Silicon-free high-temperature-resistant protective adhesive film and preparation method thereof

A high temperature resistant and adhesive film technology, applied in the direction of adhesives, polymer adhesive additives, film/sheet adhesives, etc., can solve the problems of film performance stability and mechanical properties that need to be further improved, to avoid Effects of silicon transfer, improvement of physical properties, and ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

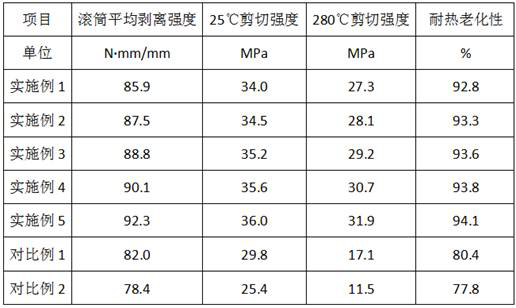

Examples

Embodiment 1

[0023] A silicon-free high temperature resistant protective adhesive film comprises a base material layer, an adhesive layer and a silicon-free release film layer in sequence from top to bottom; the base material layer is a polybenzimidazole film layer; the adhesive The layer is made of the following components in parts by weight: 30 parts of hyperbranched polybenzimidazoles whose end groups are amino groups, 5 parts of acetylated modified polyphenylene sulfide, 2,2-bis(3-amino- 4-hydroxyphenyl) hexafluoropropane 2 parts, titanate coupling agent 1 part, acetic acid 1 part, molecular sieve 3 parts, solvent 60 parts.

[0024] The titanate coupling agent is titanate coupling agent NXH-501; the molecular sieve is type 3A molecular sieve; the solvent is N,N-dimethylformamide; the silicon-free release film layer is Made of silicon-free release film RF3220.

[0025] A preparation method of the silicon-free high temperature resistant protective adhesive film, comprising the following...

Embodiment 2

[0027] A silicon-free high temperature resistant protective adhesive film comprises a base material layer, an adhesive layer and a silicon-free release film layer in sequence from top to bottom; the base material layer is a polybenzimidazole film layer; the adhesive The layer is made of the following components in parts by weight: 33 parts of hyperbranched polybenzimidazoles whose end groups are amino groups, 6 parts of acetylated modified polyphenylene sulfide, 2,2-bis(3-amino- 2.5 parts of 4-hydroxyphenyl) hexafluoropropane, 1.2 parts of titanate coupling agent, 1.3 parts of acetic acid, 3.5 parts of molecular sieves, and 65 parts of solvent.

[0028] The titanate coupling agent is titanate coupling agent 201; the molecular sieve is type 4A molecular sieve; the solvent is N,N-dimethylacetamide; the silicon-free release film layer is made of Any of silicon release film RF3220 and PET non-silicon release film GT-989.

[0029] Another object of the present invention is to prov...

Embodiment 3

[0031] A silicon-free high temperature resistant protective adhesive film comprises a base material layer, an adhesive layer and a silicon-free release film layer in sequence from top to bottom; the base material layer is a polybenzimidazole film layer; the adhesive The layer is made of the following components in parts by weight: 35 parts of hyperbranched polybenzimidazole with amino end groups, 7.5 parts of acetylated modified polyphenylene sulfide, 2,2-bis(3-amino- 4-hydroxyphenyl) hexafluoropropane 3 parts, titanate coupling agent 1.5 parts, acetic acid 1.5 parts, molecular sieve 4 parts, solvent 70 parts.

[0032] The titanate coupling agent is titanate coupling agent NXH-501; the molecular sieve is type 5A molecular sieve; the solvent is N-methylpyrrolidone; the silicon-free release film layer is made of PET non-silicon The release film is made of GT-989.

[0033] A preparation method of the silicon-free high temperature resistant protective adhesive film, comprising th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com