Method for extracting and purifying glyphosate residue in vegetable oil

A technology for glyphosate and vegetable oil, which is applied in the field of pretreatment for the determination of pesticide residues, can solve the problems of lack of fluorescent and chromophoric groups, long pretreatment time, and long reaction time, so as to reduce the types of reagents, shorten the time, The effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

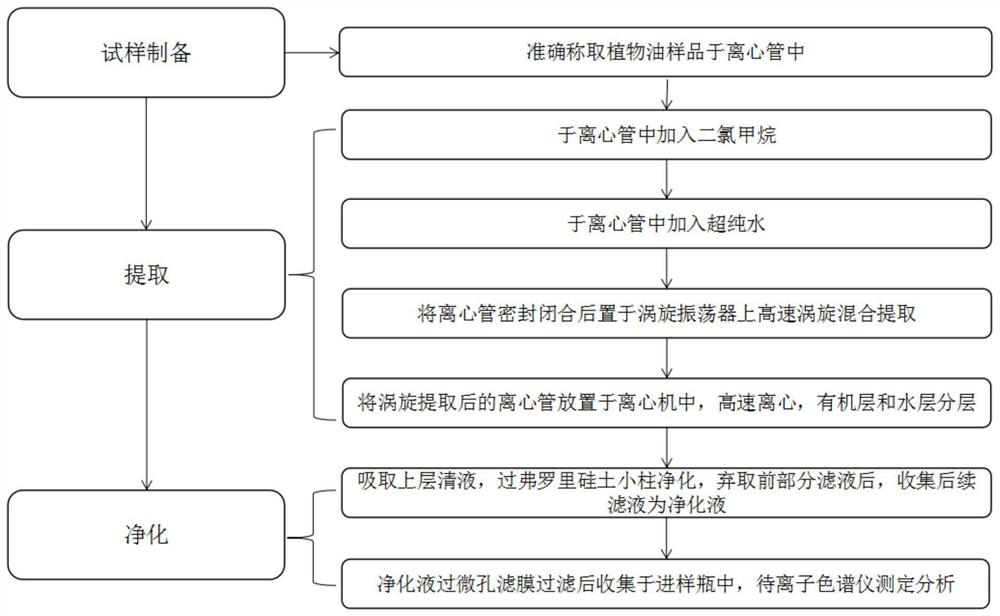

[0039] A kind of extraction and purification method of glyphosate residue in vegetable oil, such as figure 1 shown, including the following steps:

[0040] (1) Mix the Camellia oleifera seed oil sample evenly, accurately weigh 1.00g of Camellia oleifera seed oil sample in a 10mL centrifuge tube;

[0041] (2) Add 2 mL of dichloromethane (chromatographically pure) to the centrifuge tube;

[0042] (3) Add 5 mL of ultrapure water to the centrifuge tube;

[0043] (4) Seal the centrifuge tube and place it on a vortex shaker for high-speed vortex mixing and extraction for 40s;

[0044](5) place the centrifuge tube after the vortex extraction in the centrifuge, and centrifuge at high speed (centrifugal force 10000×g) for 3 minutes to quickly stratify the organic layer and the water layer;

[0045] (6) Absorb the supernatant liquid (that is, the aqueous solution of glyphosate), pass it through a Florisil column (the specification of the Florisil cartridge is 1000 mg, 6 mL) to purify...

Embodiment 2

[0064] Compared with Example 1, the difference between this example is that in this example, 1000 mg / L high-concentration glyphosate standard solution was added to the Camellia oleifera seed oil sample to form a glyphosate concentration of 5.0 mg / kg and 3.0 mg. / kg and 1.0mg / kg camellia seed oil spiked samples, respectively accurately weighed three glyphosate concentrations of camellia seed oil spiked samples 1.00g in three 10mL centrifuge tubes, and according to Example 1 (2 (2) The steps of )-(6) carry out pretreatment analysis, and the equipment and chromatographic conditions are consistent with those in Example 1.

[0065] The detection method of the ion chromatograph is the prior art, which will not be repeated here. The purified solution after three kinds of camellia seed oil spiked samples with different glyphosate concentrations are put into the injection bottle and detected by the ion chromatograph to obtain Glyphosate was detected in camellia seed oil spiked samples ...

Embodiment 3

[0067] Compared with Example 1, the difference between this example is that in this example, a high-concentration glyphosate standard solution is added to the camellia seed oil sample to form a camellia seed oil spiked sample with a glyphosate concentration of 1.0 mg / kg. , after mixing evenly, accurately weigh 1.00g of Camellia oleifera seed oil spiked sample in a 10mL centrifuge tube, and carry out pretreatment analysis according to the steps of (2)-(6) in Example 1. Instruments and chromatographic conditions and examples If 1 is consistent, measure the recovery rate, repeat twice, and take the average value of the recovery rate to avoid accidental errors.

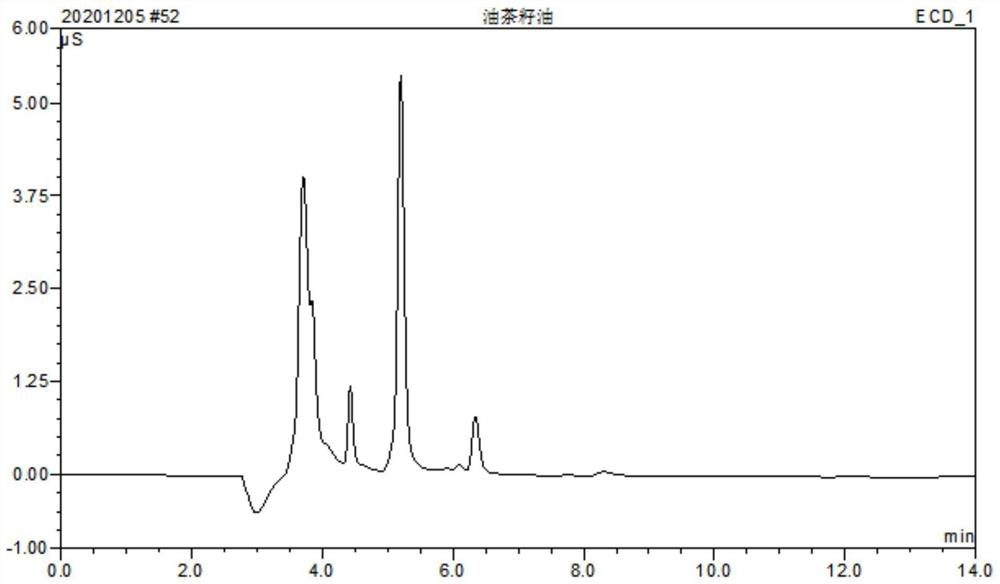

[0068] The detection method of the ion chromatograph is the prior art, which will not be repeated here. The purified solution of the camellia seed oil spiked sample is put into a sample injection bottle and detected by the ion chromatograph to obtain the camellia seed oil spiked sample. The chromatogram of glyphosate dete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com