Method for preparing high-strength and high-hardness nano hard alloy

A cemented carbide, high hardness technology, used in metal processing equipment, transportation and packaging, etc., can solve the problems of uneven compounding, complex process, grain growth, etc., and achieve good monodispersity, product purity, and composition ratio. adjustable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

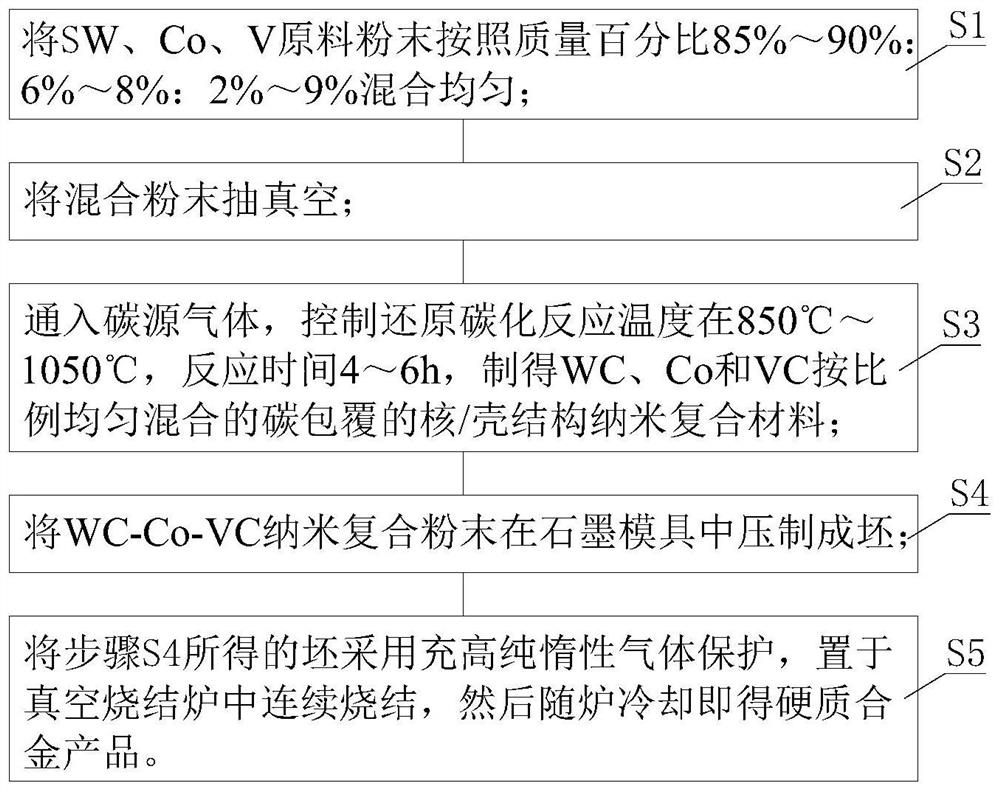

[0033] like figure 1 As shown, the method for preparing high-strength, high-hardness nano-hard alloy:

[0034] First, accurately weigh W, Co, V (86%: 8%: 6%) raw material powders according to a certain mass ratio. The diameter of the W powder particles is 50-200 nm, and the diameter of the Co powder particles is 200-400 nm. The diameter of the V powder particles ranges from 100 to 500 nm.

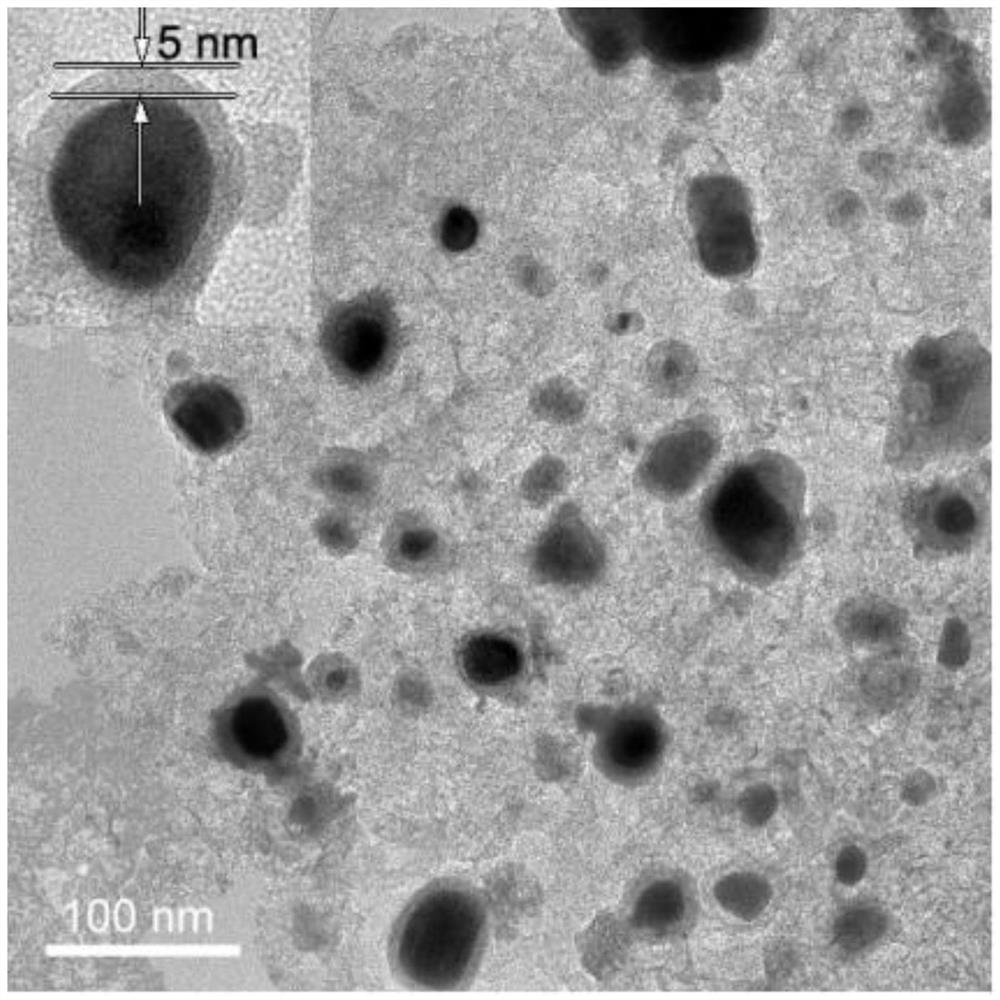

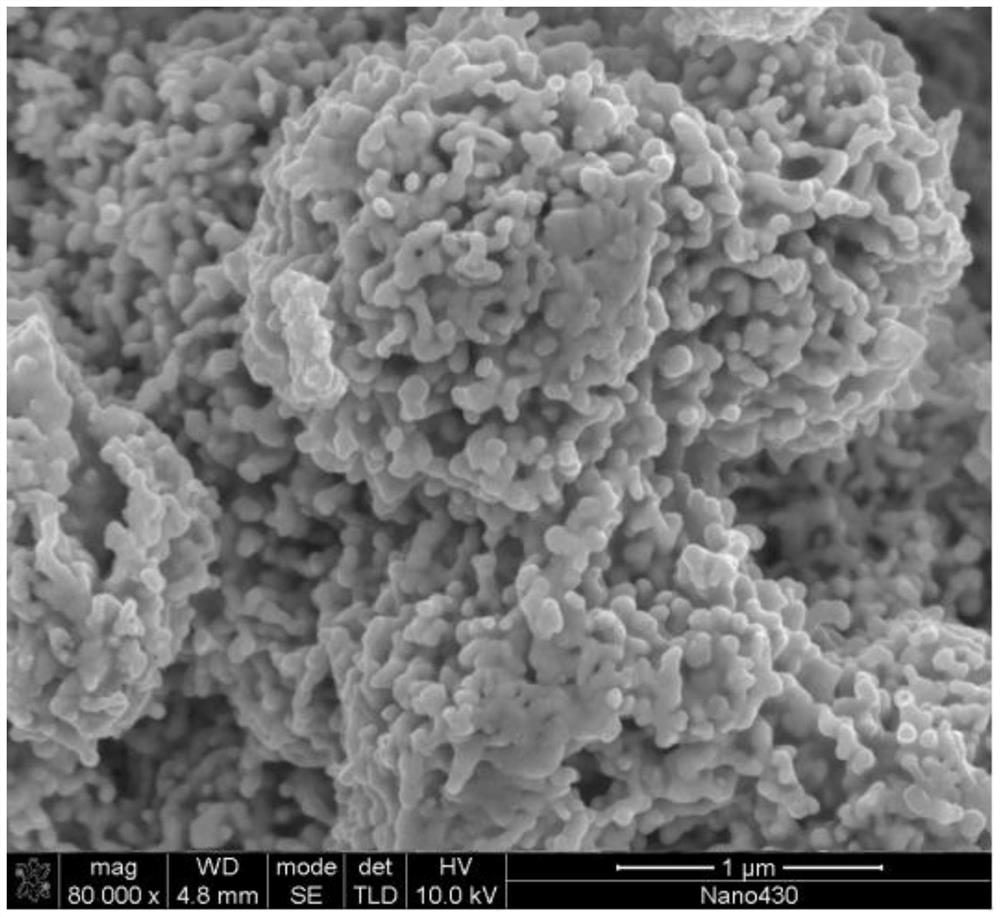

[0035] Vacuum to make the vacuum degree higher than 10 -3 Pa, then feed methane gas, control the flow rate of methane gas to be 6L / min, control the reduction carbonization reaction temperature to be 950°C, and the reaction time to be 6 hours. Thereby, a carbon-coated core / shell structure nanocomposite in which WC, Co, and VC are uniformly mixed in proportion is prepared.

[0036] The WC-Co-VC nanocomposite powder was pressed into a blank in a graphite mold, and the pressure range was controlled to 45MPa.

[0037] The blank obtained in the previous step is protected with high-purity iner...

Embodiment 2

[0039] like figure 1 As shown, the method for preparing high-strength, high-hardness nano-hard alloy:

[0040] First, accurately weigh W, Co, V (88%: 7%: 5%) raw material powder according to a certain mass ratio, the diameter of W powder particles is 200-400nm, and the diameter of Co powder particles is 400-500nm, The diameter of the V powder particles ranges from 500 to 800 nm.

[0041] Vacuum to make the vacuum degree higher than 10 -3Pa, then feed methane gas, control the flow rate of acetylene gas to be 8L / min, control the reduction carbonization reaction temperature to be 1000°C, and the reaction time to be 5 hours. Thereby, a carbon-coated core / shell structure nanocomposite in which WC, Co, and VC are uniformly mixed in proportion is prepared.

[0042] The WC-Co-VC nanocomposite powder was pressed into a blank in a graphite mold, and the pressure range was controlled to 35MPa.

[0043] The blank obtained in the previous step is protected by high-purity inert gas (arg...

Embodiment 3

[0045] like figure 1 As shown, the method for preparing high-strength, high-hardness nano-hard alloy:

[0046] First, accurately weigh W, Co, V (90%: 6%: 4%) raw material powders according to a certain mass ratio. The diameter of the W powder particles is 400-500 nm, and the diameter of the Co powder particles is 500-600 nm. The diameter of the V powder particles ranges from 800 to 1000 nm.

[0047] Vacuum to make the vacuum degree higher than 10 -3 Pa, then feed methane gas, control the flow rate of ethylene gas to be 10L / min, control the reduction carbonization reaction temperature to be 1050°C, and the reaction time to be 4 hours. Thereby, a carbon-coated core / shell structure nanocomposite in which WC, Co, and VC are uniformly mixed in proportion is prepared.

[0048] The WC-Co-VC nanocomposite powder was pressed into a blank in a graphite mold, and the pressure range was controlled to 50MPa.

[0049] The blank obtained in the previous step is protected with high-purity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com