High-dispersity carbon nanotube, preparation method thereof and secondary battery

A technology of carbon nanotubes and high dispersibility, which is applied in the field of carbon nanotubes with high dispersibility and its preparation, can solve the problems of poor dispersibility and stability of carbon nanotubes, high cost, unfriendly environment, etc., and achieves excellent electrical conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

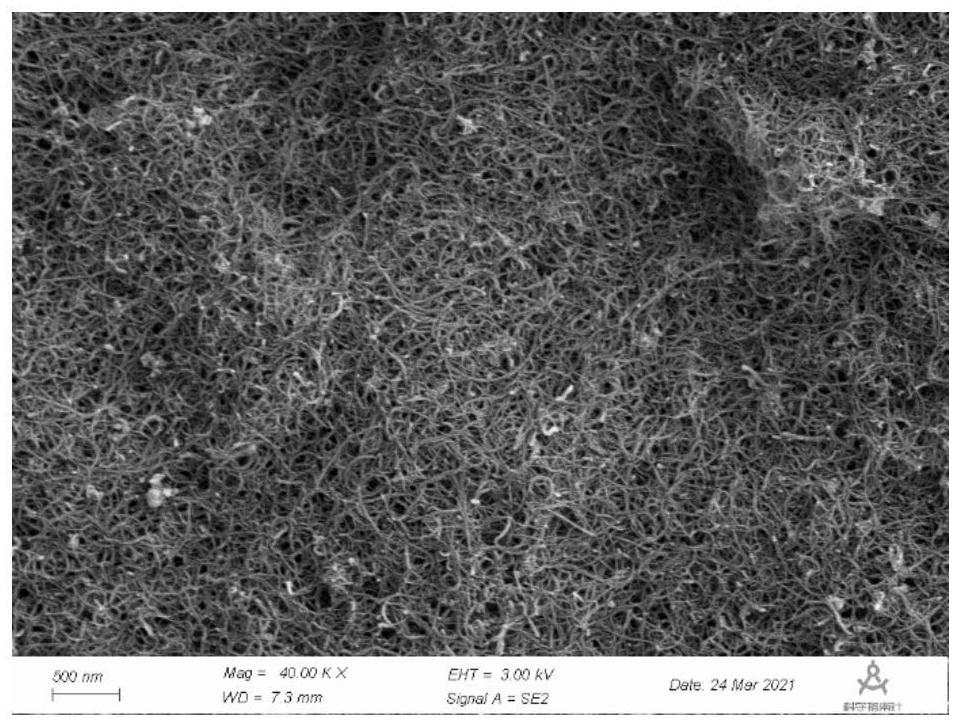

[0091] Weigh 1g of single-walled carbon nanotubes, 30g of multi-walled carbon nanotubes, 2g of polyvinylpyrrolidone, 1g of cetyltrimethylammonium bromide and 495g of deionized water, and then place the above components in Mix well in a beaker to form a premix slurry. Then, the premixed slurry was poured into the feed cup of the high-pressure homogenizer, and the slurry was homogenized and dispersed at a pressure of 800 bar. The particle size of the slurry was D50<20 μm. The slurry was spray-dried at a feed temperature of 210°C and a discharge temperature of 130°C to obtain black powder. The powder was placed in a tube furnace, and nitrogen was passed through. The heating rate of the tube furnace was controlled at 10°C / min, the temperature was raised to 500°C, and the temperature was lowered to normal temperature after holding for 6 hours. The inert gas was stopped, and the black powder was taken out. Carbon nanotubes with high dispersibility are obtained.

Embodiment 2

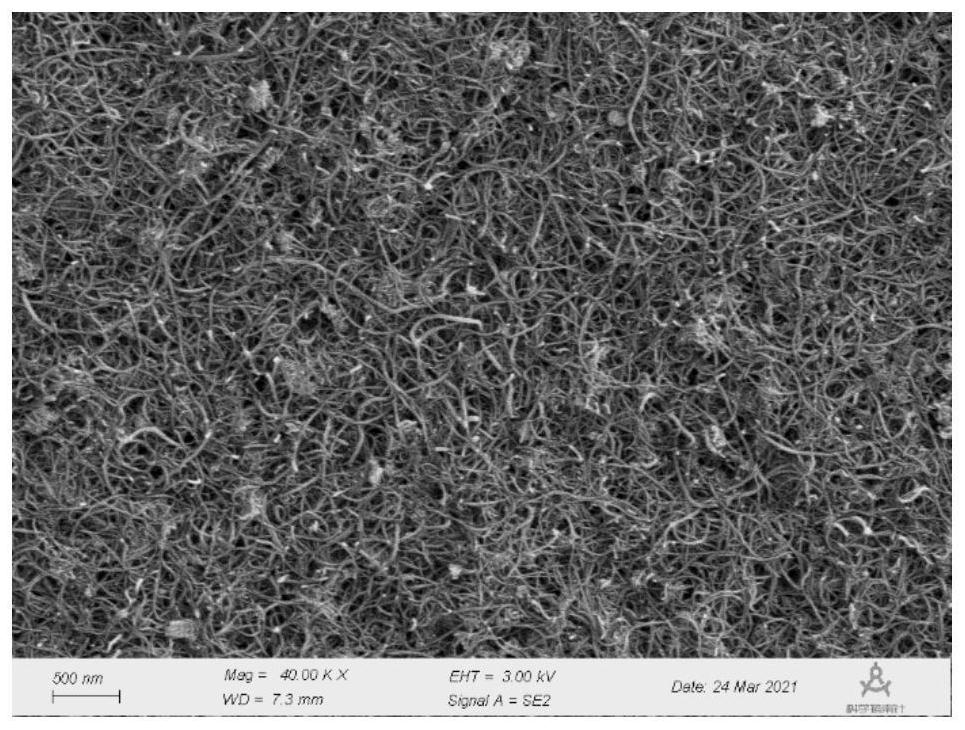

[0093] Weigh 1g of single-walled carbon nanotubes, 50g of multi-walled carbon nanotubes, 1g of polyvinylpyrrolidone, 3g of octadecyltrimethylammonium chloride and 479g of deionized water, and then place the above components in Mix well in a beaker to form a premix slurry. Then, the premixed slurry was poured into the feed cup of the high-pressure homogenizer, and the slurry was homogenized and dispersed at a pressure of 800 bar. The particle size of the slurry was D50<20 μm. The slurry was spray-dried at a feed temperature of 210°C and a discharge temperature of 130°C to obtain black powder. The powder was placed in a tube furnace, passed nitrogen, the heating rate of the tube furnace was controlled at 10°C / min, the temperature was raised to 600°C, and the temperature was lowered to normal temperature after holding for 8 hours, the inert gas was stopped, and the black powder was taken out. Carbon nanotubes with high dispersibility are obtained.

Embodiment 3

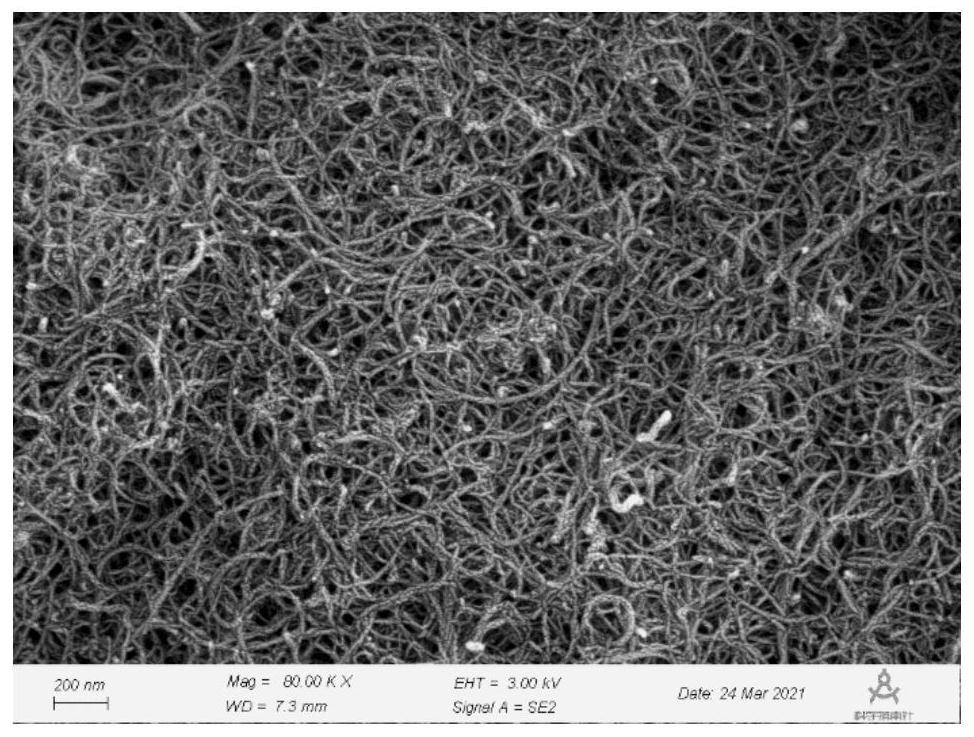

[0095] Weigh 1 g of single-walled carbon nanotubes, 40 g of multi-walled carbon nanotubes, 4 g of polyvinyl alcohol, 3 g of cetyltrimethylammonium chloride and 473 g of deionized water, and then place the above components in a Mix well in a beaker to form a premix slurry. Then, the premixed slurry was poured into the feed cup of the high-pressure homogenizer, and the slurry was homogenized and dispersed at a pressure of 800 bar. The particle size of the slurry was D50<20 μm. The slurry was spray-dried at a feed temperature of 210°C and a discharge temperature of 130°C to obtain black powder. The powder was placed in a tube furnace, and nitrogen was passed through. The heating rate of the tube furnace was controlled at 10°C / min, the temperature was raised to 500°C, and the temperature was lowered to normal temperature after holding for 7 hours. The inert gas was stopped, and the black powder was taken out. Carbon nanotubes with high dispersibility are obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com