Temperature-resistant environment-friendly infrared stealth material with waveband selection and low emissivity and preparation method thereof

A technology of band selection and stealth materials, applied in metal material coating technology, camouflage paint, vacuum evaporation coating, etc., can solve the problems of high temperature infrared emissivity, infrared stealth materials cannot be used for a long time, and difficult visible light stealth compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

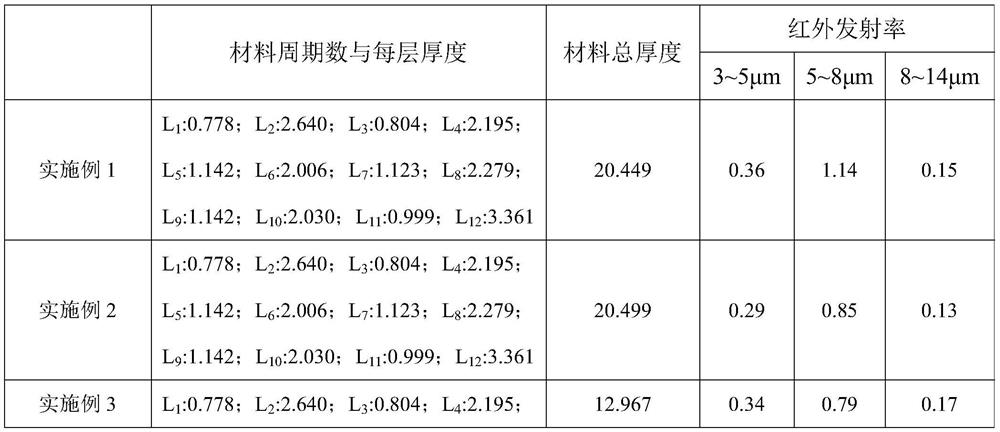

Embodiment 1

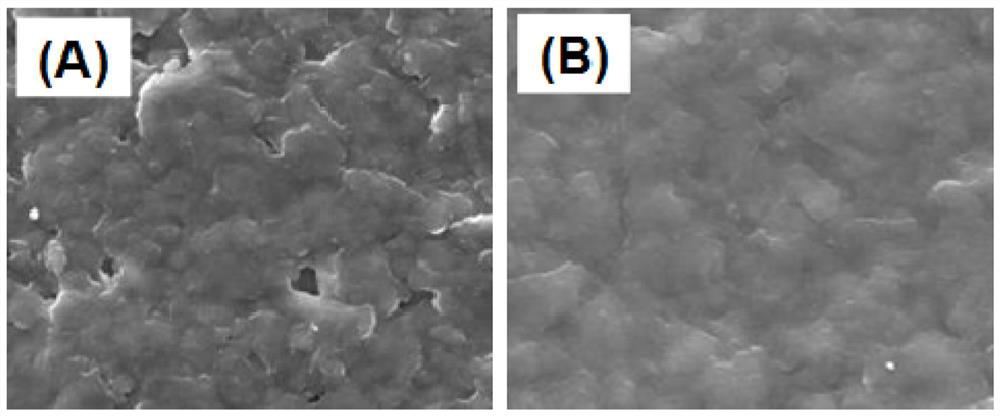

[0030] A kind of infrared stealth material with band selection, low emission, temperature resistance and environmental protection, including a relatively high refractive index (n 涂 =3.55~3.74) and infrared stealth coatings with relatively low refractive index (n 膜 = 1.12~1.25) of the infrared stealth film alternately plated to form the periodic infrared stealth material, in this embodiment, the number of cycles is six, and the first layer of material close to the metal substrate is the infrared stealth coating material. The thicknesses of the materials are all close to λ / 4, respectively.

[0031] The infrared stealth coating in this embodiment includes the following raw materials by weight:

[0032] Metal filler: 35%, binder: 58%, pigment: 1.5%, auxiliary agent: 5.5%.

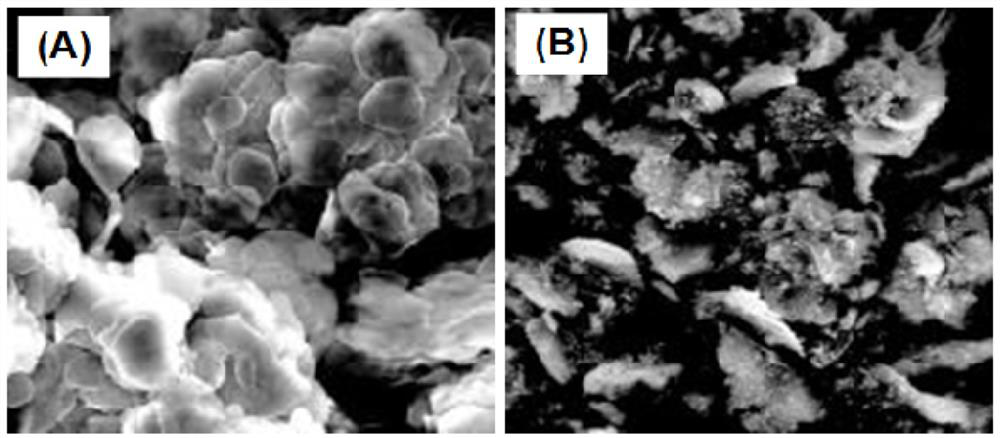

[0033] It should be noted that, in this embodiment, the metal filler is Al / Cr obtained by flaky aluminum powder after being treated by liquid deposition surface coating technology 2 O 3 . The binder is an ...

Embodiment 2

[0046] A kind of infrared stealth material with band selection, low emission, temperature resistance and environmental protection, including a relatively high refractive index (n 涂 =3.55~3.74) and infrared stealth coatings with relatively low refractive index (n 膜 = 1.12~1.25) of the infrared stealth film alternately plated to form the periodic infrared stealth material, in this embodiment, the number of cycles is six, and the first layer of material close to the metal substrate is the infrared stealth coating material. The thicknesses of the materials are all close to λ / 4, respectively.

[0047] The infrared stealth coating in this embodiment includes the following raw materials by weight:

[0048] Metal filler: 40%, binder: 55%, pigment: 2.5%, auxiliary agent: 2.5%.

[0049] In the examples of the present application, the metal filler is Al / Cr obtained by the treatment of flake aluminum powder by liquid deposition surface coating technology 2 O 3 . The binder is an aque...

Embodiment 3

[0062] A kind of infrared stealth material with band selection, low emission, temperature resistance and environmental protection, including a relatively high refractive index (n 涂 =3.55~3.74) and infrared stealth coatings with relatively low refractive index (n 膜 = 1.12-1.25) of the periodic infrared stealth film alternately plated with infrared stealth film, in this embodiment, the number of cycles is four, and the first layer of material close to the metal substrate is the infrared stealth coating material. The thicknesses of the materials are all close to λ / 4, respectively.

[0063] The infrared stealth coating in this embodiment includes the following raw materials by weight:

[0064] Metal filler: 35%, binder: 58%, pigment: 1.5%, auxiliary agent: 5.5%.

[0065] In this embodiment, the metal filler is Al / Cr obtained by flaky aluminum powder after being treated by liquid deposition surface coating technology 2 O 3 . The binder is an aqueous silicate binder. The pigme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com