UV peelable adhesive containing free radical system

A free radical and peeling adhesive technology, which is applied in the field of pressure-sensitive adhesives, can solve the problems of high cost, high peeling force part difficulties, and failure to master the core technology, etc., to achieve excellent comprehensive performance of the product, improve cohesive strength and adhesive performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

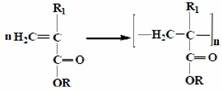

Method used

Image

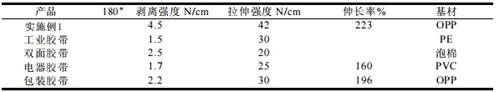

Examples

Embodiment 1

[0019] The present embodiment provides a UV strippable adhesive containing a free radical system, comprising the following components by weight:

[0020] 70 parts of acrylic modified silicone resin,

[0021] 30 parts of trifunctional urethane acrylate,

[0022] 5 parts methyl methacrylate,

[0023] 18 parts of isobornyl acrylate,

[0024] Photoinitiator 1173: 3 parts;

[0025] Add UV free radical initiator, methyl methacrylate, reactive diluent and acrylic modified silicone resin to a container with a stirrer and a thermometer, stir at a constant speed for 4-6min, and irradiate the container with a UV LED light source with a wavelength of 3265nm. Initiate the polymerization of the monomers until the temperature no longer rises and then stop lighting; the prepared acrylate-based adhesive is mixed with trifunctional urethane acrylate to prepare UV light-induced peelable adhesive.

[0026] The trifunctional urethane acrylate of this embodiment is composed of 20 parts by weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com