Organic ligand, preparation method thereof and catalyst for ethylene selective oligomerization

A technology of organic ligands and catalysts is applied in the field of catalysts for selective oligomerization of ethylene, which can solve the problems of insufficient production capacity of advanced linear α-olefins, and achieve the effects of rapid separation, reliable and high activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

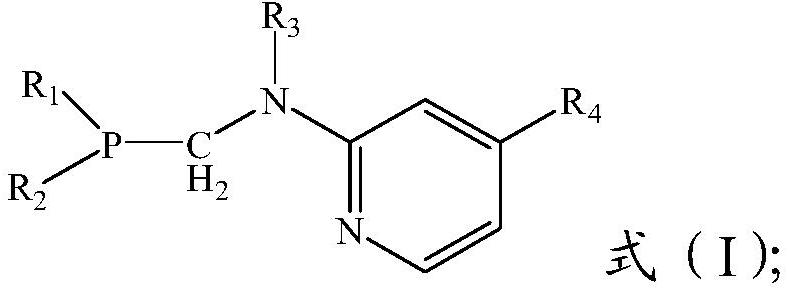

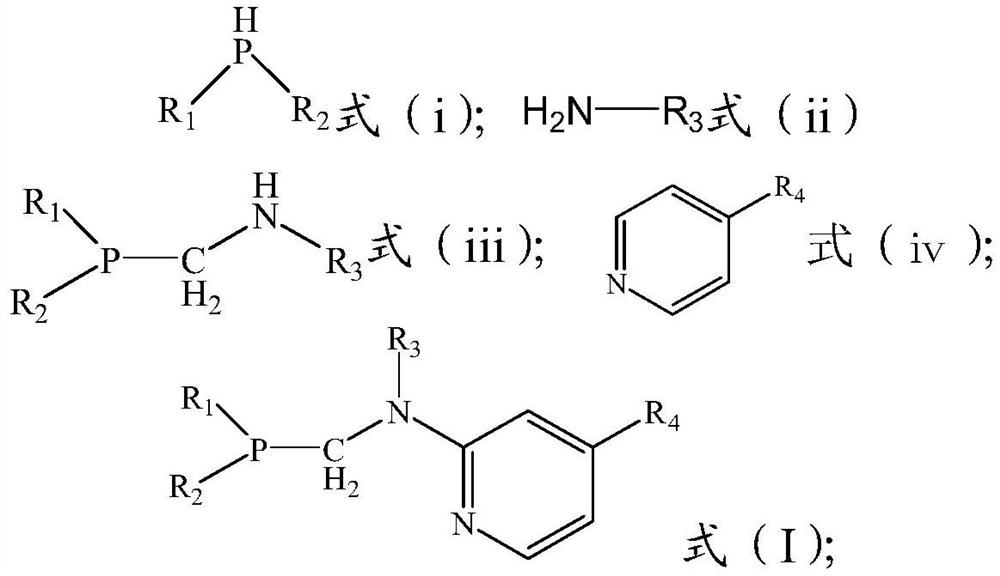

[0042] The invention provides a preparation method of an organic ligand, comprising the following steps:

[0043] a) reacting the phosphine compound of formula (i), paraformaldehyde and the primary amine of formula (ii) in a solvent to obtain an intermediate of formula (iii);

[0044] b) in the presence of triethylamine, the intermediate of the formula (iii) is mixed with the para-substituted pyridine of the structure of the formula (iv) to obtain the organic ligand of the formula (I);

[0045]

[0046] R 1 and R 2independently selected from substituted or unsubstituted C1-C10 alkyl, C1-C10 alkenyl; C6-C10 cycloalkyl, C6-C10 aryl;

[0047] R 3 Selected from C1-C10 alkyl, C6-C10 cycloalkyl, C6-C10 aryl;

[0048] R 4 It is selected from halogen, C1-C10 alkyl, C1-C10 alkenyl or C6-C10 cycloalkyl.

[0049] In the preparation method provided by the present invention, firstly, the structural phosphine of formula (i), paraformaldehyde and the primary amine of formula (ii) ar...

Embodiment 1

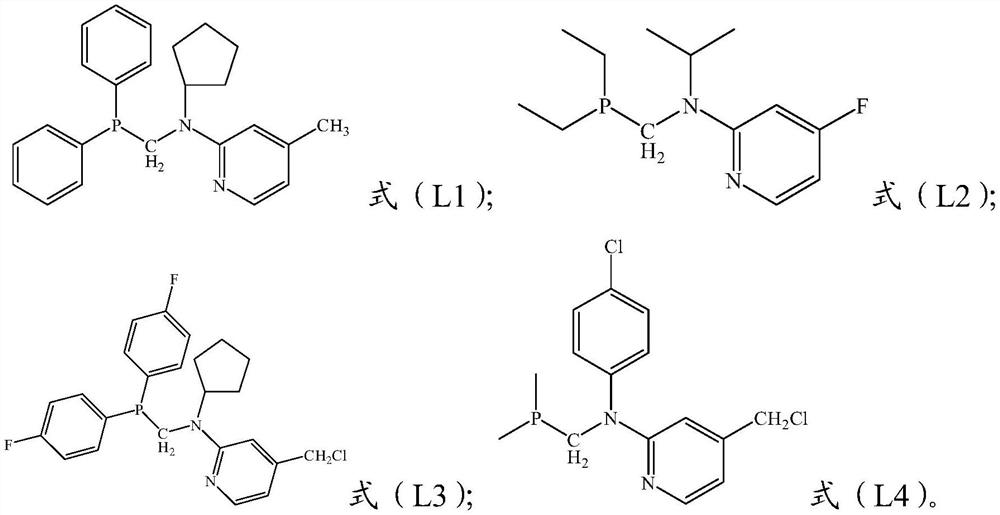

[0070] 1) Synthesis of ligand L1:

[0071]

[0072] The first step, diphenylphosphine (0.1mol), paraformaldehyde (polymerization degree is 2-10, with -CH 2 The number of moles in terms of O- is 0.12mol) and cyclopentylamine (0.12mol) were added to 100mL of methanol and toluene (v / v=2:1) solution, heated to reflux overnight, and then cooled to room temperature. The solvent was distilled off under reduced pressure to obtain a yellow oil, which was dissolved in 20 mL of THF, dried over anhydrous magnesium sulfate, filtered, the filtrate was distilled under reduced pressure, 15 mL of ether was added, and the precipitated solid was precipitated with a yield of 91 %;

[0073] In the second step, the solid precipitate (0.11 mol) was dissolved in 80 mL of ether, triethylamine (0.15 mol) was added and stirred for 20 min, the mixture was cooled to 0°C, and 4-picoline (0.12 mol) was added dropwise to the reaction solution. ), continue to stir for 30 min after the dropwise addition...

Embodiment 2

[0080] 1) Synthesis of ligand L2:

[0081]

[0082] The first step, diethylphosphine (0.1mol), paraformaldehyde (polymerization degree is 2-10, with -CH 2 The number of moles in terms of O- is 0.12 mol) and isopropylamine (0.12 mol) were added to 100 mL of methanol and toluene (v / v=2:1) solution, heated to reflux overnight, then cooled to room temperature, and the reaction solution was reduced The solvent was distilled off under pressure to obtain a yellow oil, which was dissolved in 30 mL of THF, dried with anhydrous magnesium sulfate, filtered, the filtrate was distilled under reduced pressure, 20 mL of ether was added, the precipitated solid was precipitated, and the yield was 90%. ;

[0083] In the second step, the solid precipitate (0.105mol) was dissolved in 80mL of ether, triethylamine (0.18mol) was added and stirred for 20min, the mixture was cooled to 0°C, and 4-fluoropyridine (0.11mol) was added dropwise to the reaction solution. , continue to stir for 30 min ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap