Preparation method of cold extraction instant tea and special freezing equipment

A technology of freezing equipment and instant tea, which is applied in tea extraction and pre-extraction tea treatment, etc. It can solve the problems of bitter taste, dark color and low aroma, and achieve the effect of good flavor, pure aroma, and enhanced flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

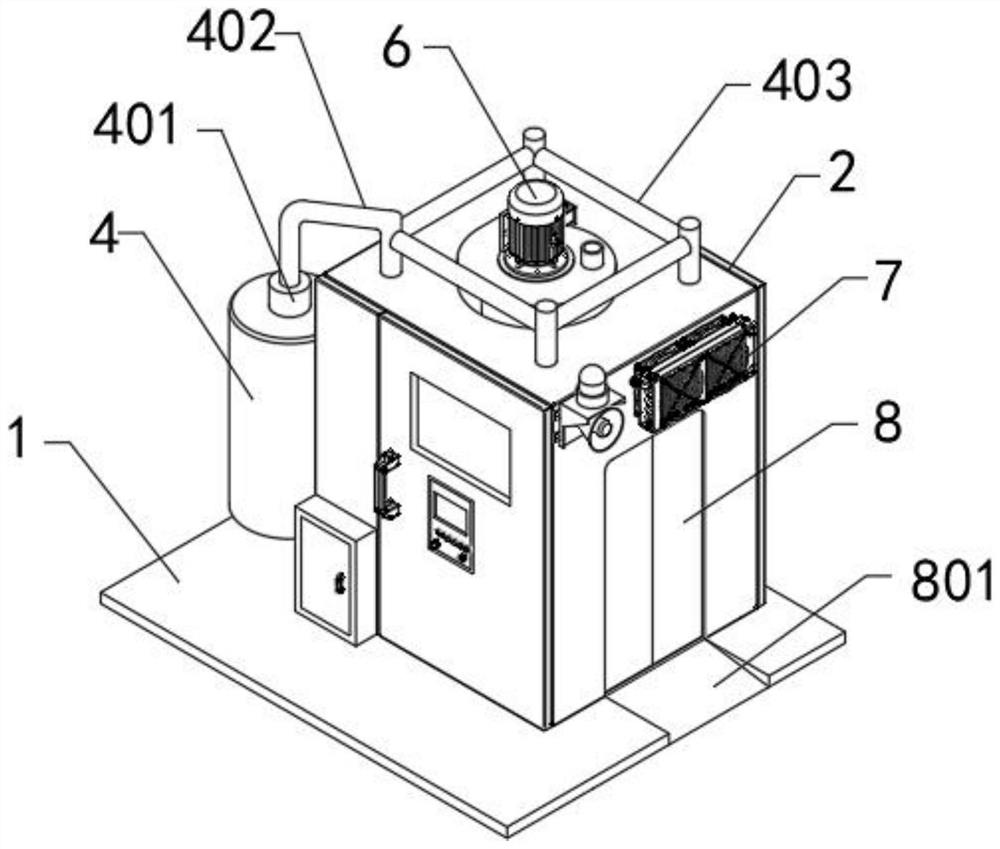

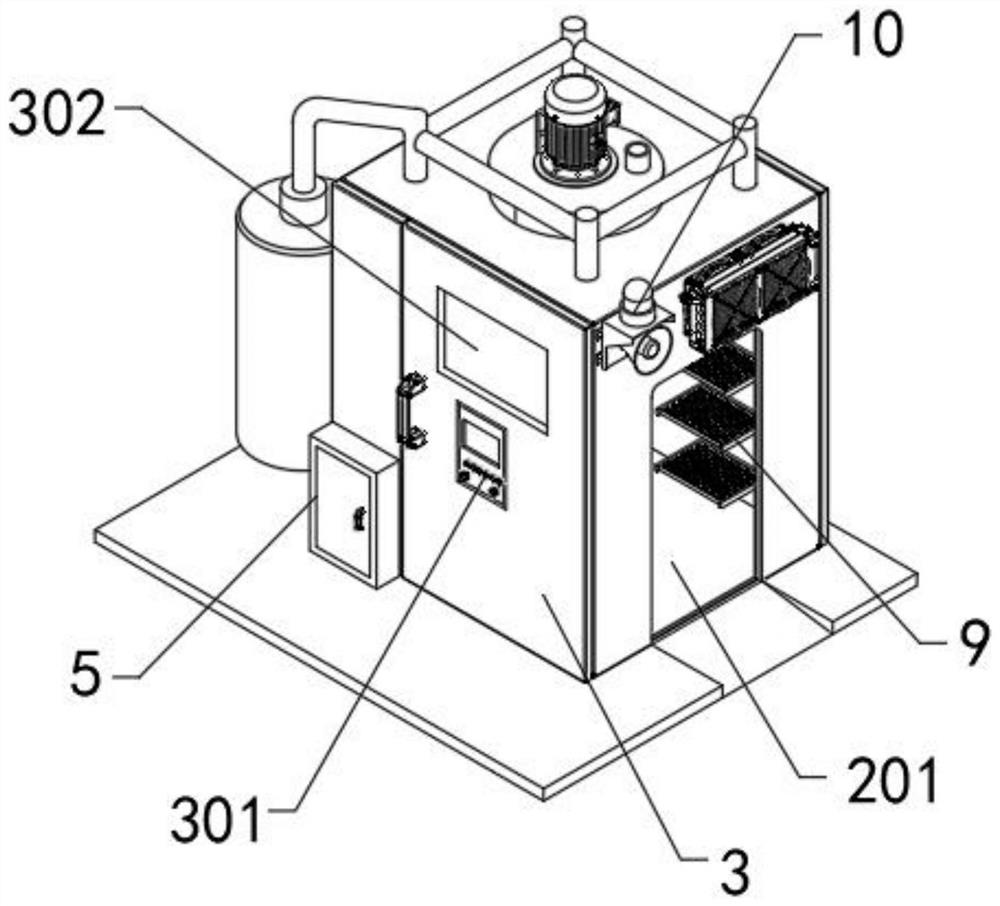

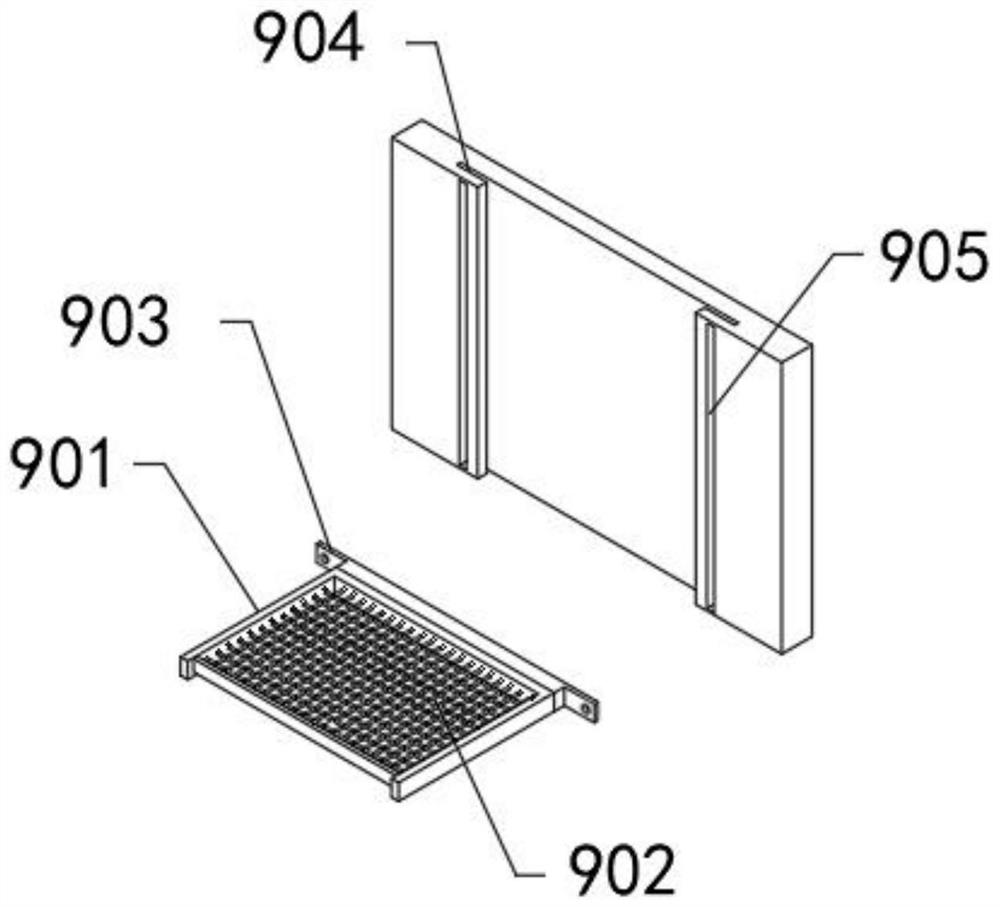

[0034] This embodiment provides a technical solution: a rapid freezing device for cold-extracted instant tea, see Figures 1 to 3 , including a base 1, the top of the base 1 is provided with a freezer compartment 2, the freezer compartment 2 is provided with a temperature sensor, a humidity sensor and an air pressure sensor, and the side wall of the base 1 is provided with a personnel entry and exit operation door 3. A control electrical cabinet 5 is arranged on the side of the personnel entering and exiting the operation door 3. The top of the base 1 and the side wall of the side adjacent to the control electrical cabinet 5 are provided with a liquid connecting with the interior of the freezer compartment 2. Nitrogen tank 4, the side wall of the other side adjacent to the freezing chamber 2 and the control cabinet 5 is provided with an electronically controlled switch door tea liquid inlet and outlet 201, and a refrigerator 7 is provided at the top of the tea liquid inlet and ...

Embodiment 2

[0043] The present embodiment provides a processing method of cold-extracted instant tea, and the specific operations are as follows:

[0044] (1) For the baking of raw materials, select fresh tea leaves with fresh color, high aroma and pure taste, first place them in a dryer for baking, bake at 120-180°C for 10-30 minutes, and then cool to room temperature.

[0045] (2) Infiltration with water: put the tea leaves obtained in step (1) into a percolation column, add deionized water with 1 to 10 times the quality of the tea leaves, and control the water temperature to be between 0 and 45°C.

[0046] (3) percolation: pass deionized water at 0 to 45° C. of 1 to 5 times the quality of tea leaves into the percolation column of step (2), collect the feed liquid at the percolation outlet, and control the temperature of the feed liquid from 0 to 45 ℃; then pass the feed liquid into the percolation column, and carry out circulatory percolation for 60-180 minutes.

[0047] (4) Filtratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com