Nanometer titanium dioxide solid particle emulsifier and preparation method thereof

A nano-titanium dioxide, solid particle technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of narrow application range, low emulsion phase transition point, etc., and achieve the effect of strong industrializability and simple synthesis method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

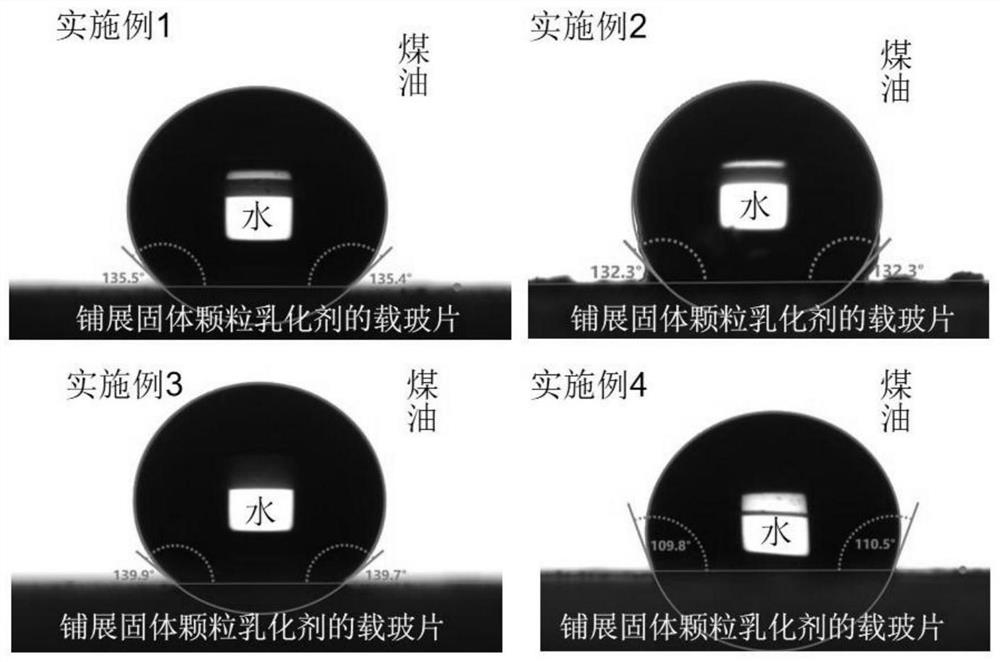

Embodiment 1

[0023] (1) Add 100 g of absolute ethanol and 3 g of hydrophilic titanium dioxide to the reagent bottle, and ultrasonically prepare the dispersion for 30 minutes.

[0024] (2) Add 0.3 g of isopropyl tris (dioctyl pyrophosphate acyloxy) titanate (purchased by Nanjing Nengde New Material Technology Co., Ltd.) into the dispersion, and put it into an oil bath at 65°C Heat and stir for 12 hours.

[0025] (3) in the dispersion liquid in the step 2, drip 3g bromododecan, shake the reagent bottle in the dripping process, ensure that the reaction system is mixed evenly; After the end, the product is subjected to suction filtration, washing treatment, drying and grinding to obtain the nano solid particle emulsifier S1.

Embodiment 2

[0027] (1) Add 100 g of absolute ethanol and 3 g of hydrophilic titanium dioxide to the reagent bottle, and ultrasonically prepare the dispersion for 30 minutes.

[0028] (2) 0.3 g of bis(dioctyl pyrophosphate acyloxy) ethylene titanate (purchased by Nanjing Nengde New Material Technology Co., Ltd.) was added to the dispersion, and heated in an oil bath at 65°C and stirred for 12 hours.

[0029] (3) 3g of bromododecan was added dropwise to the dispersion in step 2, and the reagent bottle was shaken during the dropwise addition to ensure that the reaction system was evenly mixed; put into an oil bath at 65°C and heated and stirred for 12 hours. After the reaction, the product is subjected to suction filtration, washing treatment, drying and grinding to obtain nano solid particle emulsifier S2.

Embodiment 3

[0031] (1) Add 100 g of absolute ethanol and 3 g of hydrophilic titanium dioxide to the reagent bottle, and ultrasonically prepare the dispersion for 30 minutes.

[0032] (2) 0.3 g of isopropoxydioleic acid acyloxy (dioctyl phosphoric acid acyloxy) titanate (purchased by Nanjing Nengde New Material Technology Co., Ltd.) was added to the dispersion liquid, and put into 65°C Heat and stir in an oil bath for 12 hours.

[0033] (3) 3g of bromohexadecane was added dropwise to the dispersion in step 2, and the reagent bottle was shaken during the dropwise addition to ensure that the reaction system was evenly mixed; put into an oil bath at 65°C and heated and stirred for 12 hours. After the reaction, the product is subjected to suction filtration, washing treatment, drying and grinding to obtain nano solid particle emulsifier S3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com