Analysis method for internal holes of powder particles

A technology of internal pores and powder particles, applied in the field of analysis, can solve the problems of inability to accurately evaluate the porosity of particles, high preparation requirements, and limited magnification of the field of view.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

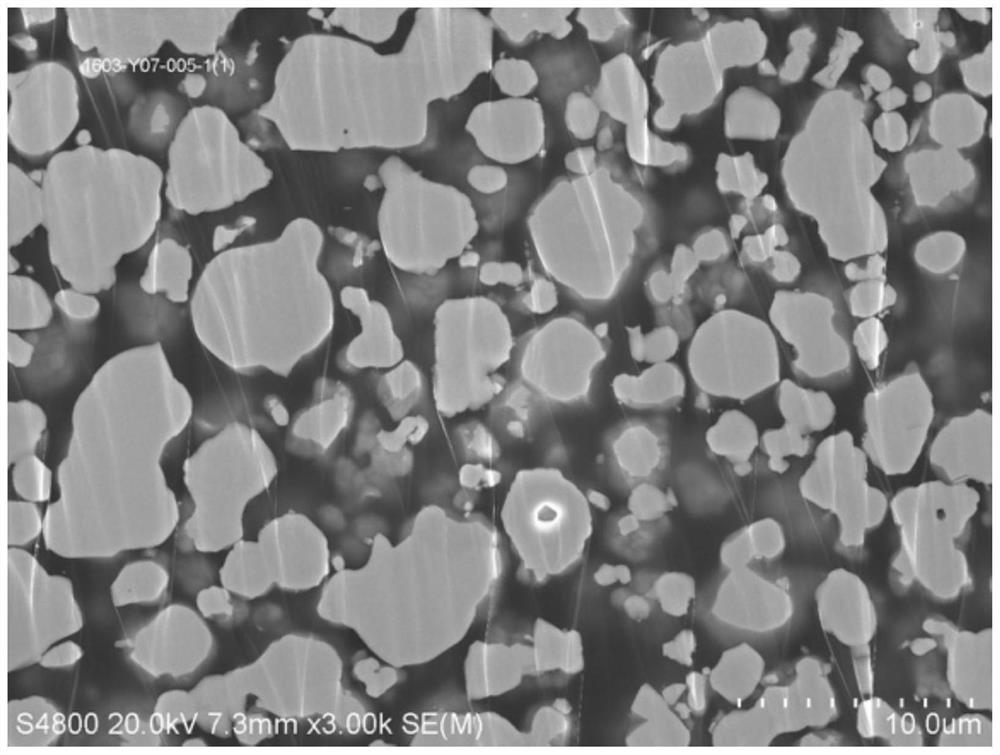

[0110] The present embodiment 1 provides a method for analyzing the internal pores of powder particles, comprising the following steps:

[0111] Step 11: Mix the embedding agent and the powder to be tested uniformly on the glass slide in a mass ratio of 2:1 to obtain a mixture.

[0112] Among them, the embedding agent is epoxy resin and epoxy resin curing agent with a mass ratio of 7:1. The bearing surface of the slide has a layer of Teflon tape.

[0113] Step 12: The mixture is placed in a molding die with a groove cavity, and pressed into shape to obtain a rectangular block sample with a size of 8mm*8mm*3mm, and a polytetrafluoroethylene tape layer is provided on the inner wall of the groove cavity.

[0114] Step 13: At a temperature of 130° C., heat curing the block sample for 20 minutes to obtain a cured sample.

[0115] Step 14: Determine the observation surface of the cured sample, perform pre-polishing treatment on the observation surface by conventional mechanical po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com