Intelligent prestressed member welded with macromolecule packaging strain gauge and manufacturing method of intelligent prestressed member

A manufacturing method and polymer technology, which can be used in building components, bridge parts, measuring devices, etc., can solve problems such as poor adhesion and falling off, and achieve the effects of improving sensing sensitivity, good packaging, and avoiding aging and debonding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

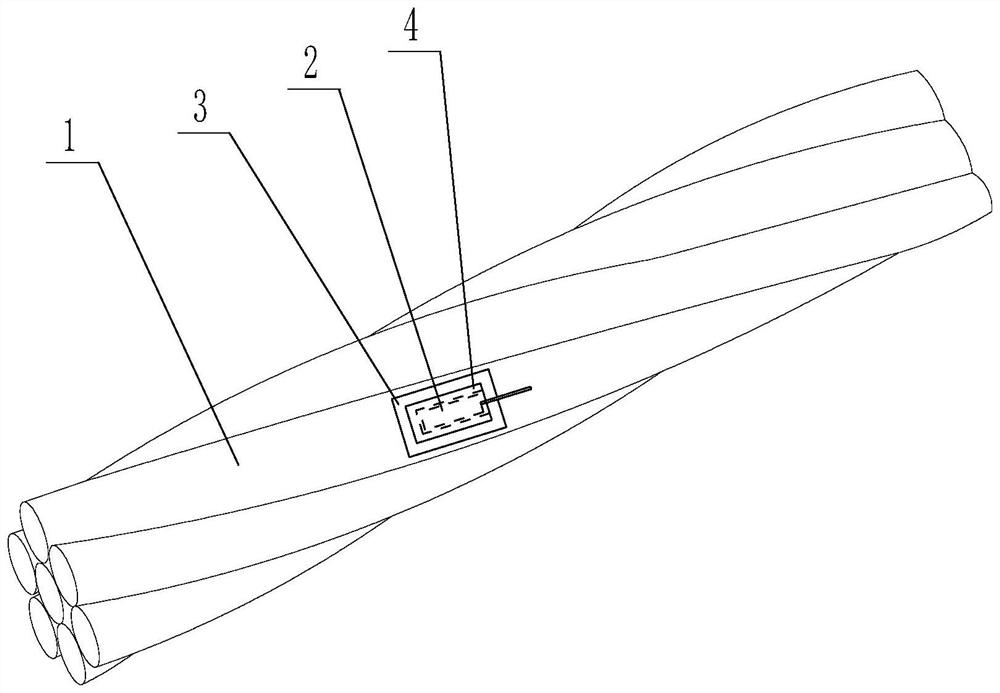

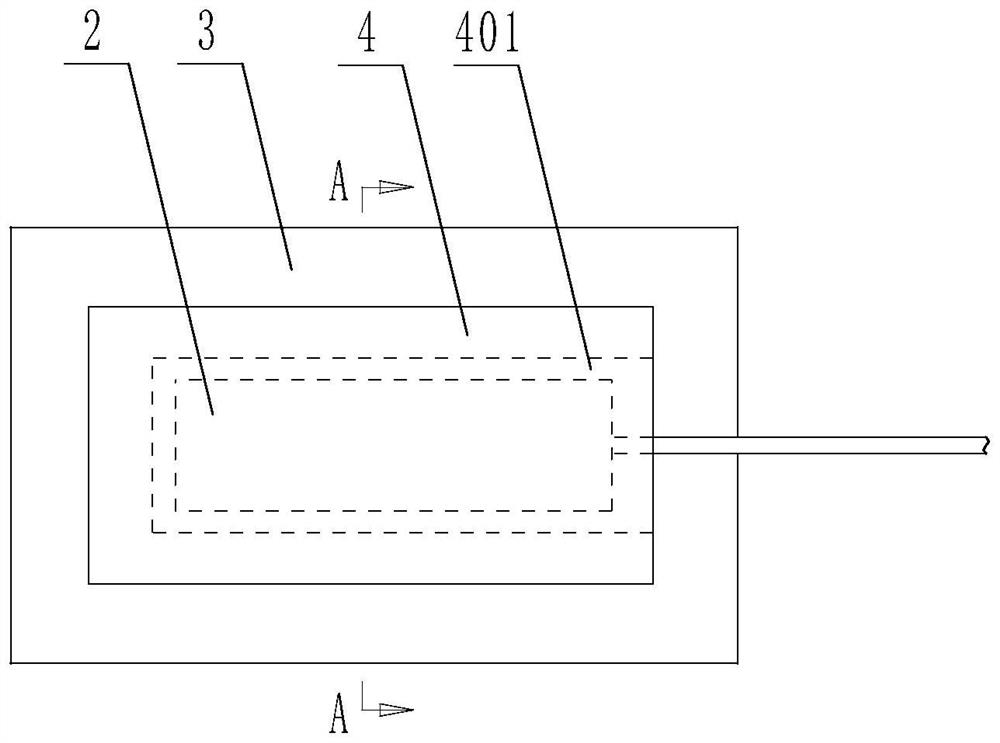

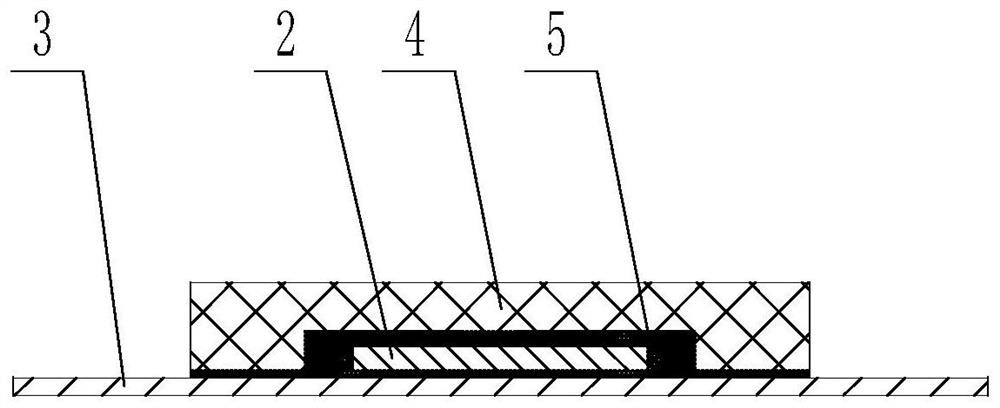

[0041] figure 1 Disclosed is an intelligent prestressed component welded with a polymer packaged strain gauge, including a prestressed rib 1—steel strand, a polymer packaged strain gauge, and the polymer packaged strain gauge includes a strain gauge 2, a foil Sheet 3, polymer sealing plate 4 (see figure 2 ); the foil 3 is a stainless steel foil with a thickness of 0.1mm∼0.2mm, the strain gauge 2 is pasted and fixed on the foil 3, and the polymer sealing plate 4 is made of polytetrafluoroethylene with heat resistance above 250°C The bottom of the polymer sealing plate 4 is bonded and fixed on the foil 3, and the bottom of the polymer sealing plate 4 is provided with a cavity, the cavity is covered on the strain gauge 2, and the cavity is filled with the adhesive 5; the The foil 3 is spot welded on the prestressed rib 1 by a spot welding machine, which is a portable lithium battery spot welding machine, and the spot welding voltage is 1V to 5V.

[0042] The materials used for...

Embodiment 2

[0044] A manufacturing method of an intelligent prestressed component welded with a polymer encapsulated strain gauge, the method comprising the following steps:

[0045] A. Preparation: Prepare the components that make up the polymer package strain gauge, including the strain gauge 2, the foil 3, and the polymer sealing plate 4, and mark the sensitive element positioning line on the foil 3;

[0046] B. Install the strain gauge: bond the strain gauge 2 on the foil 3 with the two-component epoxy resin adhesive H-610;

[0047] C. Install the polymer sealing plate: place the cavity of the polymer sealing plate 4 downward, align the cavity and cover the strain gauge 2, and then use the two-component epoxy resin adhesive on the bottom surface of the polymer sealing plate 4 H-610 is bonded to foil 3;

[0048] D. Glue filling: Fill the cavity of the polymer sealing plate 4 with the two-component epoxy resin adhesive H-610, and encapsulate the strain gauge 2 in the cavity of the poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com