Application of polyethylene glycol hydrogel in preparation of self-adhesive biomedical material

A biomedical material, polyethylene glycol technology, applied in the application field of polyethylene glycol hydrogel in the preparation of self-adhesive biomedical materials, can solve the problems of toxic and side effects, inconvenient use, etc., and achieve high safety , easy to use and convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

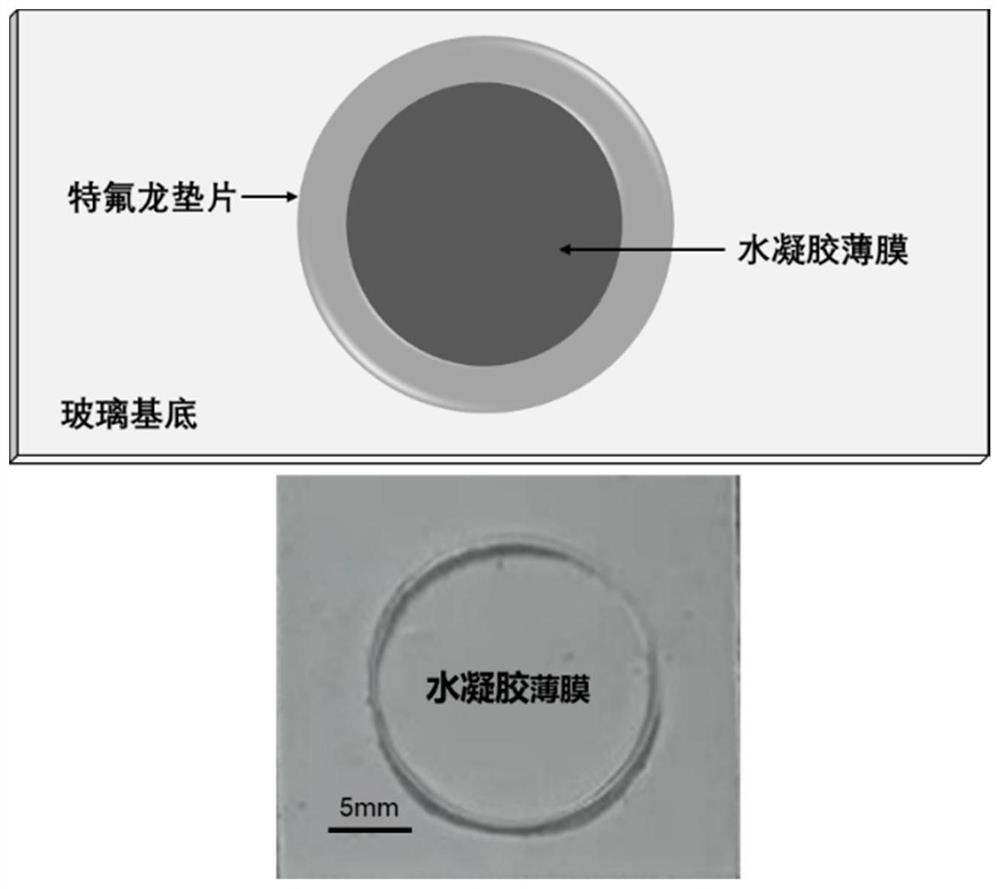

[0032] Example 1 Preparation of the self-adhesive polyethylene glycol hydrogel film of the present invention

[0033] Dissolve 400 mg of ester-bonded benzaldehyde group-terminated 8-arm polyethylene glycol (molecular weight 20 kDa) in 2 mL of 0.1 M phosphate buffer solution (pH 7.4) as solution A; A phosphate buffer solution with a base amino ratio of 1:1) was used as the B solution; a tetrafluoro ring (inner diameter 1.5cm) and a glass slide were used to make a mold, and the A and B solutions were mixed in equal volumes and then placed in a centrifuge tube using a vortex. Mix well with a rotary shaker, quickly pipette 125 μl of the mixture dropwise to the center of the Teflon circle, and make the droplet spread on the surface of the glass slide. After waiting for 10 minutes, the cured gel is removed to form a hydrogel film (such as figure 1 shown).

Embodiment 2

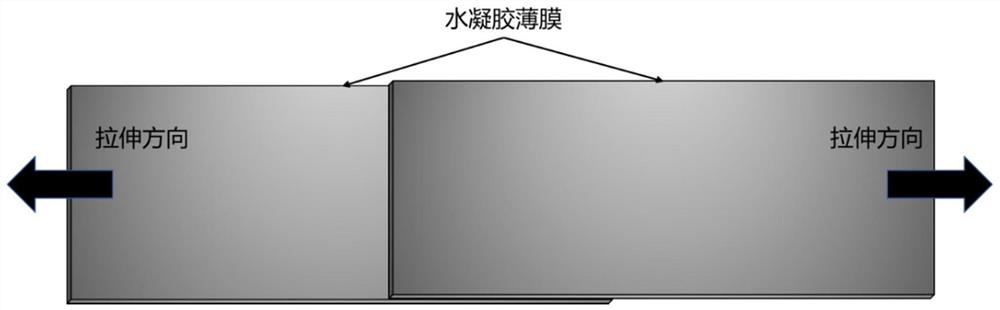

[0034] Example 2 Adhesion test between self-adhesive polyethylene glycol hydrogel films of the present invention

[0035] Dissolve 400 mg of ester-linked benzaldehyde group-terminated 8-arm polyethylene glycol (molecular weight 20 kDa) in 2 mL of 0.1 M phosphate buffer solution (pH 7.4) as solution A; The phosphate buffer solution with amino molar ratio of 2:1, 1:1, 1:1.5 and 1:2) was used as the B solution; the mold was made by using a tetrafluoro mold (2cm×1cm) and a glass slide, and the A After mixing equal volumes of solution B and solution B, mix thoroughly with a vortex shaker in a centrifuge tube, and quickly pipette 125 μl of the mixture dropwise into the center of the Teflon circle, so that the droplets are spread on the surface of the glass slide. After waiting for 10 minutes, the cured gel is removed to form a hydrogel film. Two pieces of hydrogel film (2cm×1cm) were figure 2 Mode stacking (overlapping area 1cm×1cm) Place a 200g weight on the stacking site for 5 ...

Embodiment 3

[0039] Example 3 Adhesion test of polyethylene glycol hydrogel films based on different polyamino polymers

[0040] Dissolve 400 mg of ester-linked benzaldehyde group-terminated 8-arm polyethylene glycol (molecular weight 20 kDa) in 2 mL of 0.1 M phosphate buffer solution (pH 7.4) as solution A; configure polylysine or polyethylene The phosphate buffer solution of imine solution (the molar ratio of aldehyde groups to amino groups is 2:1, 1:1) is used as solution B; the mold is made by using a tetrafluoro mold (2cm×1cm) and a glass slide, and solutions A and B are After equal volume mixing, fully mix with a vortex shaker in a centrifuge tube, and quickly pipette 125 μl of the mixture dropwise to the center of the Teflon circle, so that the droplets are spread on the surface of the glass slide. After waiting for 10 minutes, the cured gel is removed to form a hydrogel film. Two pieces of hydrogel film (2cm×1cm) were figure 2 Mode stacking (overlapping area 1cm×1cm) Place a 200...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com