Low-pressure condensate waste heat recycling system of ethylene oxide/ethylene glycol device

A technology for recovery of ethylene oxide and waste heat, applied in steam separation devices, steam/steam condensers, indirect heat exchangers, etc., can solve problems such as waste of heat sources, reduce production costs, facilitate recycling, and save steam consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

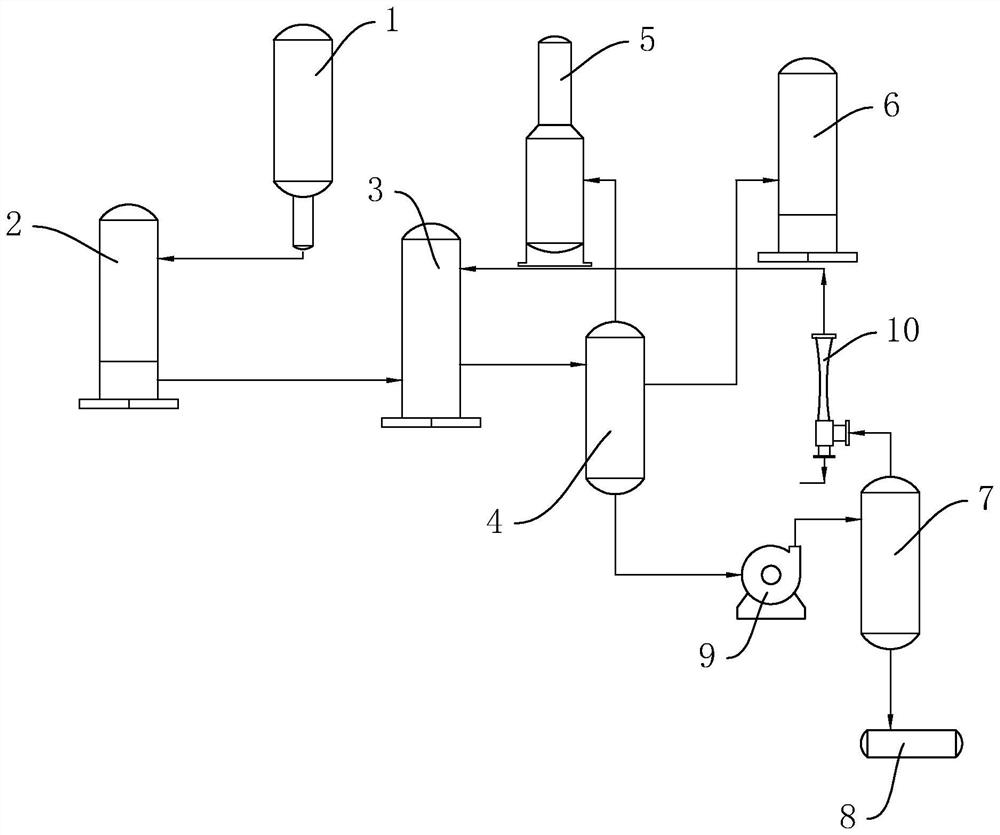

[0028] A low-pressure condensate waste heat recovery and utilization system of an ethylene oxide / ethylene glycol plant, refer to figure 1 , including the reactor 1, the washing tower 2 connected to the reactor 1, the stripping tower 3 connected to the washing tower 2, the first flash tank 4 connected to the stripping tower 3, the gas phase connected to the first flash tank 4 The carbon dioxide stripping tower 5 and regeneration tower 6 at the outlet, the second flash tank 7 connected to the liquid phase outlet of the first flash tank 4, the condensate tank 8 connected to the liquid phase outlet of the second flash tank 7, the second The gas phase outlet of the flash tank 7 is communicated with the stripping column 3 as stripping steam. A low-pressure condensate pump 9 is provided between the second flash tank 7 and the liquid phase outlet of the first flash tank 4 . An ejector 10 is provided between the gas phase outlet of the second flash tank 7 and the stripper 3 .

[0029...

Embodiment 2

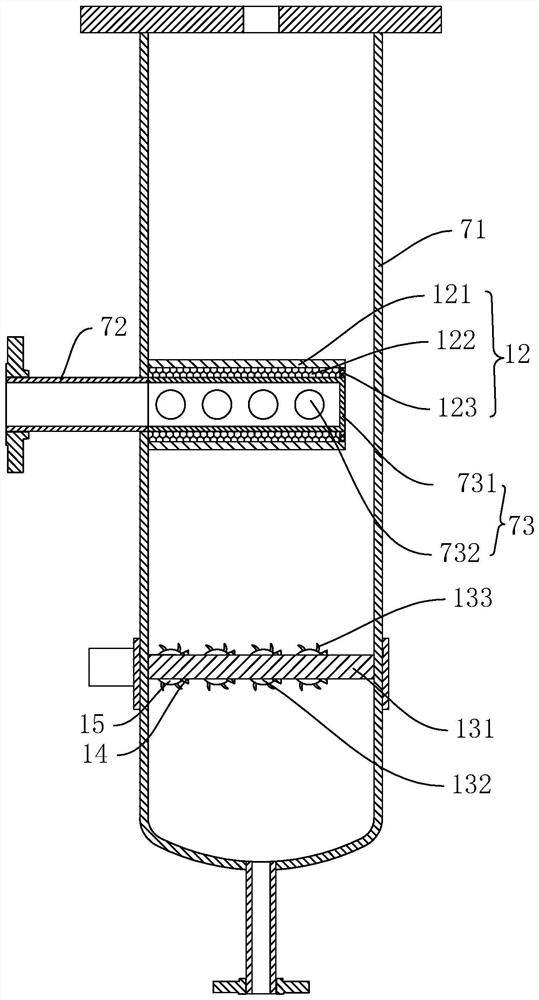

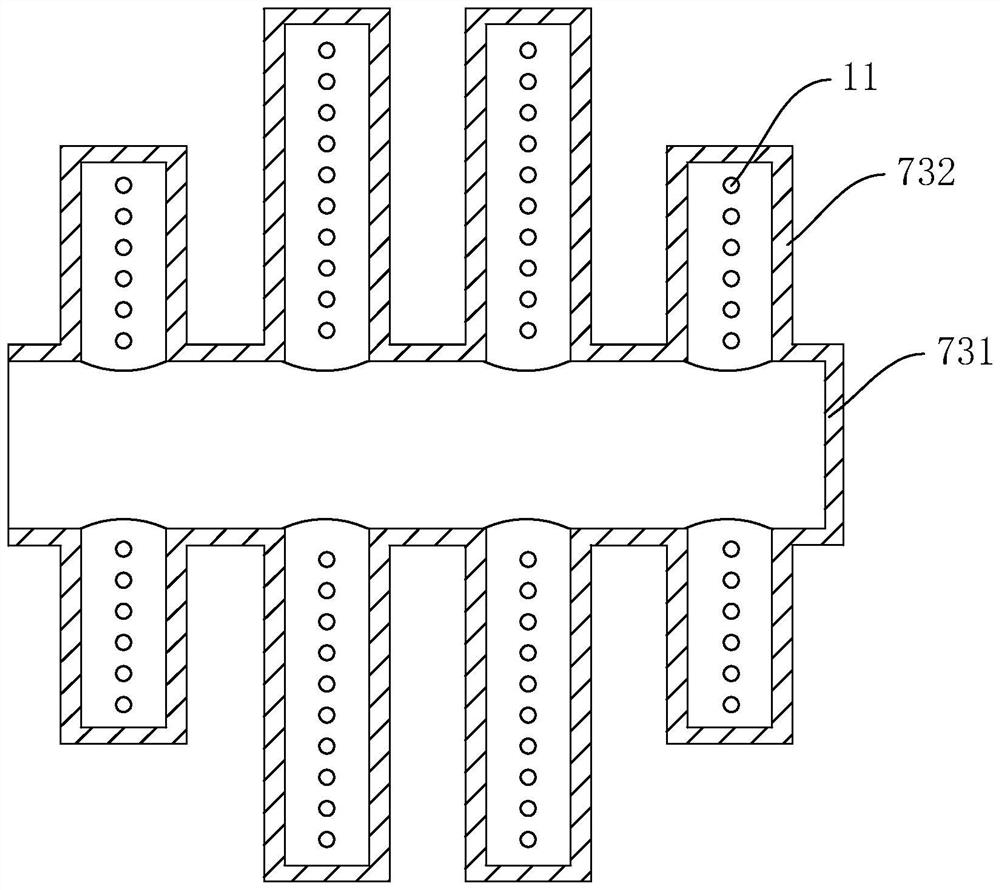

[0031] A low-pressure condensate waste heat recovery and utilization system of an ethylene oxide / ethylene glycol device is different from Example 1 in that with reference to figure 2 and image 3 The second flash tank 7 includes a tank 71 , an inlet channel 72 connected to the tank 71 and the liquid phase outlet of the first flash tank 4 , and a feeder 73 connected to the inlet channel 72 and disposed in the tank 71 . The gas phase outlet of the tank body 71 is opened at the top of the tank body 71, the gas phase outlet of the tank body 71 is connected with the ejector 10, the liquid phase outlet of the tank body 71 is opened at the bottom of the tank body 71, and the liquid phase outlet of the tank body 71 is connected to the ejector 10. The inlets of the condensate tank 8 are communicated with each other.

[0032] The inlet channel 72 is arranged on the side wall of the tank body 71, and the inlet channel 72 is communicated with the outlet of the low-pressure condensate pu...

Embodiment 3

[0037] A low-pressure condensate waste heat recovery and utilization system of an ethylene oxide / ethylene glycol plant, refer to Figure 4 , the difference from Embodiment 2 is that the branch pipe 732 includes a delivery pipe 7321 communicated with the main pipe 731 , a booster pipe 7322 communicated with the delivery pipe 7321 and higher than the header pipe 731 , and an injection pipe connected to the bottom of the booster pipe 7322 7323, an opening and closing member 16 is arranged between the injection pipe 7323 and the booster pipe 7322, the axial direction of the conveying pipe 7321 is perpendicular to the main pipe 731 and is horizontal, the axial direction of the booster pipe 7322 is vertical, and the height of the booster pipe 7322 It can be changed according to actual needs, the injection pipe 7323 is coaxial with the conveying pipe 7321, the opening and closing member 16 is a hydraulic water level control valve, the inlet of the hydraulic water level control valve i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com