Quartz pot plasma meltallizing method suitable for physical vapor deposition process

A technology of physical vapor deposition and quartz pot, which is applied in ion implantation plating, metal material coating process, sputtering plating, etc., can solve the problems of general operation and reduced use effect, so as to increase maintenance times, improve service life, Effect of reducing loss of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

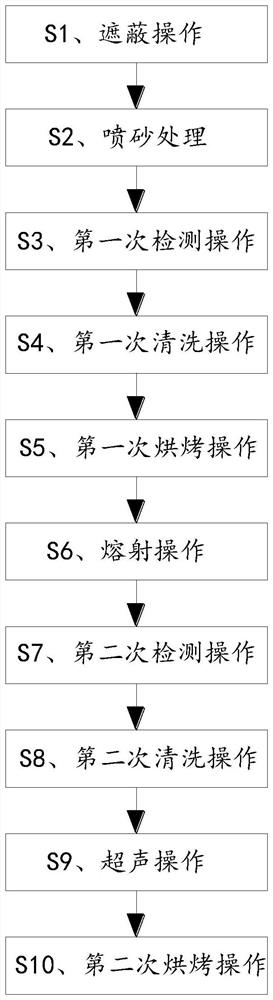

[0030] Example 1: Please refer to figure 1 As shown, the present invention discloses a quartz pot plasma spraying method suitable for physical vapor deposition process, comprising the following steps:

[0031] S1. Masking operation: Carry out self-inspection operation on the product to confirm whether the state of the product after removing the film reaches the sandblasting standard, mask the non-spraying area, and use 5cm wide hot melt tape to mask the edge of the quartz pot. The standard of sandblasting is to remove the film layer on the surface of the quartz pot cleanly, without bumps, pits and scratches;

[0032] S2. Sandblasting treatment: carry out self-inspection operation on the masked products in step S1 to confirm whether the masking is qualified, use 60# white corundum to sandblast the sprayed area, and use CDA to purge after sandblasting, not applicable The sandblasted area is completely masked with hot melt tape, and the interface of the tape is gentle. Sandblast...

Embodiment 2

[0041] Example 2: Please refer to figure 1 As shown, the present invention discloses a quartz pot plasma spraying method suitable for physical vapor deposition process, comprising the following steps:

[0042] S1. Masking operation: Carry out self-inspection operation on the product to confirm whether the state of the product after removing the film reaches the sandblasting standard, mask the non-spraying area, and use 5cm wide hot melt tape to mask the edge of the quartz pot. The standard of sandblasting is to remove the film layer on the surface of the quartz pot cleanly, without bumps, pits and scratches;

[0043] S2. Sandblasting treatment: carry out self-inspection operation on the masked products in step S1 to confirm whether the masking is qualified, use 60# white corundum to sandblast the sprayed area, and use CDA to purge after sandblasting, not applicable The sandblasted area is completely masked with hot melt tape, and the interface of the tape is gentle. Sandblast...

Embodiment 3

[0052] Example 3: Please refer to figure 1 As shown, the present invention discloses a quartz pot plasma spraying method suitable for physical vapor deposition process, comprising the following steps:

[0053] S1. Masking operation: Carry out self-inspection operation on the product to confirm whether the state of the product after removing the film reaches the sandblasting standard, mask the non-spraying area, and use 5cm wide hot melt tape to mask the edge of the quartz pot. The standard of sandblasting is to remove the film layer on the surface of the quartz pot cleanly, without bumps, pits and scratches;

[0054] S2. Sandblasting treatment: carry out self-inspection operation on the masked products in step S1 to confirm whether the masking is qualified, use 60# white corundum to sandblast the sprayed area, and use CDA to purge after sandblasting, not applicable The sandblasted area is completely masked with hot melt tape, and the interface of the tape is gentle. Sandblast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com