ZIF-8-derived lithium ion negative electrode material and preparation method thereof

A technology of ZIF-8 and negative electrode materials, which is applied in the direction of battery electrodes, electrochemical generators, structural parts, etc., can solve the problems of complex preparation methods, unsuitable for large-scale production, poor cycle stability, etc., and achieve rich sources and good Application prospect, effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

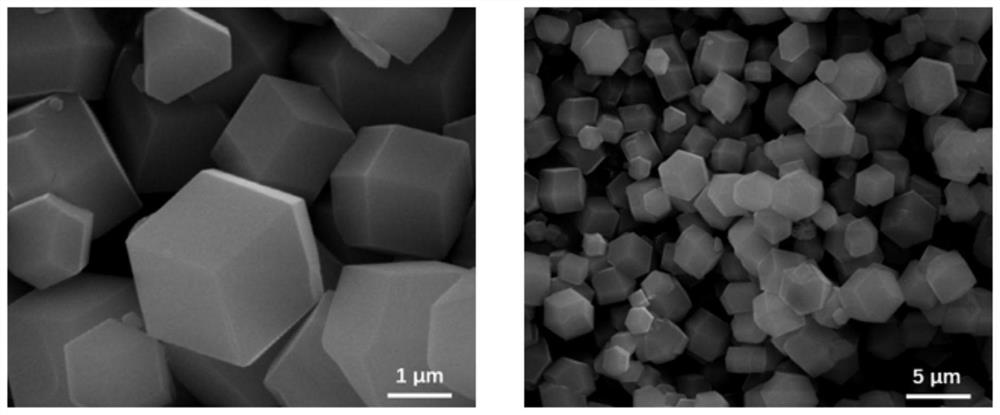

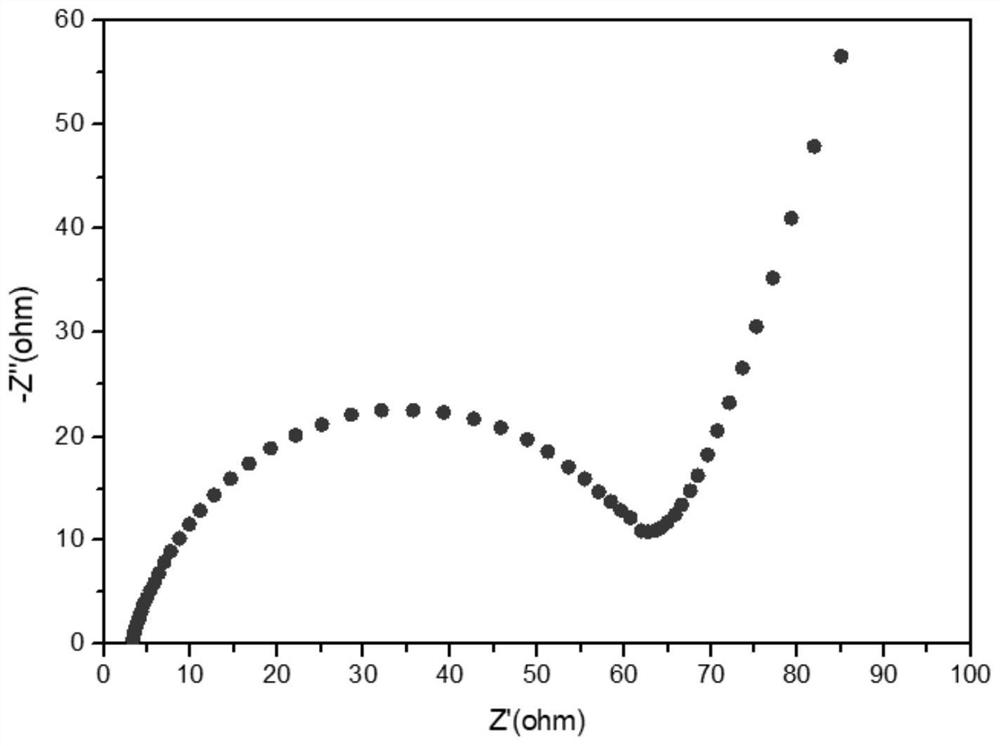

Embodiment 1

[0042] First measure 30ml of CH 3 OH solution and 150ml of deionized water were placed together in a 200ml beaker to form mixed solution A, and a magnetic stirrer was added to stir on a magnetic stirring table, and then 0.52g of Zn(NO) was weighed separately. 3 ) 2 ·6H 2 O and 0.72g of 2-methylimidazole were placed in a mortar, fully ground to make it evenly mixed, the mixed drug was slowly added to the mixed solution A and sonicated for 5 min under the action of an ultrasonic machine to fully dissolve the mixed drug to obtain a mixed solution. Solution B, the mixed solution B has become turbid (such as figure 1), then the mixed solution B was placed on a magnetic stirring table and stirred at a speed of 600 r / min for 8 h, and the obtained precipitate was centrifuged, filtered, and washed with CH 3 Wash it with OH solution 3 times, collect the precipitate after washing, put it in a vacuum drying box, and vacuum dry it at 60 °C for 12 h to obtain ZIF-8. Finally, put ZIF-8 in...

Embodiment 2

[0047] First measure 60ml of CH 3 OH solution and 180ml of deionized water were placed together in a 300ml beaker to form mixed solution A, and a magnetic stirring bar was added to stir on a magnetic stirring table, and then 1.04g of Zn(NO) was weighed separately. 3 ) 2 ·6H 2 O and 1.15g of 2-methylimidazole were placed in a mortar, fully ground to make it evenly mixed, the mixed drug was slowly added to the mixed solution A and sonicated for 5 min under the action of an ultrasonic machine, so that the mixed drug was fully dissolved to obtain a mixed solution. Solution B, the mixed solution B has become turbid (such as Image 6 ), then the mixed solution B was placed on a magnetic stirring table and stirred at a speed of 600 r / min for 8 h, and the obtained precipitate was centrifuged, filtered, and washed with CH 3 Wash it with OH solution 3 times, collect the precipitate after washing, put it in a vacuum drying box, and vacuum dry it at 60 °C for 12 h to obtain ZIF-8. Fina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com