Micro-droplet capture microfluidic structure, chip with micro-droplet capture microfluidic structure and capture/release method

A microfluidic chip, microdroplet technology, applied in chemical instruments and methods, laboratory utensils, laboratory containers, etc., can solve the problem of unfavorable droplet sorting and recovery, difficult droplet release, chip geometry Complexity and other problems, to achieve the effect of micro-droplet capture, reduced difficulty, and high-throughput micro-droplet capture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

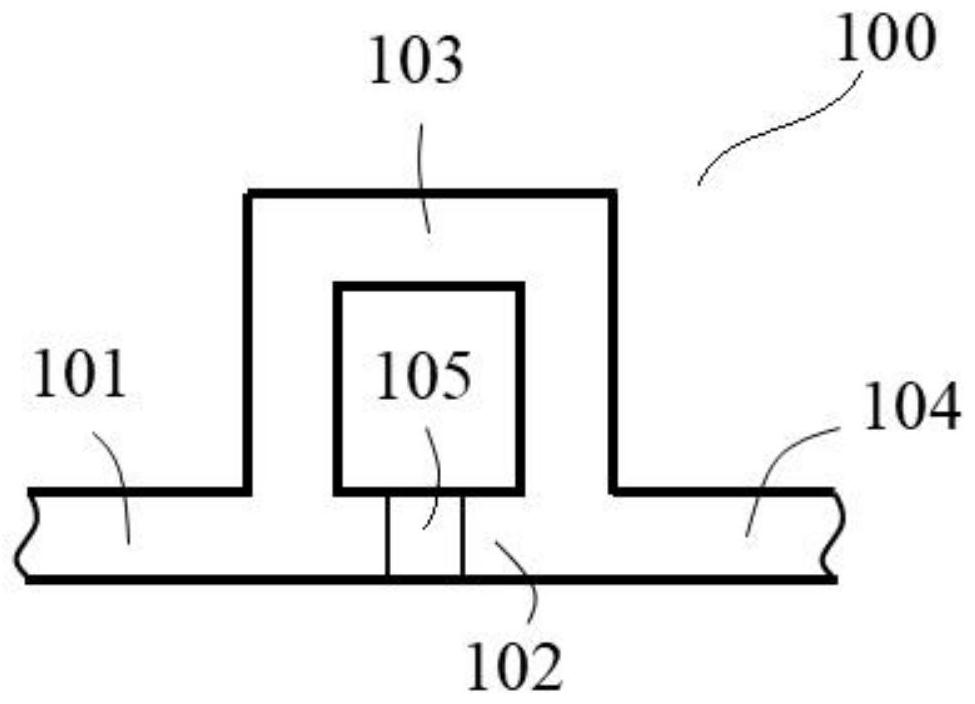

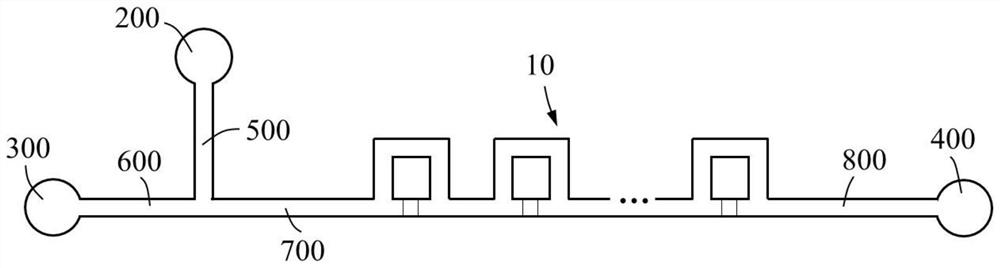

[0038] see attached figure 1 , the embodiment of the present invention discloses a micro-droplet capture microfluidic structure, including a micro-droplet capture unit 10, a droplet capture area 105 is set on the microchannel of the micro-droplet capture unit 10, and the droplet capture area 105 is set Media layer that captures microdroplets.

[0039] The microchannel includes a microchannel unit 100. The microchannel unit 100 includes a first flow channel 102 and a second flow channel 103. Both ends of the first flow channel 102 are an inlet channel 101 and an outlet channel 104. The second flow channel 103 is connected in parallel with the first flow channel 102. Between the inlet channel 101 and the outlet channel 104 ; the medium layer is arranged in the first flow channel 102 between the inlet channel 101 and the outlet channel 104 .

Embodiment 2

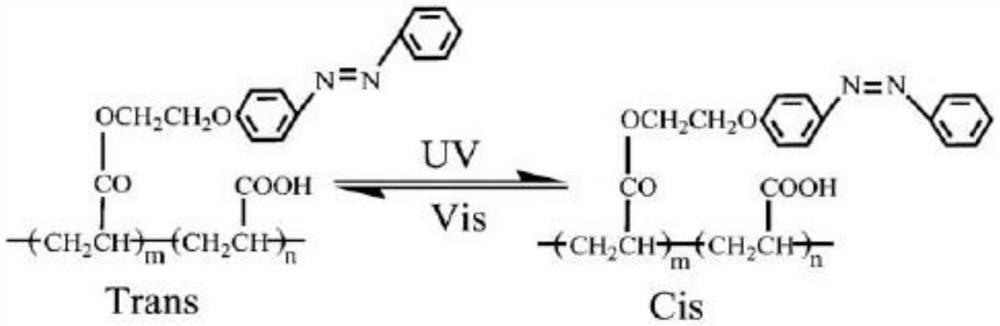

[0041] On the basis of Example 1, the microdroplets are water-in-oil microdroplets, the medium layer has a hydrophilic surface, and the microchannels have a hydrophobic material layer or are made of a hydrophobic material.

[0042] In order to further optimize the above technical solution, the material of the hydrophilic surface is glass, and the layer of hydrophobic material or the hydrophobic material is PDMS.

Embodiment 3

[0044] On the basis of Example 1, the microdroplets are oil-in-water microdroplets, the medium layer has a hydrophobic surface, and the microchannels have a hydrophilic material layer or are made of a hydrophilic material.

[0045] In order to further optimize the above technical solution, the material of the hydrophobic surface is PDMS, and the hydrophilic material layer or the hydrophilic material is glass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com