Polishing device for photovoltaic sheet machining

A chip processing and photovoltaic technology, applied to machine tools, metal processing equipment, grinding machines, etc., which are suitable for grinding workpiece planes, can solve the problems of inconvenient removal of alignment structures, lack of processing functions, unfavorable and efficient automatic grinding, etc., to achieve The effect of automatic reciprocating grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

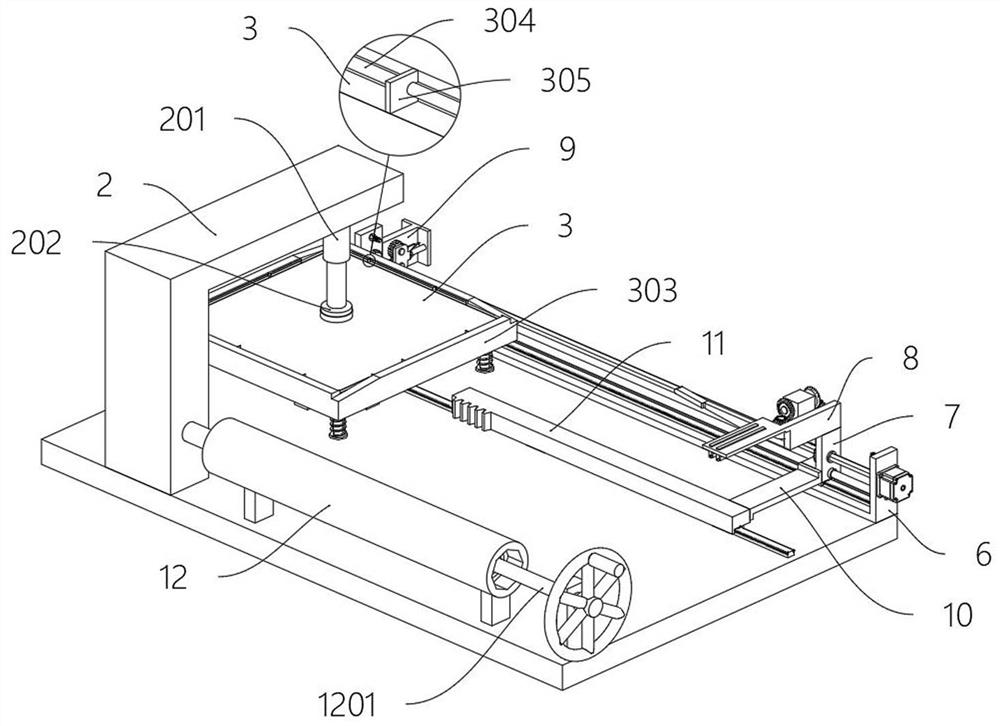

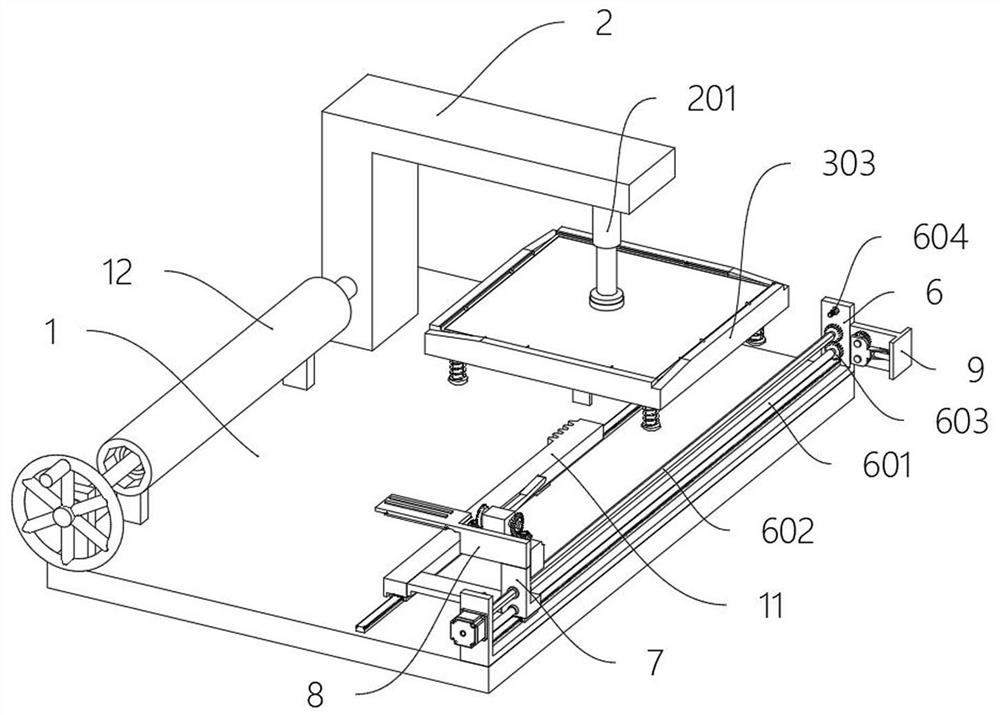

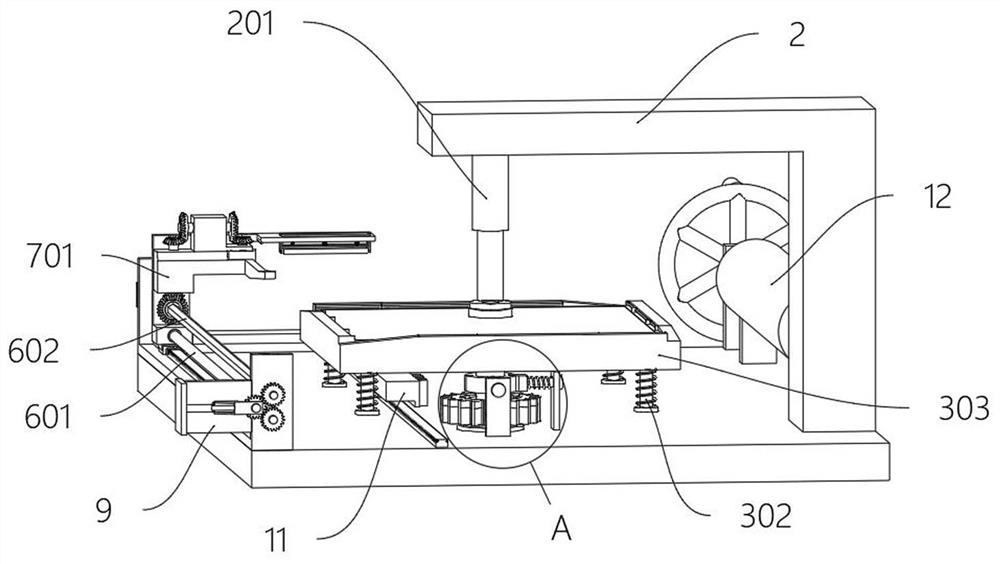

[0035] Example: please refer to Figure 1 to Figure 10 :

[0036] The present invention provides a polishing device for photovoltaic sheet processing, comprising: a base 1, the top of which is a flat plate structure; an L-shaped frame 2, which is fixedly arranged on one side of the top of the base 1, and the L-shaped frame A telescopic gas rod 201 is fixedly arranged at the bottom of the front end of 2, and the L-shaped frame 2 also includes: a rotating rubber block 202, the bottom end of the telescopic gas rod 201 is rotatably provided with a rotating rubber block 202 with a bearing; An intermediate shaft 301 is fixedly arranged in the middle of the bottom, and the bottom of the intermediate shaft 301 is rotatably arranged on the top of the base 1 with the tapered roller bearing, and the intermediate shaft 301 is aligned with the center of the telescopic gas rod 201; the outer side of the intermediate shaft 301 is fixedly provided with an inner ratchet gear 5; a connecting r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com