Municipal sludge treatment and utilization method

A technology for municipal sludge and sludge, which is applied in sludge treatment, biological sludge treatment, water/sludge/sewage treatment, etc., can solve the problems of difficult recycling, complicated methods, chemical pollution, etc., and achieve significant economic benefits. and social benefits, improve soil fertility, and avoid the effects of enrichment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

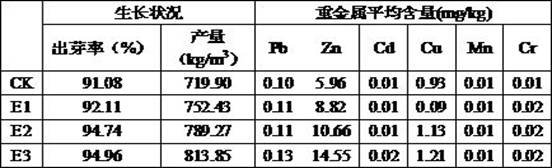

Embodiment 1

[0030] A kind of municipal sludge treatment utilization method of the present invention comprises the following steps:

[0031] (1), heat treatment:

[0032] In order to eliminate the harm that sludge may cause to the environment, and to avoid the interference of microorganisms in sludge on nitrosifying bacteria and nitrifying bacteria, the municipal sludge was continuously heat-treated at 70°C for 45 minutes to kill the microorganisms in the sludge and improve the quality of sewage. Mud dehydration performance, and then cooled to room temperature 18-25 ℃;

[0033] (2), short-range nitrification reaction:

[0034] Add nitrous bacteria (also known as nitrosative bacteria, nitrosative bacteria agent, commercially available products) to the inactivated sludge, and the amount added is 1.5x10 of the dry sludge. 5 cells / g, when the concentration of dissolved oxygen is controlled at 0.4mg / L, nitrous bacteria can promote the conversion of ammonium nitrogen into nitrite nitrogen, and...

Embodiment 2

[0049] A kind of municipal sludge treatment utilization method of the present invention comprises the following steps:

[0050] (1), heat treatment:

[0051] In order to eliminate the harm that sludge may cause to the environment, and to avoid the interference of microorganisms in sludge on nitrosifying bacteria and nitrifying bacteria, the municipal sludge was continuously heat-treated at 78°C for 32 minutes to kill the microorganisms in the sludge and improve the quality of sewage. Mud dehydration performance, and then cooled to room temperature 18-25 ℃;

[0052] (2), short-range nitrification reaction:

[0053] Add nitrous bacteria (also known as nitrosative bacteria, nitrosative bacteria agent, commercially available products) to the inactivated sludge, the amount added is 1.2x10 of the dry sludge 5 cells / g (dry sludge is the sludge that has dehydrated), and the concentration of dissolved oxygen (DO) is controlled at 0.45mg / L. Nitrite bacteria can promote the conversion ...

Embodiment 3

[0061] A kind of municipal sludge treatment utilization method of the present invention comprises the following steps:

[0062] (1), heat treatment:

[0063] In order to eliminate the harm that sludge may cause to the environment, and to avoid the interference of microorganisms in sludge on nitrosifying bacteria and nitrifying bacteria, the municipal sludge was continuously heat-treated at 68°C for 58 minutes to kill the microorganisms in the sludge and improve the quality of sewage. Mud dehydration performance, and then cooled to room temperature 18-25 ℃;

[0064] (2), short-range nitrification reaction:

[0065] Add nitrous bacteria (also known as nitrosative bacteria, nitrosative bacteria agent, commercially available products) to the inactivated sludge, the amount added is 1.8x10 of the dry sludge 5 cells / g (dried sludge is sludge dehydrated), and the concentration of dissolved oxygen (DO) is controlled at 0.32mg / L. Nitrite bacteria can promote the conversion of ammonium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com