Freeze-dried instant fish meat product and preparation method thereof

A fish meat and freeze-drying technology, which is applied in food preservation, meat/fish preservation, food science, etc., can solve the problems of long rehydration time and low rehydration rate of fish meat, and achieve rich fish flavor, high rehydration rate, The effect of shortening the rehydration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

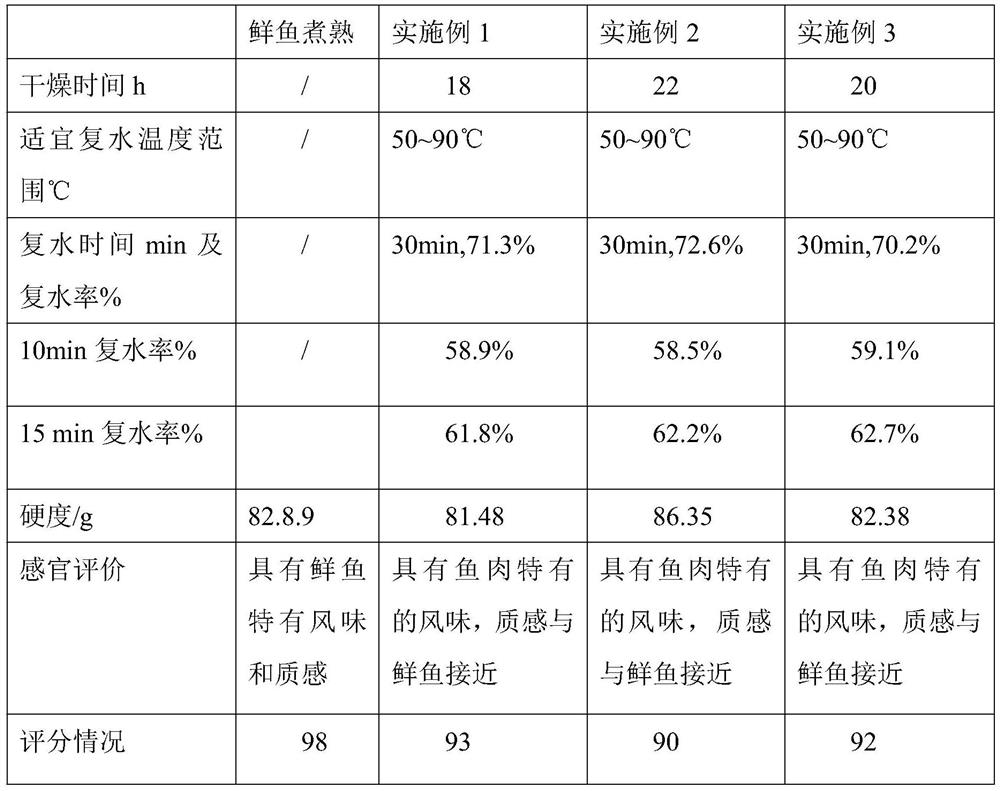

Embodiment 1

[0029] (1) Peel the back muscles of the tilapia, remove the intermuscular bone spurs, cut into pieces 3cm×3cm, and wash with drinking water;

[0030] (2) Put sterile water into the soaking tank, adjust the water temperature to about 4°C, add sodium chloride to a mass concentration of 4%, food-grade trehalose to a mass concentration of 4%, soybean polysaccharide 3%, propylene glycol 2%, and after cleaning Put the fish pieces into the water tank, the quality of the soaking liquid is 1.5 times the quality of the fish meat, and the soaking time is 60min;

[0031] (3) Heat the fish pieces in a 100°C water bath for 1 min, take out the fish pieces, and freeze them below -18°C.

[0032] (4) Dry the frozen fish pieces in a cold trap temperature of -40°C and a vacuum degree of 90pa.

Embodiment 2

[0034] (1) Peel the back muscles of the pangasius, remove the intermuscular bone spurs, cut into pieces, and clean them with drinking water;

[0035] (2) Put sterile water into the soaking tank, adjust the water temperature to about 8°C, add sodium chloride to a mass concentration of 3%, food-grade trehalose to a mass concentration of 2%, soybean polysaccharide 2%, propylene glycol 3%, and after cleaning Put the fish pieces into the water tank, the quality of the soaking liquid is 2 times that of the fish meat, and the soaking time is 50min;

[0036] (3) Steam the fish pieces for 1 min, take out the fish pieces, and freeze them below -18°C.

[0037] (4) Dry the frozen fish pieces in a cold trap with a temperature of -70°C and a vacuum of 90pa.

Embodiment 3

[0039] (1) peeling the back muscles of the snakehead, removing the intermuscular bone spurs, cutting into pieces, and cleaning with drinking water;

[0040] (2) Put sterile water into the soaking tank, adjust the water temperature to about 10°C, add sodium chloride to a mass concentration of 1%, food-grade trehalose to a mass concentration of 3%, soybean polysaccharide 2%, propylene glycol 4%, and after cleaning Put the fish pieces into the water tank, the quality of the soaking liquid is 2 times the quality of the fish meat, and the soaking time is 40min;

[0041] (3) The fish pieces were heated in a 90°C water bath for 2 minutes, and the fish pieces were taken out and frozen at -18°C.

[0042] (4) The frozen fish pieces were dried under the conditions of cold trap temperature -60°C and vacuum degree of 90pa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com