Method for synthesizing 5-hydroxymethylfurfural by catalyzing glucose conversion

A technology for the conversion of hydroxymethylfurfural and glucose, applied in chemical instruments and methods, molecular sieve catalysts, physical/chemical process catalysts, etc., can solve the problems of insufficient conversion of glucose and low efficiency of biomass development and utilization, and achieve high industrial production Application value, improvement of resource utilization efficiency, and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

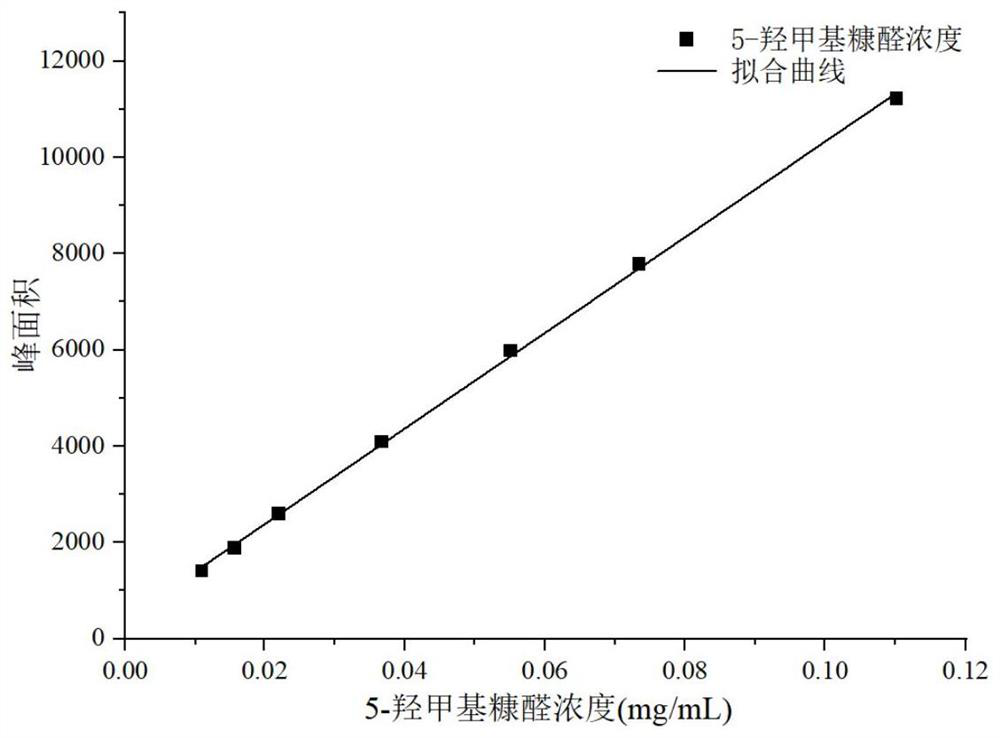

[0044] The embodiment of the present application discloses a method for catalyzing the conversion of glucose to synthesize 5-hydroxymethylfurfural, comprising the following specific steps:

[0045] (1) A thick-walled pressure-resistant bottle made of high borosilicate glass was used as a reaction vessel, and 100 mg of glucose, 30 mg of H-β molecular sieve, 200 mg of NaCl, 4 mL of tetrahydrofuran and 1 mL of deionized water were added to the thick-walled pressure-resistant bottle, wherein , SiO of H-β molecular sieve 2 with Al 2 O 3 The ratio is 30; the outer diameter of the thick-wall pressure bottle is 36mm, the height is 70mm, and the capacity is 15mL. The thick-wall pressure bottle has the advantages of good heat transfer effect and uniform heat conduction.

[0046] After adding the rotor to the thick-walled pressure-resistant bottle, put the thick-walled pressure-resistant bottle into an oil bath pot with a magnetic stirrer to stir, the temperature of the oil bath pot is...

Embodiment 2

[0052] The difference between this application and Example 1 is: the SiO of H-β molecular sieve 2 with Al 2 O 3 The ratio is 25.

Embodiment 3

[0058] The difference between the present application and Example 1 is that the amount of glucose added is 80 mg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com