Forward osmosis-based chemical reactor

A chemical reactor and forward osmosis technology, applied in the field of chemical reactors based on forward osmosis, can solve the problems of insufficient universality of forward osmosis membrane reactors, and achieve good water flux, low membrane pollution and high permeation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

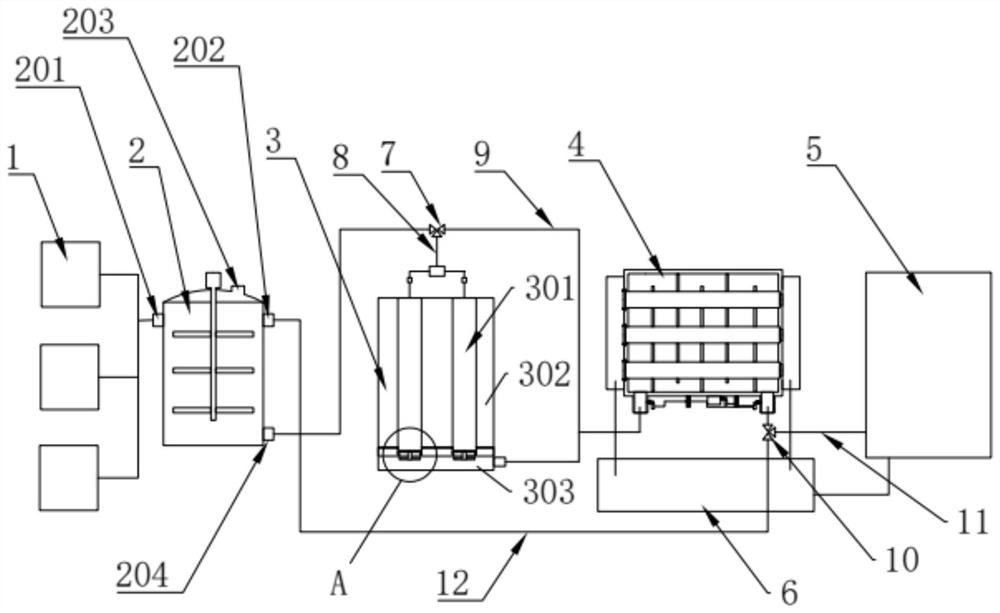

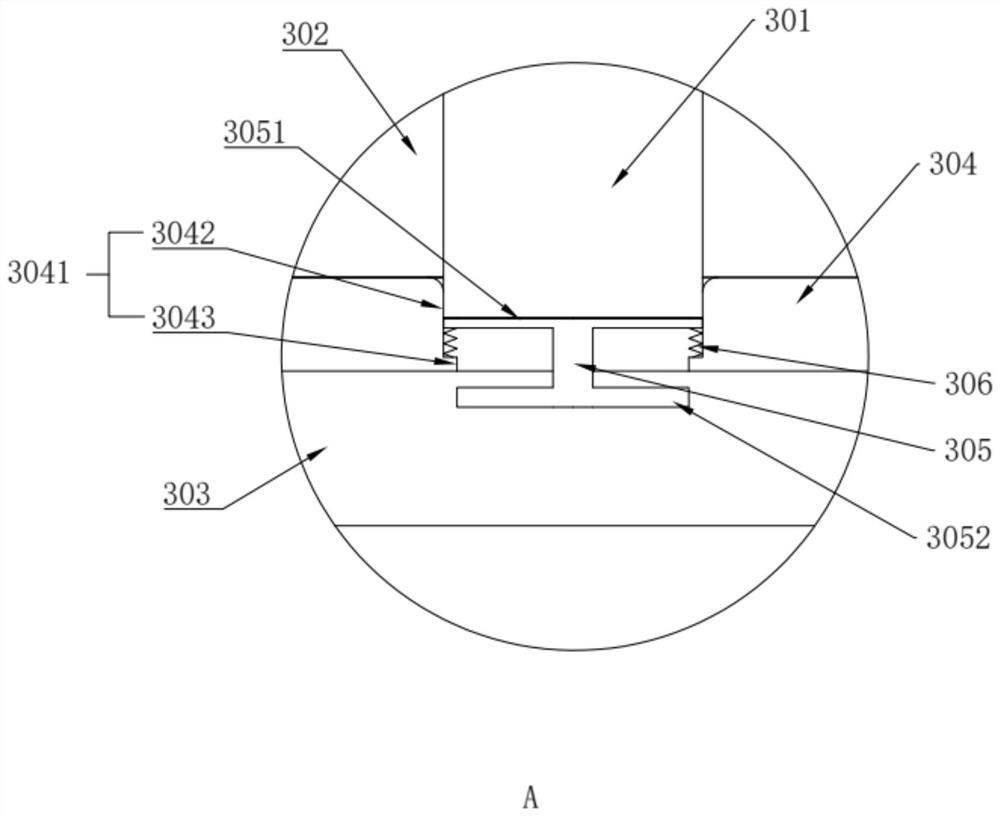

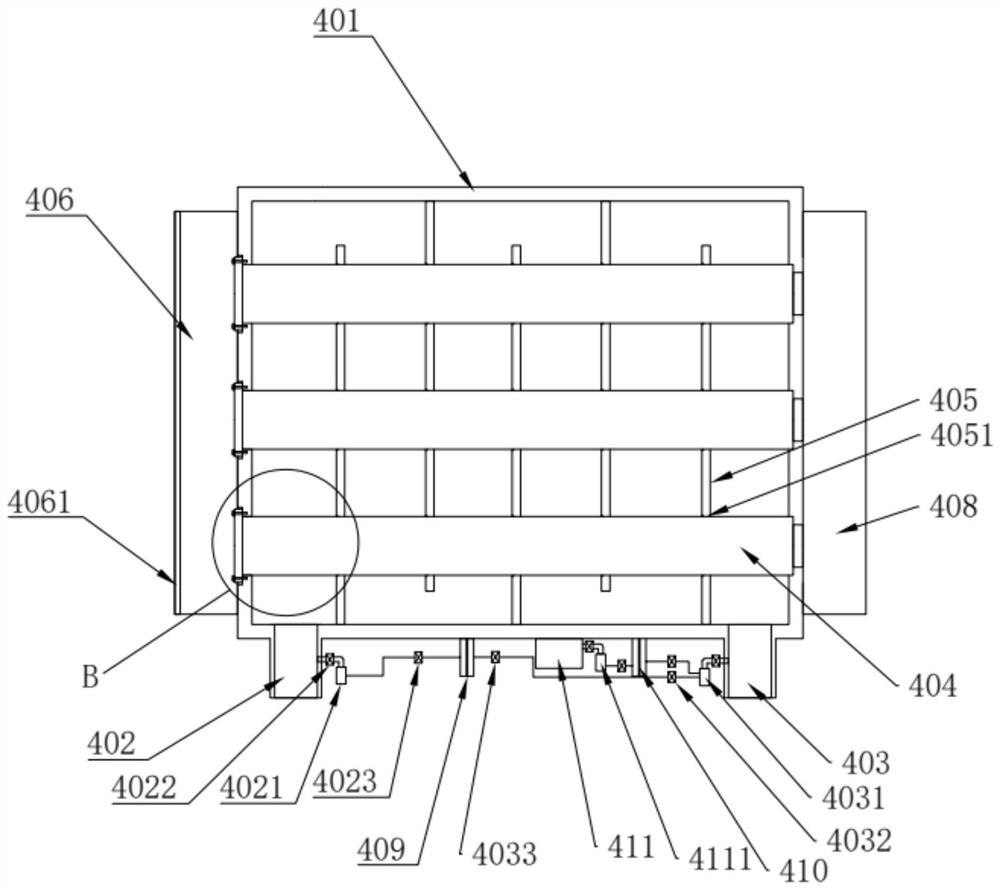

[0041] Example 1: A chemical reactor based on forward osmosis, such as figure 1 As shown, including raw material tank 1, reaction circulation tank 2, ultrafiltration tank 3, forward osmosis tank 4 and finished product tank 5, raw material tank 1 leads to reaction circulation tank 2, and forward osmosis tank 4 is connected with regeneration tank 6, regeneration tank 6 The extraction solution is regenerated by reverse osmosis, and the extraction solution in the forward osmosis tank 4 is supplemented, and the forward osmosis tank 4 leads to the finished product tank 5 and the reaction circulation tank 2 respectively;

[0042] The reaction circulation tank 2 includes a first addition port 201, a second addition port 202, an upper addition port 203 and a discharge port 204, the first addition port 201 is communicated with the raw material tank 1, and the upper addition port 203 is used for adding non-fluid raw materials and catalysts Equal a small amount of raw materials, the disch...

Embodiment 2

[0058] Example 2: The only difference between Example 2 and Example 1 is that the membrane material of the forward osmosis membrane is a solvent-resistant membrane material, and the preparation method of the solvent-resistant membrane material includes the following steps:

[0059] Step 1: take the PP film and soak the PP film with an organic solvent for 30min;

[0060] Step 2: take clean water to clean and soak the PP film for 10 minutes, take a 2% concentration of polyvinyl alcohol solution, and soak the PP film in a 2% concentration of polyvinyl alcohol solution for 30 minutes;

[0061] Step 3: take out the PP film, and soak the PP film in a 1% citric acid solution for 5min;

[0062] Step 4: Take out the PP film and drain the liquid on the surface, and add MPD aqueous phase solution with a concentration of 7% wt / v on the surface. After 10 minutes, take out the PP film, and use a rubber roller to remove the residual MPD water on the surface of the PP film. phase solution; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com