Clay stabilizer and preparation method thereof

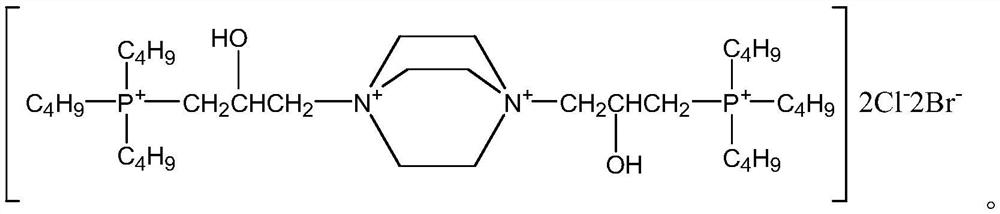

A technology of clay stabilizer and triethylenediamine, which is applied in the field of clay stabilizer and its preparation, clay stabilizer for water injection and its preparation, can solve the problems of affecting anti-swelling effect and limited adsorption effect, and achieve reservoir adaptability Strong, high anti-expansion rate, the effect of less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

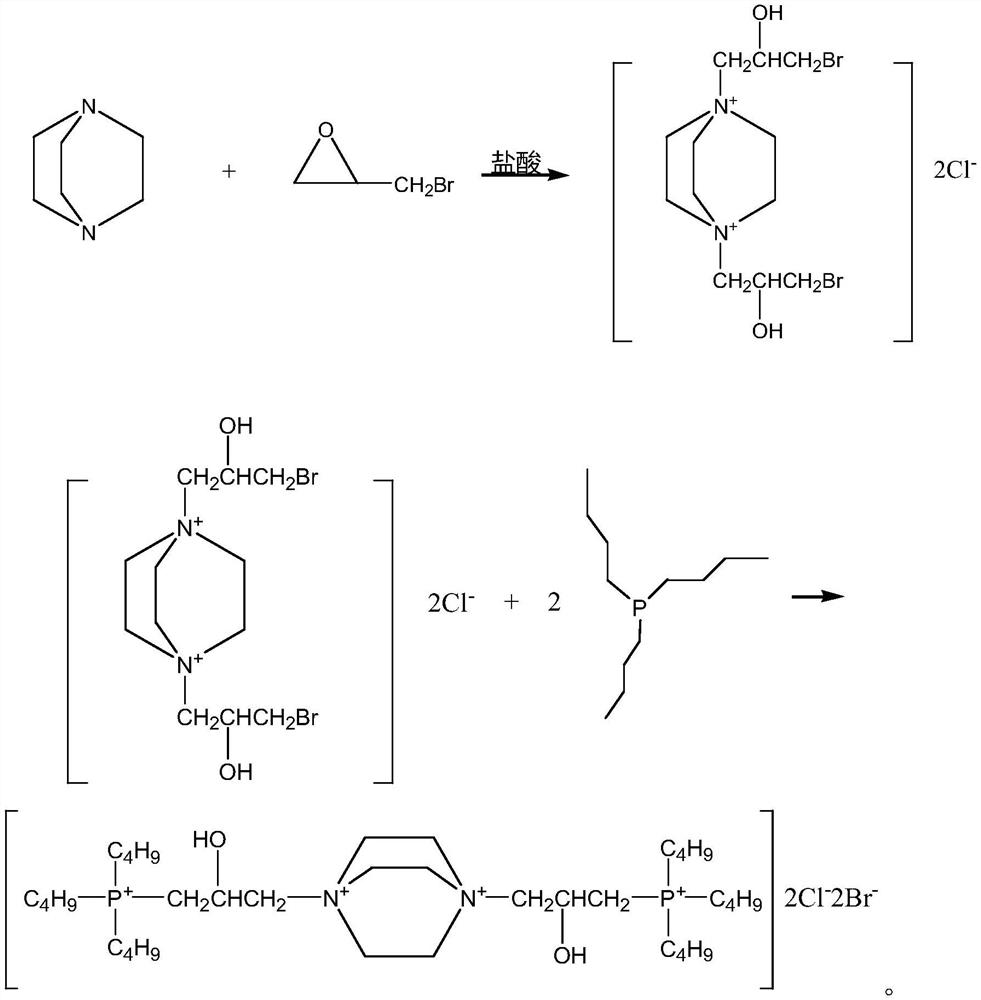

[0030] (1) Add 0.1mol triethylenediamine, 0.2mol 30wt% hydrochloric acid, 56g ethanol to the reactor, slowly add 0.26mol epibromopropane dropwise, complete the dropwise addition, slowly heat up to 50°C, keep the temperature for 4h, and distill under reduced pressure to dryness to obtain a viscous intermediate;

[0031] (2) 112g of ethanol and 0.2mol of tert-butylphosphine were added in the reactor, heated to reflux for 24h, and distilled to dryness under reduced pressure to obtain a crude product;

[0032] (3) add 67.2g of n-hexane in the crude product, heat up to dissolve, filter, cool the filtrate to below 10°C, separate out crystals, and dry in 100°C oven overnight to obtain product Q 1 .

Embodiment 2

[0034] (1) Add 0.1mol triethylenediamine, 0.26mol 30wt% hydrochloric acid, 224g ethanol in the reactor, slowly add 0.2mol epibromopropane dropwise, complete the dropwise addition, slowly heat up to 55°C, keep the temperature for 8h, and distill under reduced pressure to dryness to obtain a viscous intermediate;

[0035] (2) 336g of ethanol and 0.24mol of tert-butylphosphine were added in the reactor, heated to reflux for 72h, and distilled to dryness under reduced pressure to obtain a crude product;

[0036] (3) add 112g n-hexane in crude product, heat up and dissolve, filter, cool the filtrate to below 10 ℃, separate out crystal, 120 ℃ of oven drying overnight, obtain product Q 2 .

Embodiment 3

[0038] (1) Add 0.1mol triethylenediamine, 0.22mol 30wt% hydrochloric acid, 88g ethanol in the reactor, slowly add 0.25mol epibromopropane dropwise, complete the dropwise addition, slowly heat up to 52°C, keep the temperature for 5h, and distill under reduced pressure to dryness to obtain a viscous intermediate;

[0039] (2) 180g of ethanol and 0.21mol of tert-butylphosphine were added in the reactor, heated to reflux for 36h, and distilled to dryness under reduced pressure to obtain a crude product;

[0040] (3) add 74g n-hexane in the crude product, heat up and dissolve, filter, the filtrate is cooled to below 10 ℃, separate out crystal, 120 ℃ of oven oven dry overnight, obtain product Q 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com