Method for preparing solid electrolyte by dry method and application thereof

A solid electrolyte and dry method technology, applied in circuits, electrical components, secondary batteries, etc., can solve problems such as serious residual alkali, sample sticking to the wall, and yield drop, so as to improve fluidity and moisture retention, and increase yield And the effect of high quality and high commercial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A specific embodiment of the present invention provides a method for preparing a solid electrolyte, comprising:

[0032] According to the elemental composition of the target electrolyte molecular formula, the preparation raw materials are batched according to the stoichiometric ratio therein;

[0033] The preparation raw materials and organic additives are uniformly mixed by dry method using mixing equipment;

[0034] The mixed powder is calcined and obtained.

Embodiment 1

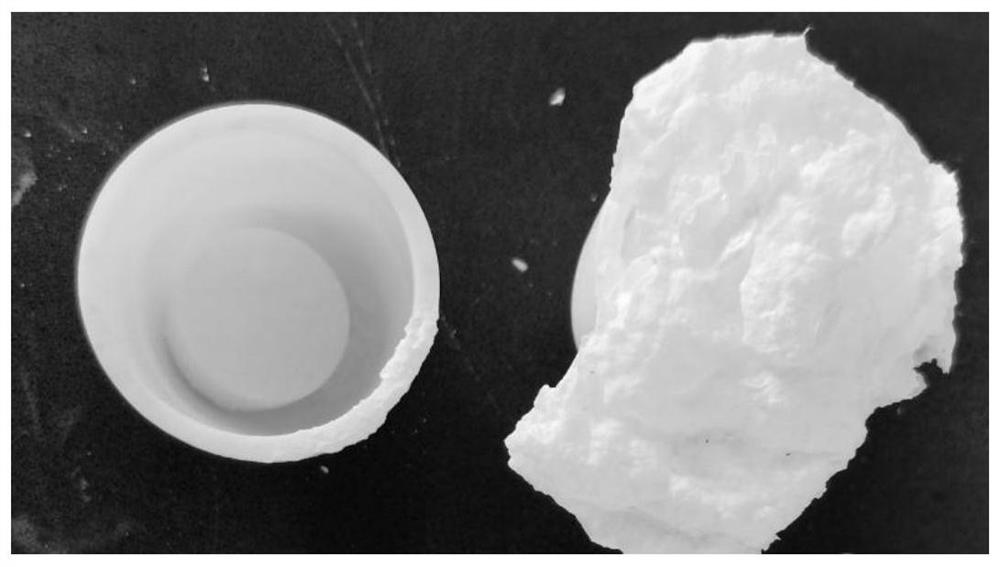

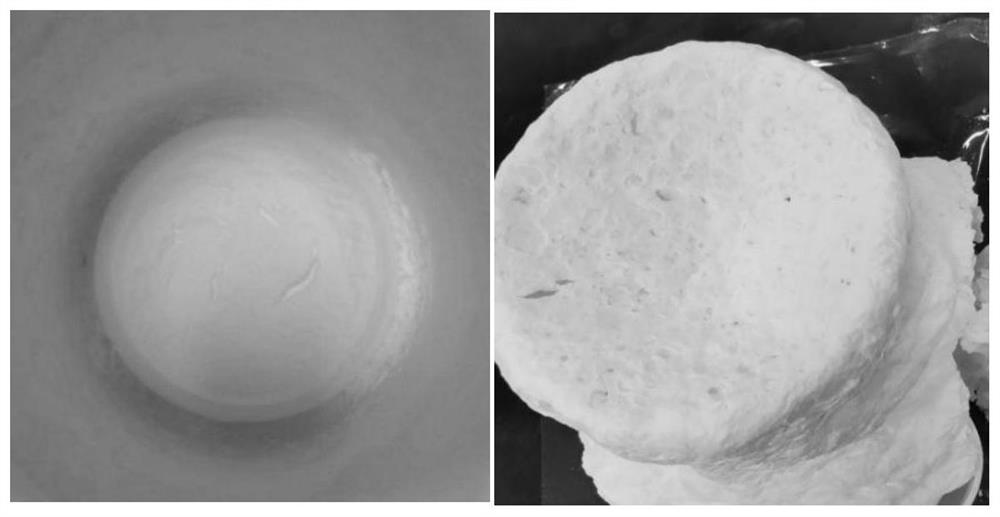

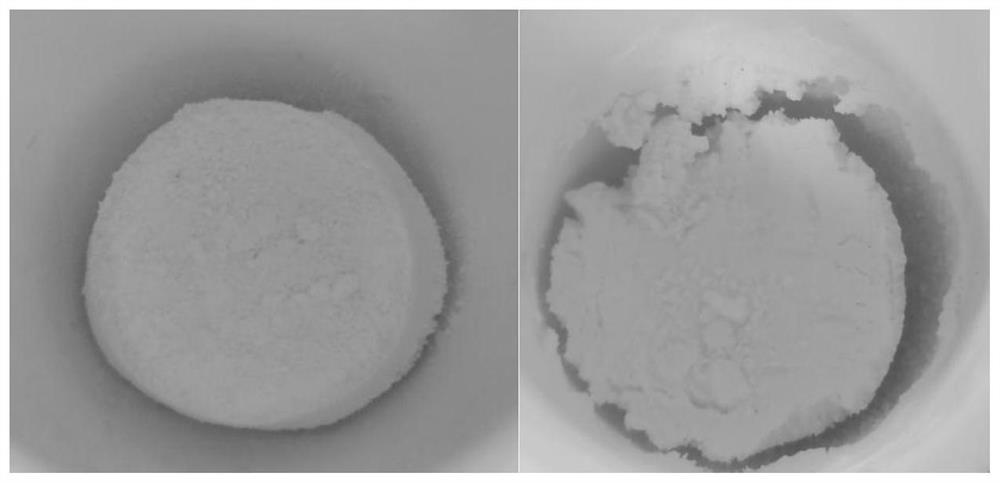

[0062] The target products obtained in Example 1 and Comparative Example 1, Example 4 and Comparative Example 4, Example 6 and Comparative Example 6, Example 7 and Comparative Example 7, Example 9 and Comparative Example 9 are respectively as follows: Figures 1 to 5 shown. Comparative example 1 / 4 / 6 / 7 / 9 belongs to the preparation of electrolyte by using ordinary dry mixing raw materials. The synthesized electrolyte has obvious expansion and wall sticking phenomenon. The material overflows the crucible and is firmly combined with the crucible. Take out, the yield is only 70.9%. Examples 1 / 4 / 6 / 7 / 9 use additives to dry mix the raw materials, the synthesized electrolyte does not expand, the material shrinks into a block, and does not stick to the crucible, and the yield is greatly improved, up to 97%. In addition, the results of other examples and comparative examples also show that adding organic additives to the solid electrolyte prepared by dry method can effectively increase ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com