Novel raw hide chew manufacturing process

A technology of making crafts and hides, which is applied in the shaping or processing of animal feed, animal husbandry, animal feed, etc. It can solve the problems of teeth cleaning, flavor loss, and impermeability, so as to preserve the taste and aroma. Long-lasting effect, promotes uniform absorption, and improves penetration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

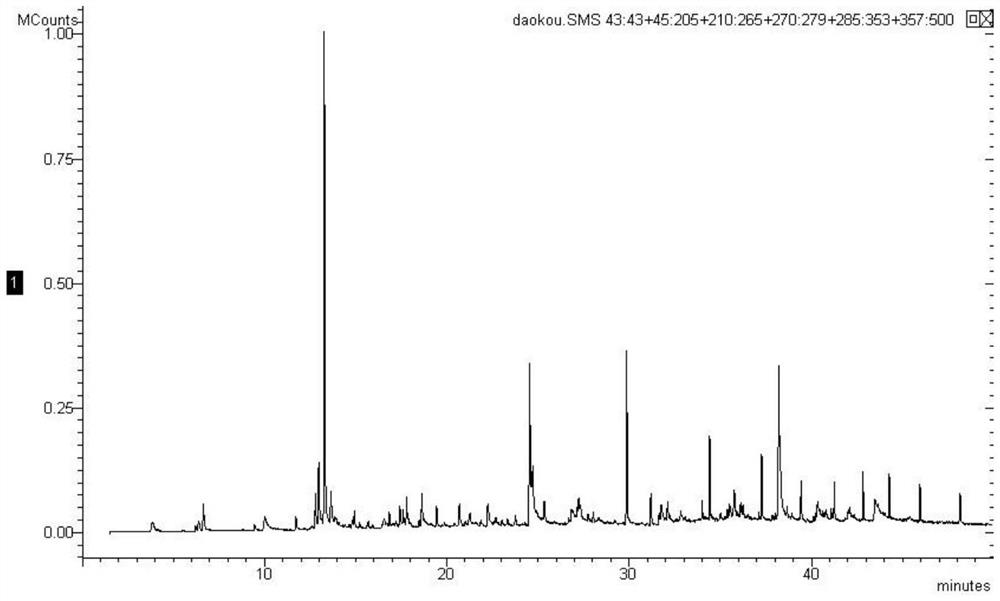

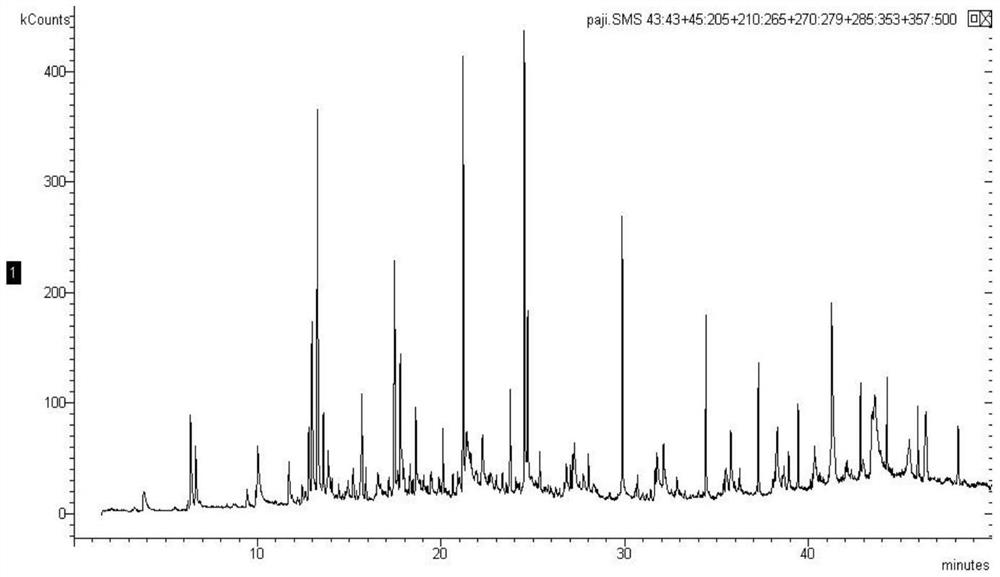

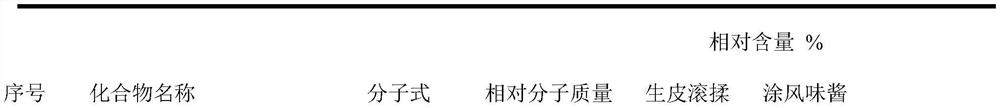

Image

Examples

Embodiment 1

[0026] Example 1: New-type rawhide chewing production process: degreasing and cleaning the raw bovine hide under the active state of the cells. After the rawhide is cleaned, the cells of the rawhide are still in an active state. The ratio of 3:1:6 is mixed thoroughly and marinated at room temperature for 12 hours, then put into a vacuum tumbler and tumbled for 4 hours, until the infiltrate fully penetrates into the rawhide tissue, and then removes the excess water on the surface, first when the cortex is still soft After drying or drying, it becomes a dry skin state, and then the finished product is made through the processes of cutting, softening, forming and drying.

Embodiment 2

[0027] Example 2: Novel rawhide chewing production process: degreasing and cleaning the raw bovine hides under the active state of the cells. After the rawhide is cleaned, the cells of the rawhide are still in an active state. :1:24 ratio, mix thoroughly and marinate at room temperature for 12 hours, put it in a vacuum tumbler, and tumble it for 4 hours, until the infiltrate fully penetrates into the rawhide tissue, and then remove the excess water on the surface, when the leather is still soft Make the corresponding chewing shape, enter the drying room to dry and make the finished product. The infiltrate was a mixture of crude fiber, vitamin A, vitamin B, vitamin E and chicken meal.

Embodiment 3

[0028] Example 3: New-type rawhide chewing production process: degreasing and washing the raw pig hides under the condition that the cells remain active, and after the rawhide is cleaned, the cells of the rawhide are still in an active state at this time. :1:30 ratio, mix thoroughly and marinate at room temperature for 24 hours, put it in a vacuum tumbler, and tumble it for 6 hours until the infiltrate fully penetrates into the rawhide cell tissue, and then removes excess water on the surface, while the leather is still soft Make the corresponding chewing shape, enter the drying room to dry and make the finished product. The infiltrate is a mixture of flavorants, flavor additives, taste enhancers, animal liver extract and chicken meal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com