Method for enhancing co-digestion of kitchen waste and activated sludge to produce acid through freezing/temperature pretreatment

A technology for kitchen waste and activated sludge, which is applied in the direction of temperature control sludge treatment, biological sludge treatment, fermentation, etc., can solve the problems of ecological pollution and large-scale discharge of kitchen waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

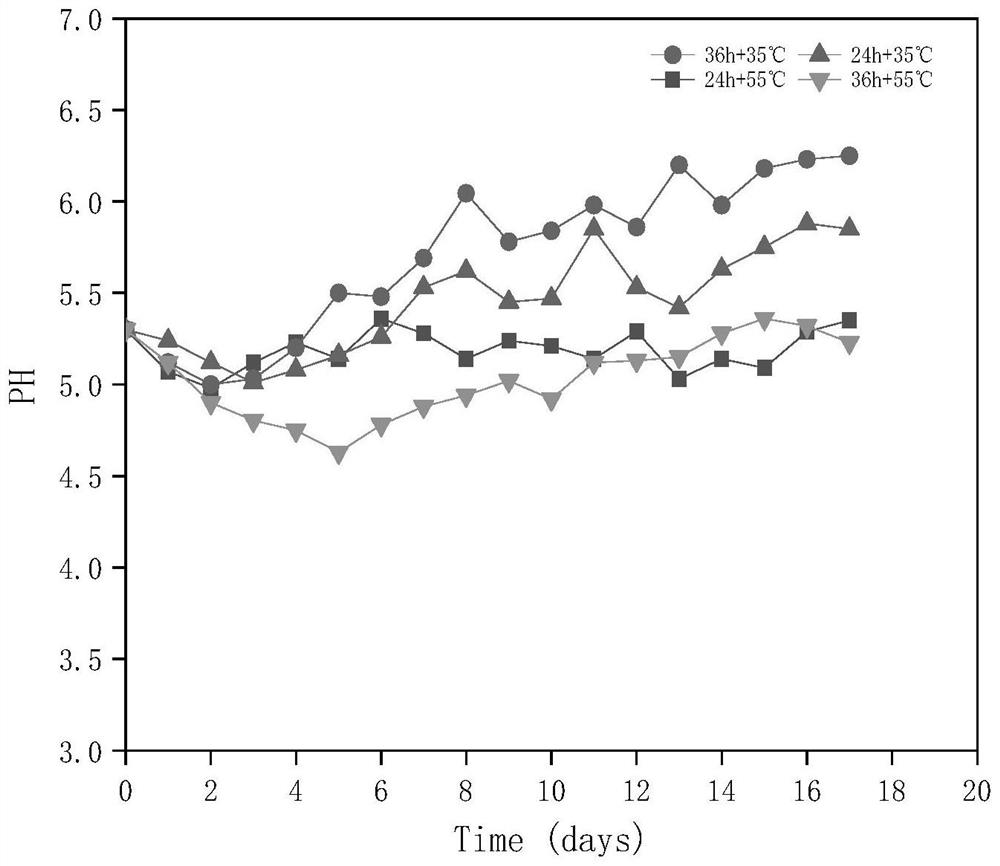

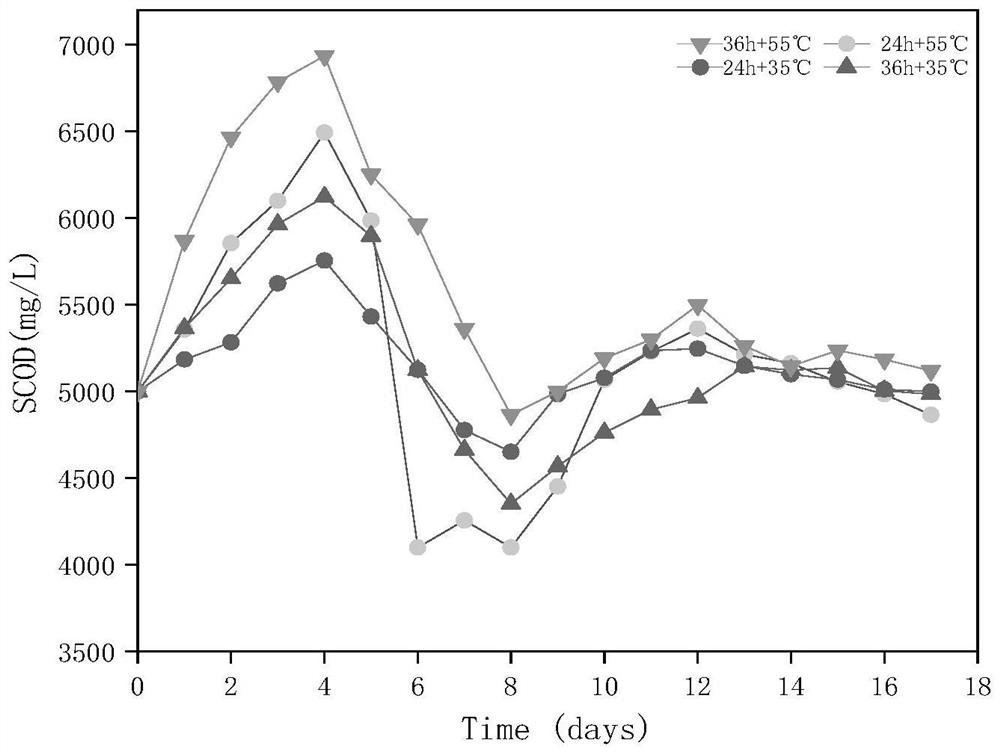

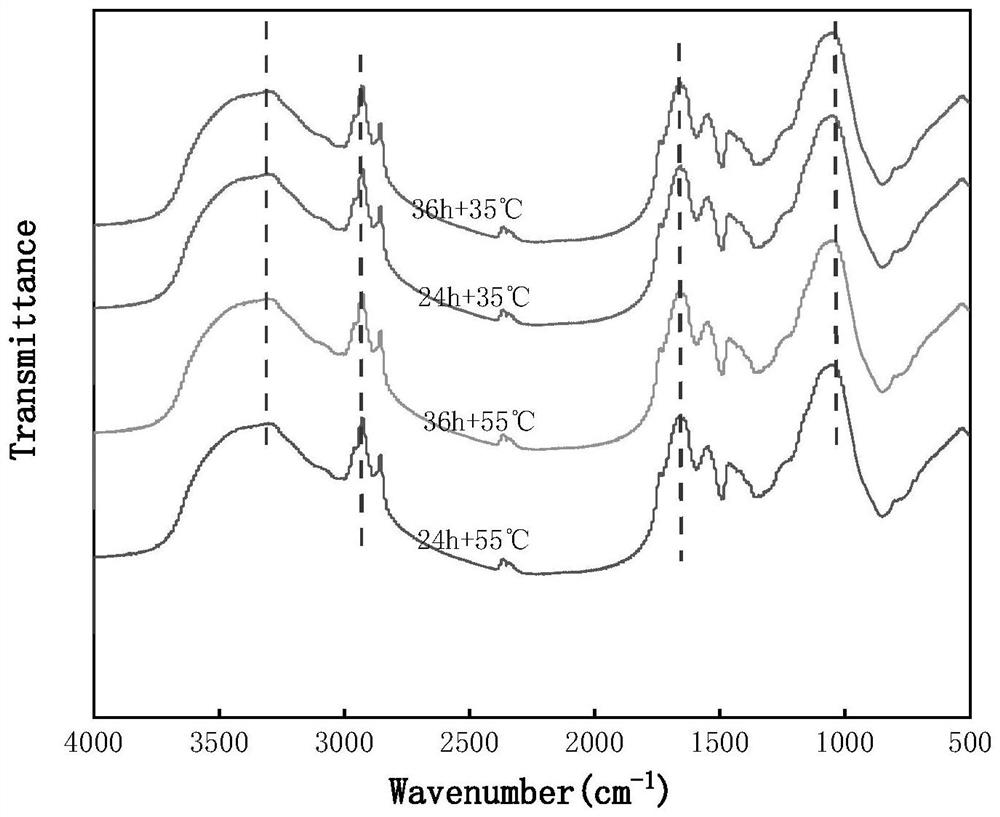

example 1

[0030] (1) Pulverization and mixing of kitchen waste and activated sludge: First, screen the kitchen waste to remove bones, paper and plastic, and then use an electric mixer to pulverize to a kitchen waste slurry with a particle size of less than 2 mm; Dilute to a total solid content of 10%; dilute the activated sludge from the sewage biological treatment system to a total solid content of 10%; divide the above-mentioned treated kitchen waste slurry and activated sludge according to volume 1:

[0031] 1 Mix evenly;

[0032] (2) Pretreatment of the mixed solution: the mixed solution of the above-mentioned kitchen waste slurry and activated sludge was frozen at -20°C for 24 hours, and returned to room temperature of 20°C after freezing; 2 The air at the top of the mixed solution was blown off for 10 minutes, and the original air in the device was exhausted; the mixed solution after the above treatment was placed at 35°C for anaerobic fermentation for 18 days.

[0033] (3) Take 20...

example 2

[0039] (1) Pulverization and mixing of kitchen waste and activated sludge: First, screen the kitchen waste to remove bones, paper and plastic, and then use an electric mixer to pulverize to a kitchen waste slurry with a particle size of less than 2 mm; Dilute to a total solid content of 10%; dilute the activated sludge from the sewage biological treatment system to a total solid content of 10%; divide the above-mentioned treated kitchen waste slurry and activated sludge according to volume 1:

[0040] 1 Mix evenly;

[0041] (2) Pretreatment of the mixed solution: the mixed solution of the above-mentioned kitchen waste slurry and activated sludge was frozen at -20°C for 24 hours, and returned to room temperature of 20°C after freezing; 2 The air at the top of the mixed solution was blown off for 10 min, and the original air in the device was exhausted; the mixed solution after the above treatment was placed at 55 °C for anaerobic fermentation for 18 d.

[0042] (3) Take 20ml o...

example 3

[0047] (1) Pulverization and mixing of kitchen waste and activated sludge: First, screen the kitchen waste to remove bones, paper and plastic, and then use an electric mixer to pulverize to a kitchen waste slurry with a particle size of less than 2 mm; Dilute to a total solid content of 10%; dilute the activated sludge from the sewage biological treatment system to a total solid content of 10%; divide the above-mentioned treated kitchen waste slurry and activated sludge according to volume 1:

[0048] 1 Mix evenly;

[0049] (2) Pretreatment of the mixed solution: The mixed solution of the above-mentioned kitchen waste slurry and activated sludge was frozen at -20°C for 36 hours, and returned to room temperature of 20°C after freezing; 2 The air at the top of the mixed solution was blown off for 10 minutes, and the original air in the device was exhausted; the mixed solution after the above treatment was placed at 35°C for anaerobic fermentation for 18 days.

[0050] (3) Take ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com