size of nano-silver is 10-30nm.

Embodiment 3

[0027] Get 0.1g polylysine and dissolve it in 100ml deionized water to obtain a polylysine aqueous solution with a mass percentage of 0.1%;

[0028] Prepare a 1mol / L silver nitrate solution, then add dropwise diethylenetriamine with a concentration of 10% until the initial precipitate disappears (diethylenetriamine is not excessive), and obtain a silver ammonia solution, which is diluted to a mass molar concentration of 0.01mol / L;

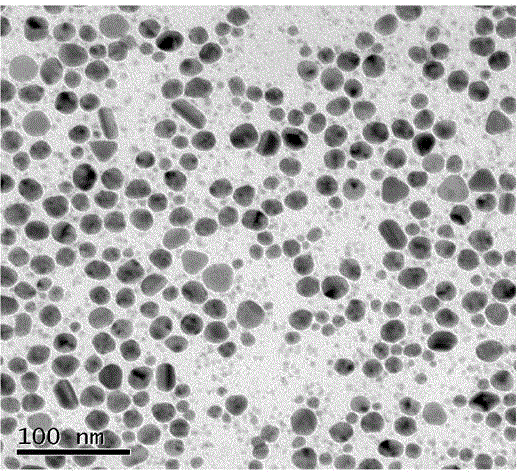

[0029] Add 1ml of silver ammonia solution with a mass molar concentration of 0.01mol / L dropwise into 50ml of a polylysine aqueous solution with a mass percentage concentration of 0.1%, adjust the pH to 11.5, and stir and react at 100°C for 30min to obtain a nano-silver sol. The sol is yellow. image 3 It is the TEM picture of nano-silver. It can be seen from the figure that the nano-silver particles are basically spherical in structure, with a particle size of about 20-30nm. The nano-silver particles are evenly dispersed without agglomeration.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com