Steam heat pump for heat fluid regenerative flash evaporation circulation

A thermal fluid and flash evaporation technology, applied in heat pumps, superheaters, lighting and heating equipment, etc., can solve the problems of difficult energy saving, technical economy, loss of decompression potential energy, etc., to avoid investment and power consumption, reduce operating costs, The effect of reducing the initial investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

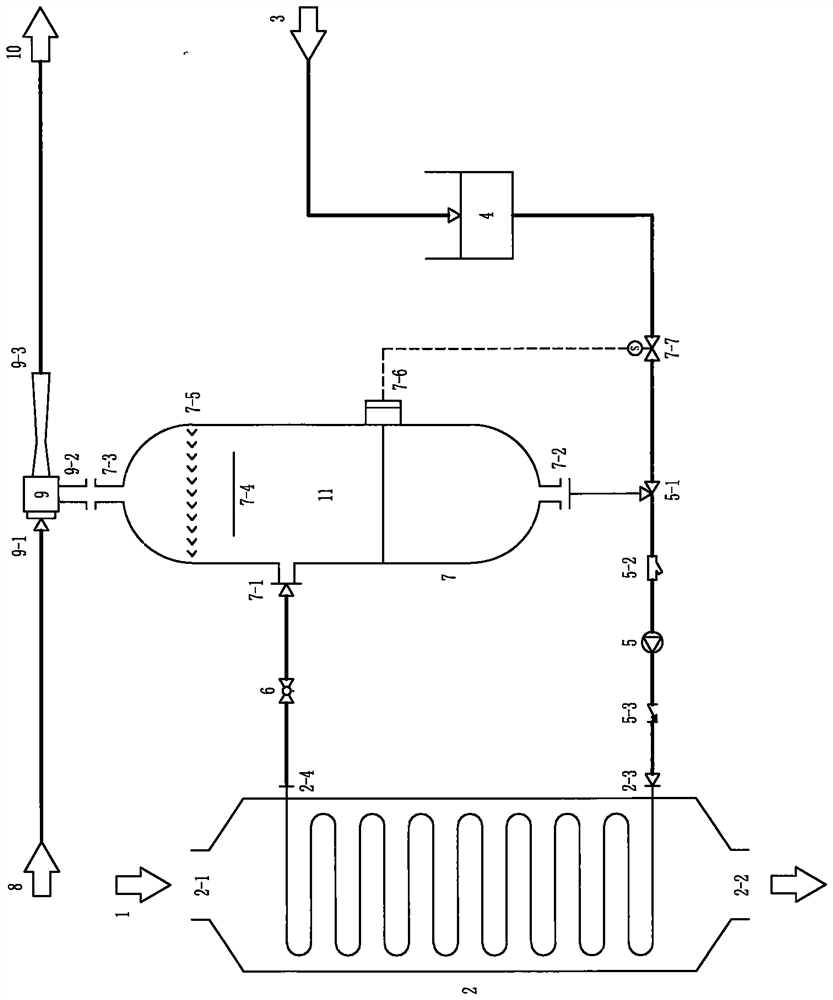

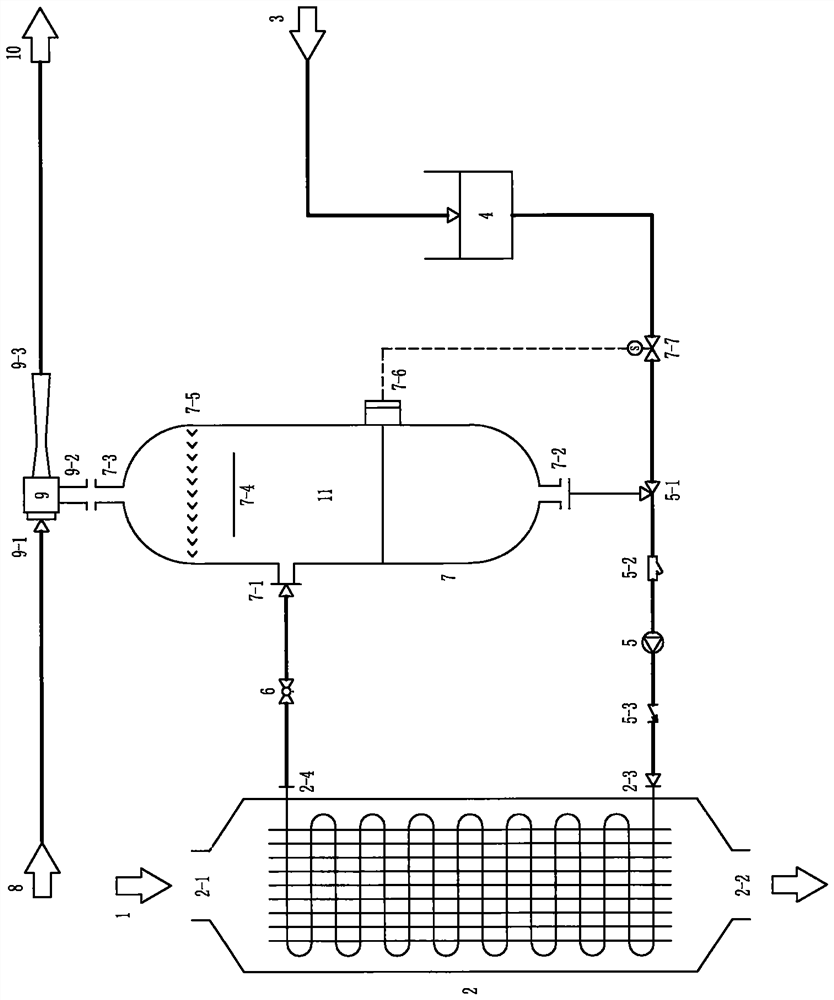

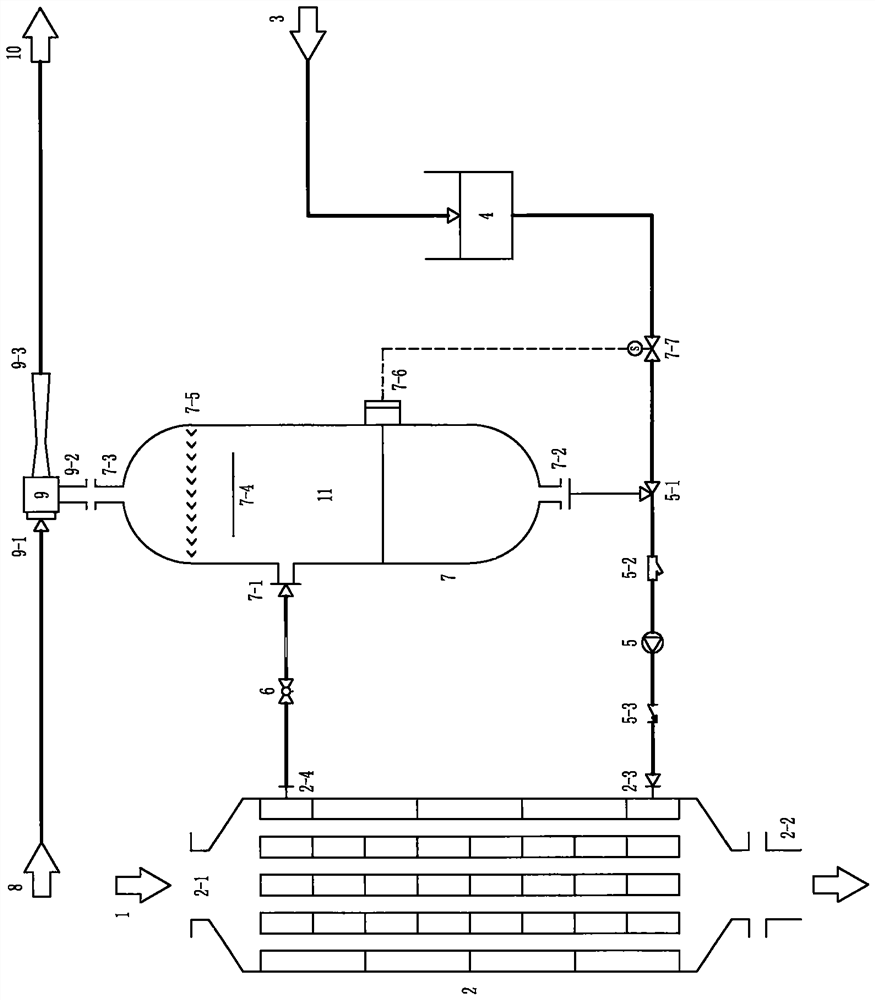

[0027] The example of the hot fluid regenerative flash cycle steam heat pump proposed by the present invention is attached image 3It is described as follows: it consists of a papermaking black lye 1 with an average flow of 418t / h and a temperature of 117 / 105°C; a shell-and-tube thermal fluid regenerator 2 with a heat output of 5.824MW; a 304 stainless steel thermal fluid inlet with a diameter of 400mm 2-1; 304 stainless steel thermal fluid outlet 2-2 with a diameter of 400mm; softened water inlet 2-3 of a carbon steel regenerator with a diameter of 400mm; softened water outlet of a carbon steel regenerator with a diameter of 400mm 2-4; average flow rate 418t / h and demineralized water 3 at a temperature of 112 / 100°C; volume 3m 3 / Carbon steel softening water tank 4 with wall thickness of 5mm; circulating water pump 5 with flow rate of 418t / h, lift of 7mH20 and electric power of 10.29kW; interface diameter of 400mm / length of 800mm / wall thickness of 3mm carbon steel water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com