Preparation method of mesoporous reduced graphene oxide absorbent

A graphene and absorbent technology, which is applied in the field of preparation of mesoporous reduced graphene oxide absorbents, can solve the problems of increasing washing, freeze-drying cycles, large amount of graphene, and limited wave-absorbing performance, and achieves remarkable mesoporous characteristics. , the effect of large specific surface area and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present embodiment discloses a preparation method of a mesoporous reduced graphene oxide absorbent, comprising the following steps:

[0038] Step 1: Prepare a certain concentration of reducing agent aqueous solution, the reducing agent aqueous solution can be ascorbic acid aqueous solution or hydroiodic acid aqueous solution, and the ascorbic acid aqueous solution concentration range is 2~12mg mL -1 , the concentration range of hydroiodic acid aqueous solution is 5.7wt%~57wt%;

[0039] Step 2: Weigh a certain quality of graphene oxide powder and add it to the reducing agent water solvent, and add 0.5g graphene oxide powder to every 50mL of the reducing agent aqueous solution;

[0040] Step 3: put the solution in step 2 into a blast drying oven for heating, the heating temperature is 65~105°C, and the heating time is 2~4h;

[0041] Step 4: After heating, the product is washed with deionized water to remove excess reducing agent, and the product is centrifugally wash...

Embodiment 1

[0044] The present embodiment provides a mesoporous reduced graphene oxide absorbent, and the preparation method thereof includes the following steps:

[0045] Step 1: Prepare 50mL with a concentration of 4mg mL -1 Aqueous solution of ascorbic acid reducing agent;

[0046] Step 2: add 0.5g graphene oxide powder to the ascorbic acid aqueous solution;

[0047] Step 3: Put the solution of Step 2 into an oven and heat at 95°C for 2h;

[0048] Step 4: use deionized water to perform centrifugal washing on the obtained product, and the washing times are 2 times;

[0049]Step 5: freeze-dry the product after centrifugal washing at -50° C. for 24 hours, and grind the freeze-dried bulk product to finally obtain mesoporous reduced graphene oxide powder.

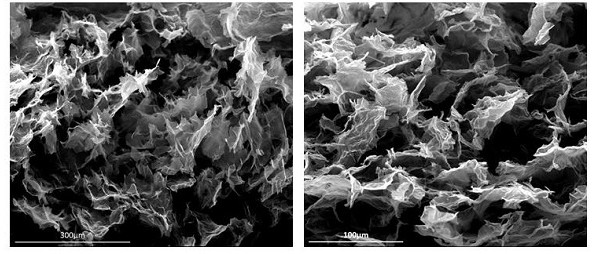

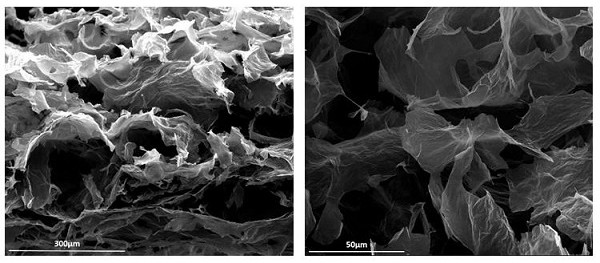

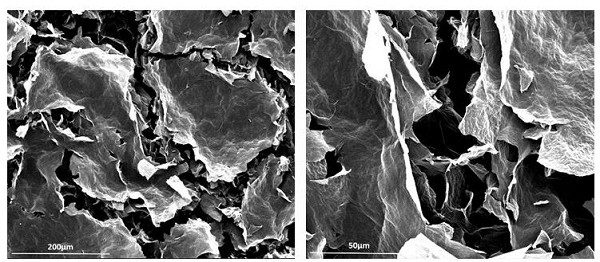

[0050] figure 1 This is a scanning electron microscope picture of the mesoporous reduced graphene oxide powder obtained in Example 1 of the present invention, from which it can be seen that the surface of the lamella structure presen...

Embodiment 2

[0052] The difference between this example and Example 1 is that the concentration of the prepared ascorbic acid aqueous solution is 12 mg mL -1 , and the remaining steps are the same as in Example 1 to obtain mesoporous reduced graphene oxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com