High-strength cast magnesium alloy and preparation method thereof

A high-strength casting magnesium alloy technology, which is applied in the field of high-strength casting magnesium alloys and its preparation, can solve the problems of inability to prepare high-performance magnesium alloys, achieve the effects of inhibiting grain growth, inhibiting growth, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

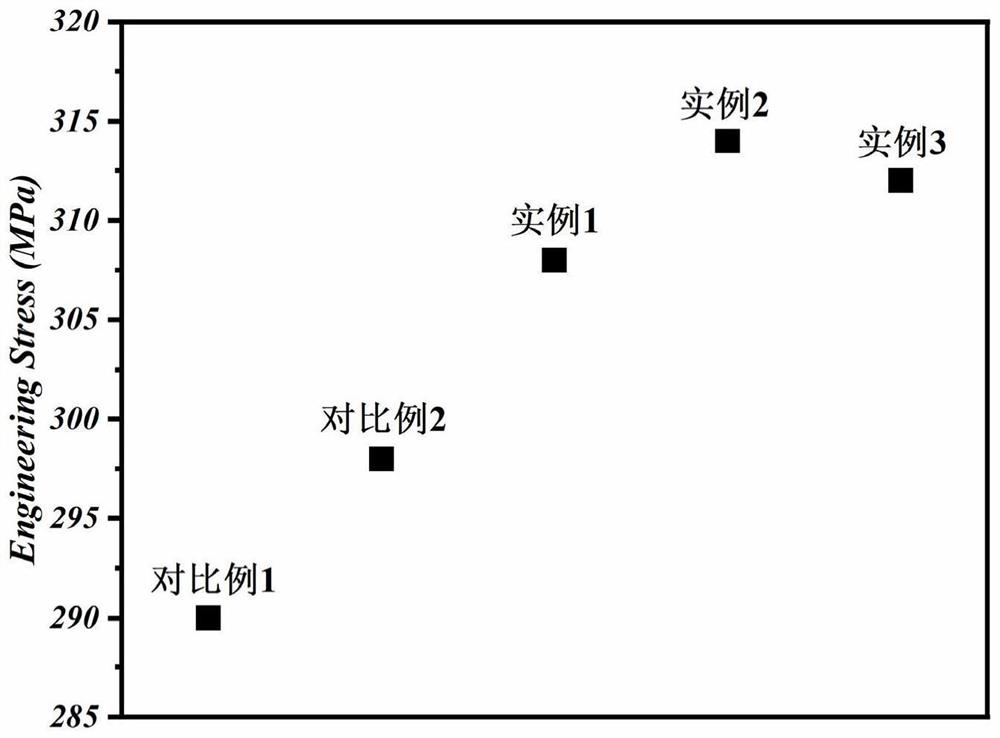

Embodiment 1

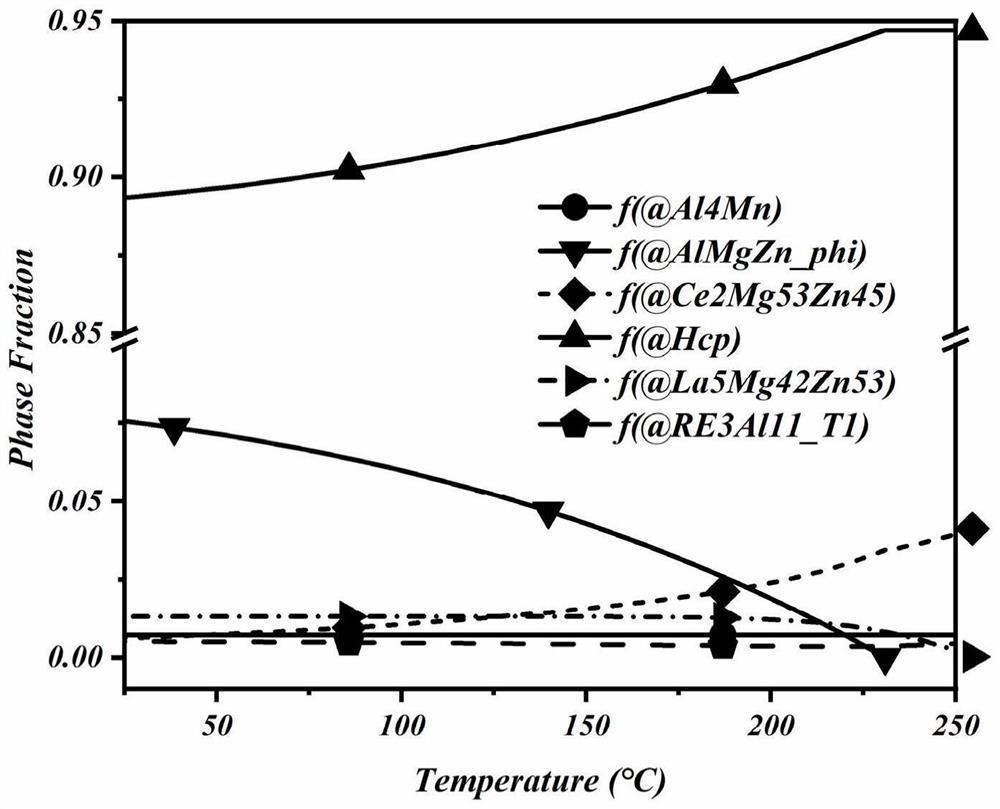

[0036] (1) Ingredients: prepare Zn 7.0%, Al 3.0%, Mg-5wt.% Mn 0.4%, RE 1.0%, the total amount of impurities less than 0.04%, the balance is Mg, where RE includes La and Ce, La and Ce They account for 35% and 65% of the total added amount of RE, respectively. La and Ce are added in the form of Mg-30wt.%La and Mg-30wt.%Ce master alloys. The above raw materials are polished, and the oxide film on the surface of the raw materials is polished. removed, and then dried.

[0037] (2) Put the dried Al, Mg-5wt.%Mn and Mg into the cleaned iron crucible first and smelt in the resistance furnace, the smelting temperature is controlled at 740°C, and the volume ratio is 99%: 1% during smelting CO 2 and SF 6 As a protective gas; after all the metals in the crucible are melted, Zn, Mg-30wt.%La and Mg-30wt.%Ce are finally added, and smelted for 20 minutes to initially obtain an alloy melt.

[0038] (3) Melt purification: After obtaining the preliminary alloy melt, RJ-6 refining agent is used...

Embodiment 2

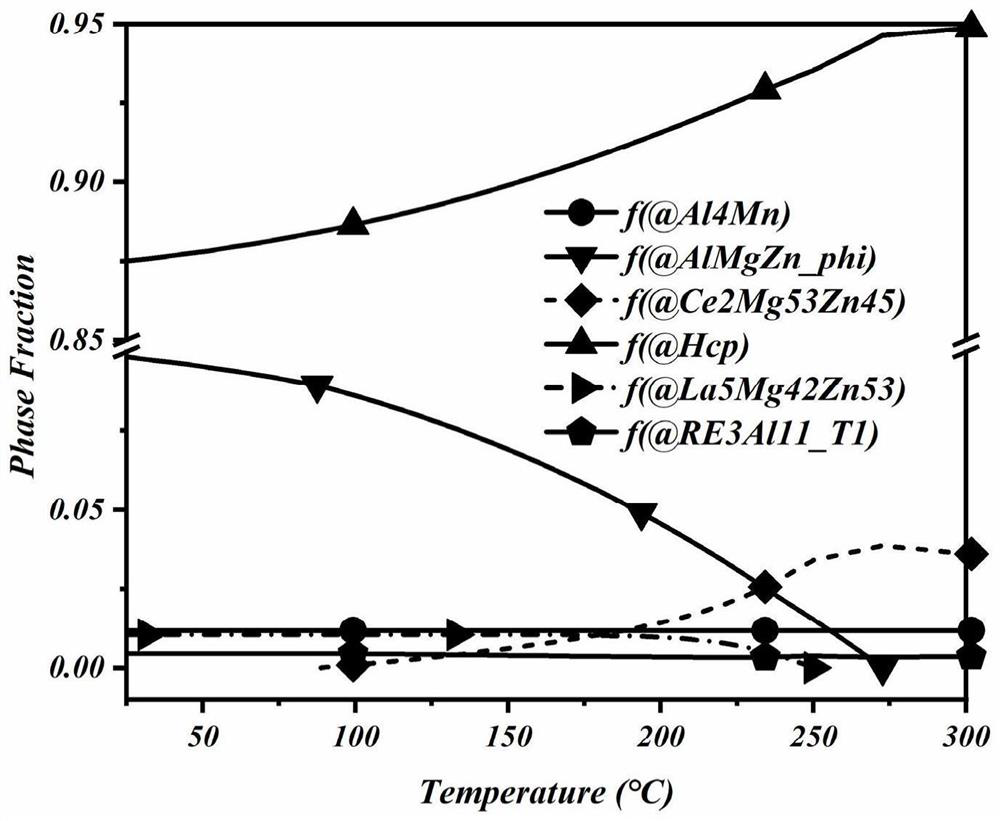

[0042] (1) Ingredients: Prepare Zn 7.0%, Al 4.0%, Mg-5wt.% Mn 0.3%, RE 0.8%, the total amount of impurities less than 0.04%, the balance is Mg, where RE includes La and Ce, La and Ce They account for 35% and 65% of the total added amount of RE, respectively. La and Ce are added in the form of Mg-30wt.%La and Mg-30wt.%Ce master alloys. The above raw materials are polished, and the oxide film on the surface of the raw materials is polished. removed, and then dried.

[0043] (2) Put the dried Al, Mg-5wt.% Mn and Mg into a cleaned iron crucible and smelt in a resistance furnace, the smelting temperature is controlled at 750°C, and the volume ratio is 99%: 1% during smelting CO 2 and SF 6 As protective gas; after all the metals in the crucible are melted, Zn, Mg-30wt.%La and Mg-30wt.%Ce are finally added, and smelted for 18 minutes to initially obtain an alloy melt.

[0044] (3) Melt purification: After obtaining the preliminary alloy melt, RJ-6 refining agent is used to purify ...

Embodiment 3

[0048] (1) Ingredients: prepare Zn 7.0%, Al 5.0%, Mg-5wt.% Mn 0.5%, RE 0.5%, the total amount of impurities less than 0.04%, the balance is Mg, where RE includes La and Ce, La and Ce They account for 35% and 65% of the total added amount of RE, respectively. La and Ce are added in the form of Mg-30wt.%La and Mg-30wt.%Ce master alloys. The above raw materials are polished, and the oxide film on the surface of the raw materials is polished. removed, and then dried.

[0049] (2) Put the dried Al, Mg-5wt.%Mn and Mg into the cleaned iron crucible first and smelt in the resistance furnace, the smelting temperature is controlled at 760°C, and the volume ratio is 99%: 1% during smelting CO 2 and SF 6 As protective gas; after all the metals in the crucible are melted, Zn, Mg-30wt.%La and Mg-30wt.%Ce are finally added, and smelted for 15 minutes to initially obtain an alloy melt.

[0050] (3) Melt purification: After obtaining the preliminary alloy melt, RJ-6 refining agent is used t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com