Carbonate modified diatomite adsorbent as well as preparation method and application thereof

A diatomite and adsorbent technology, which is applied in the field of carbonate modified diatomite adsorbent and its preparation, can solve the problems that it is difficult to take into account the high adsorption capacity and the pH requirement of the effluent, and achieve the benefits of large-scale production, Effect of reducing waste liquid and fast adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

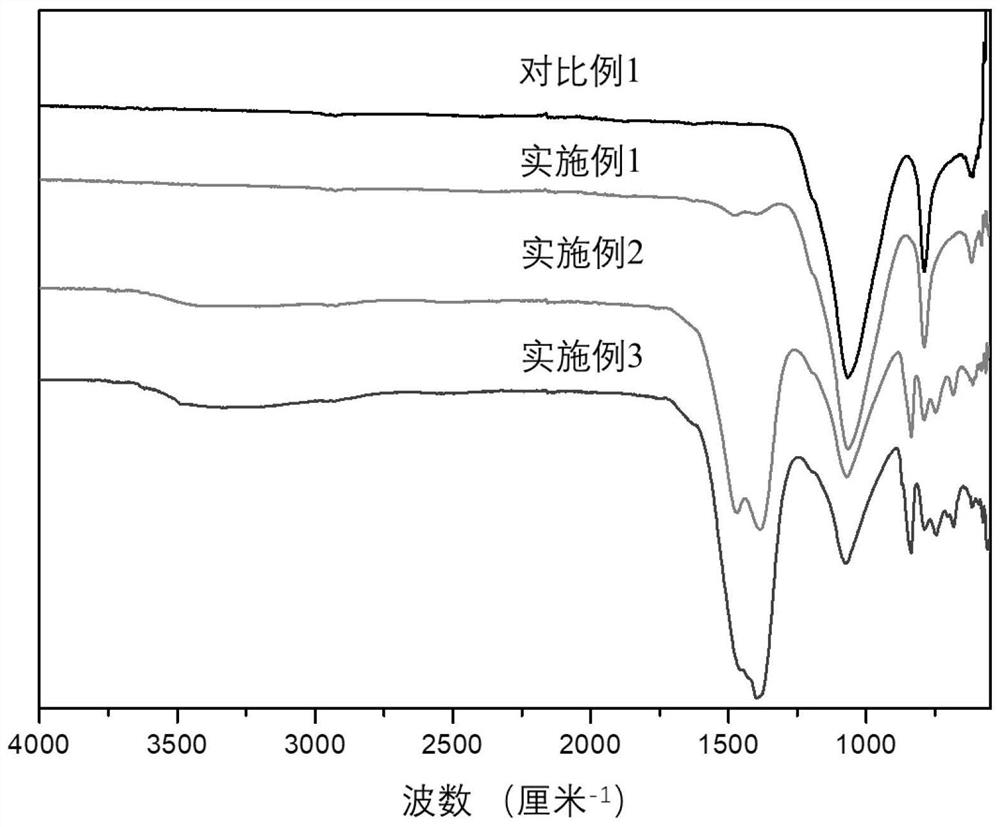

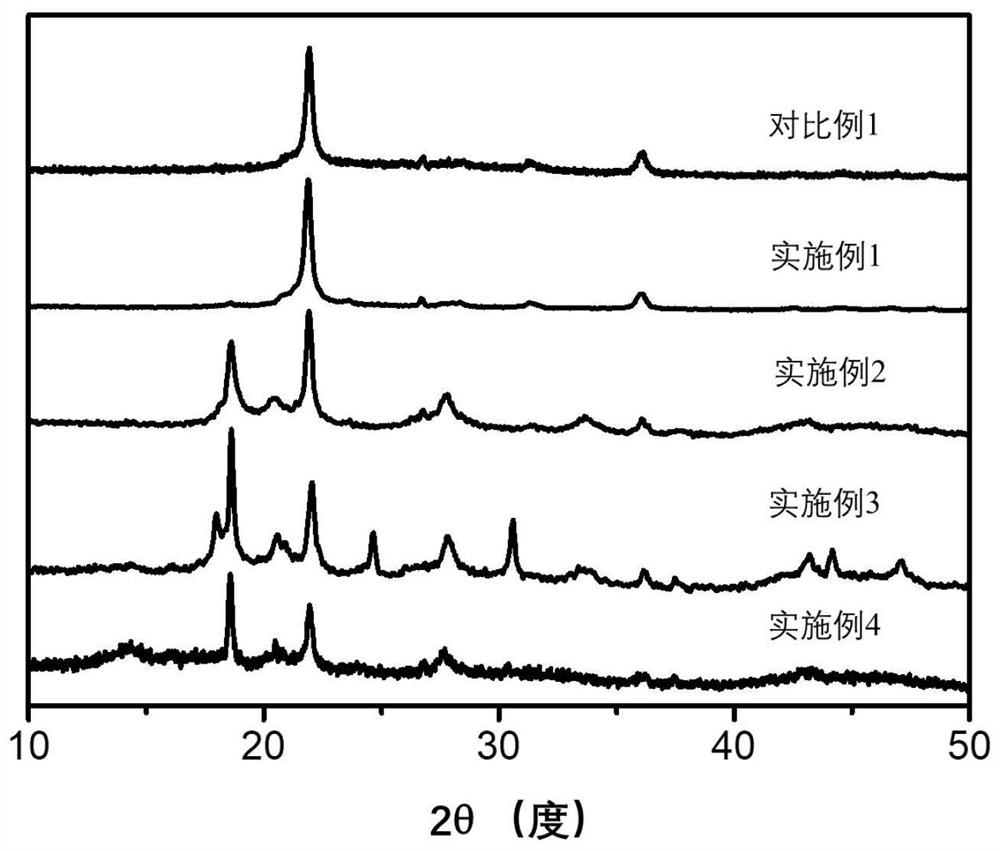

[0036] Embodiment 1. configure 3mol / L Na 2 CO 3 30 ml of the solution, 3 g of diatomaceous earth was added to the solution, and the mixture was stirred at room temperature for 3 hours. Prepare 0.1mol / L LaCl 3 solution 30ml, the LaCl 3 The solution was slowly added dropwise to the stirring diatomite solution, continued stirring at room temperature for 24 hours, and then stood for another 24 hours to fully precipitate lanthanum carbonate on the surface of the diatomite. The obtained solution was suction filtered and repeatedly rinsed with deionized water until the filtrate became neutral, and the filter cake was dried in a drying oven at 100° C. for 24 hours to obtain low-load lanthanum carbonate modified diatomite.

Embodiment 2

[0037] Embodiment 2. Configure 3mol / L Na 2 CO 3 30 ml of the solution, 3 g of diatomaceous earth was added to the solution, and the mixture was stirred at room temperature for 3 hours. Prepare 0.5mol / L LaCl 3 solution 30ml, the LaCl 3 The solution was slowly added dropwise to the stirring diatomite solution, continued stirring at room temperature for 24 hours, and then stood for another 24 hours to fully precipitate lanthanum carbonate on the surface of the diatomite. The obtained solution was suction filtered and repeatedly rinsed with deionized water until the filtrate was neutral, and the filter cake was dried in a drying oven at 100° C. for 24 hours to obtain a medium load of lanthanum carbonate modified diatomite.

Embodiment 3

[0038] Embodiment 3. Configure 3mol / L Na 2 CO 330 ml of the solution, 3 g of diatomaceous earth was added to the solution, and the mixture was stirred at room temperature for 3 hours. Prepare 1mol / L LaCl 3 solution 30ml, the LaCl 3 The solution was slowly added dropwise to the stirring diatomite solution, stirring was continued at room temperature for 24 hours, and then allowed to stand for another 24 hours to fully precipitate lanthanum carbonate on the surface of the diatomite. The obtained solution was suction filtered and repeatedly washed with deionized water until the filtrate was neutral, and the filter cake was dried in a drying oven at 100° C. for 24 hours to obtain high-loaded lanthanum carbonate-modified diatomite.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap