Super-hydrophobic corrosion-resistant paint for grounding electrode and preparation method of coating of super-hydrophobic corrosion-resistant paint

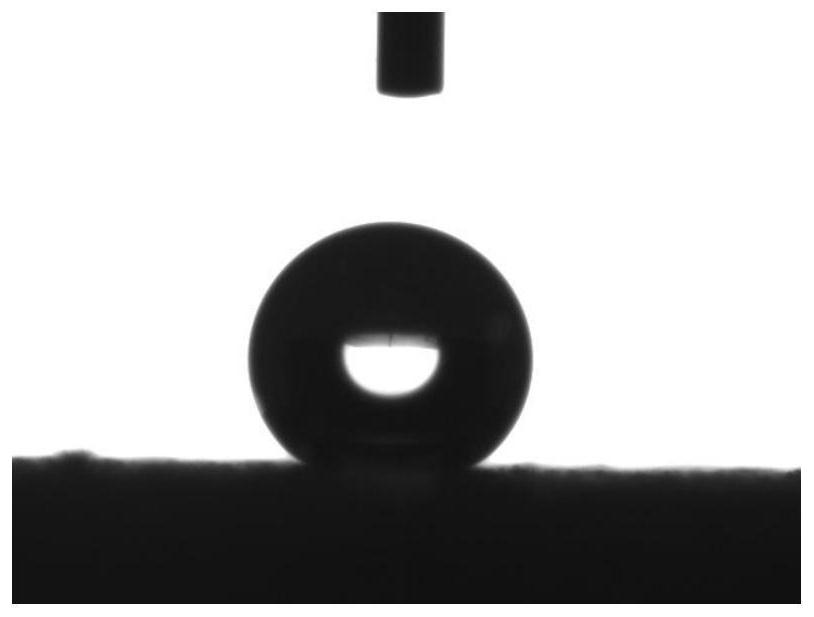

A super-hydrophobic, grounding electrode technology, applied in coatings, conductive coatings, anti-corrosion coatings, etc., can solve the problems of poor compatibility between metals and resins, weak conductivity, easy to corrode, etc., and achieve good conductivity and oxidation resistance. Enhanced, no environmental pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

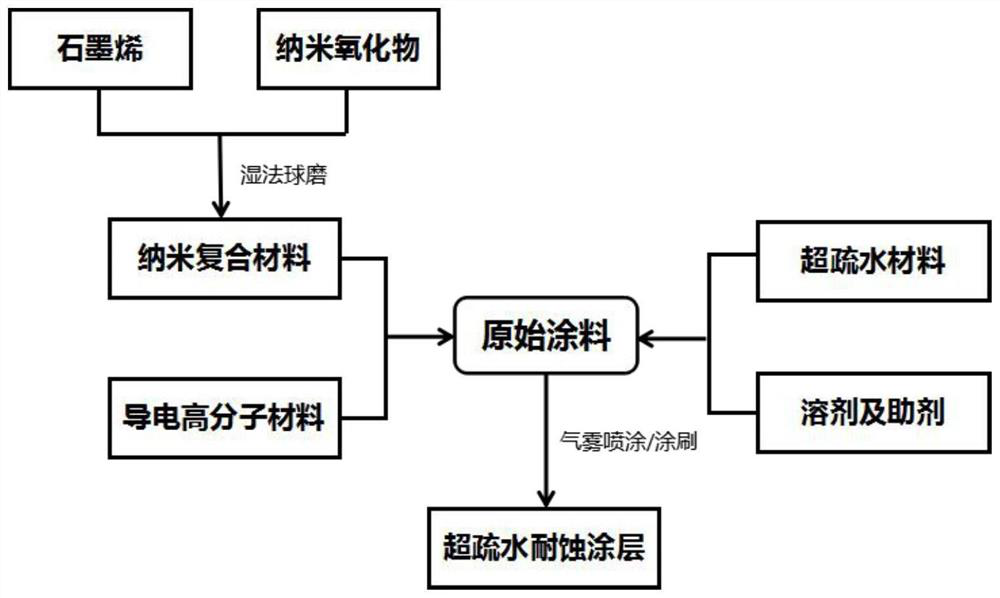

Method used

Image

Examples

specific Embodiment approach 1

[0018] Embodiment 1: In this embodiment, a super-hydrophobic corrosion-resistant coating for grounding electrodes is composed of 10-30 parts by mass of conductive polymer materials, 20-50 parts of nano-composite materials, 40-65 parts of super-hydrophobic materials, It is composed of 2-10 parts of solvent and 0.35-2 parts of auxiliary agent; the nano-composite material is graphene-modified nano-oxide particles.

specific Embodiment approach 2

[0019] Embodiment 2: This embodiment is different from Embodiment 1 in that the conductive polymer material is polyaniline, polypyrrole or polythiophene. Others are the same as the first embodiment.

specific Embodiment approach 3

[0020] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the nano-oxide particles are nano-titanium dioxide, nano-silicon dioxide, nano-zinc oxide or nano-alumina, and the particle size of the nano-oxide particles is 5 to 50 nm. The specific embodiment one or two are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com