Device and method for reducing underwater resistance of metal component through pulse laser

A metal component, pulsed laser technology, applied in the field of lasers, can solve the problems such as the anti-sea organism adhesion performance is not maintained for a long time, endangers human safety, pollutes the marine environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

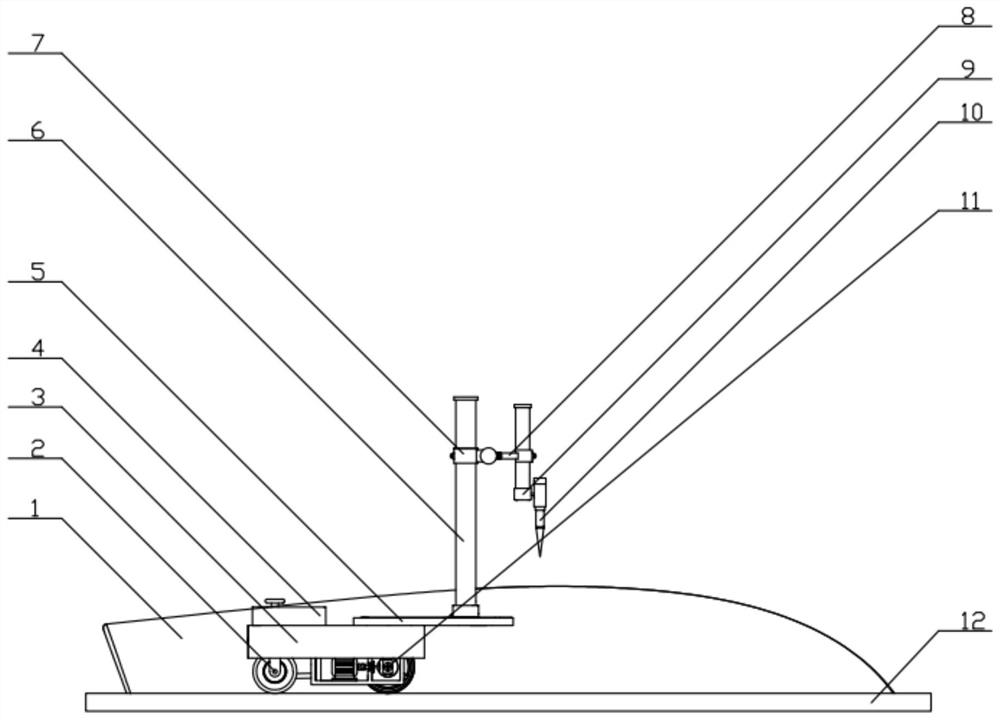

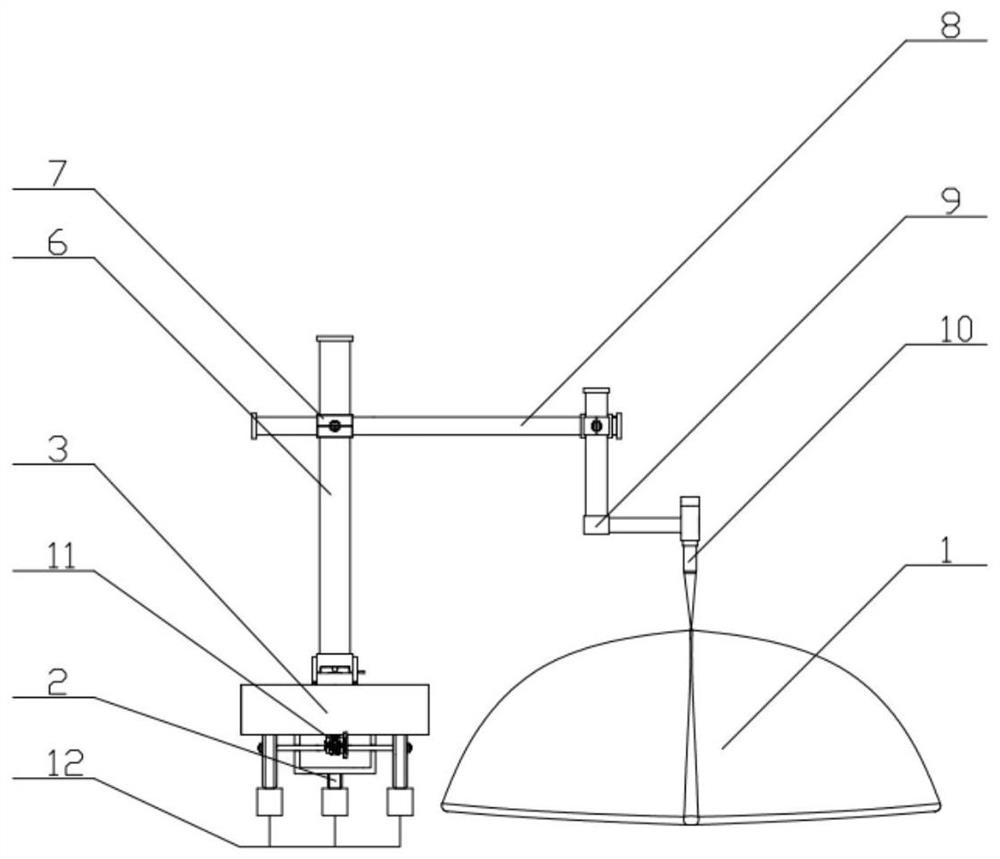

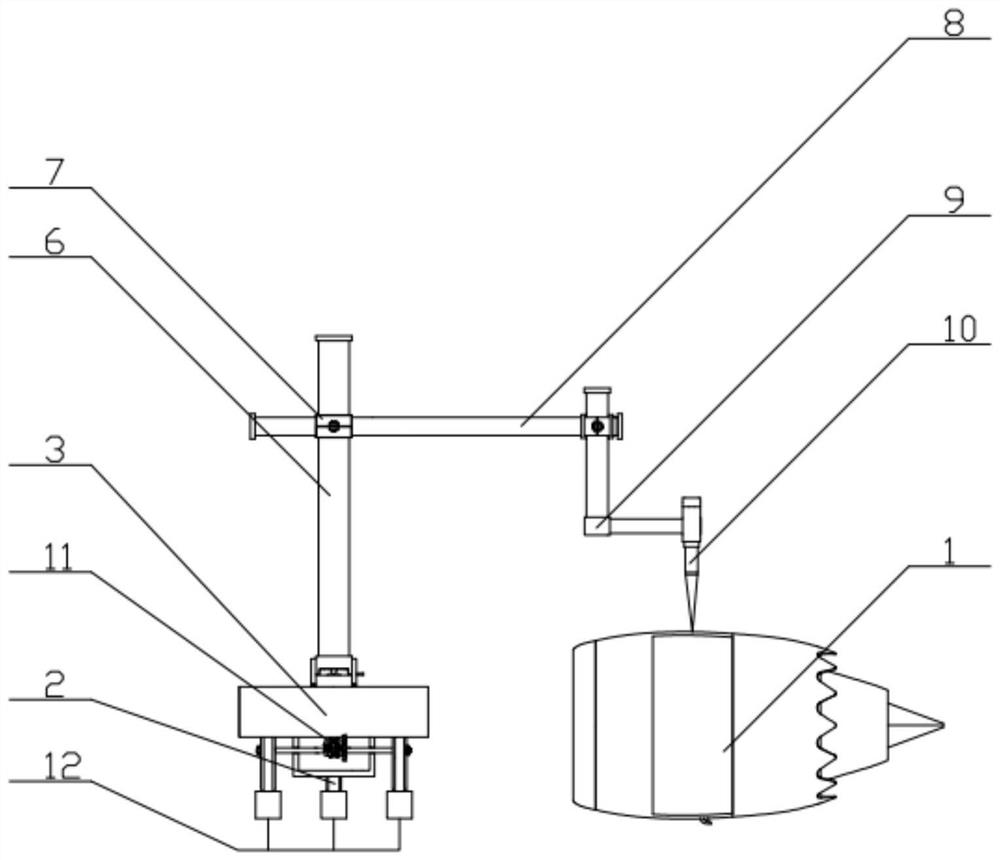

[0037] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples are only used to explain the present invention, but not to limit the scope of the present invention.

[0038] like figure 1 and figure 2 As shown, taking the hull as a metal metal component as an example, a device for reducing the underwater resistance of a metal component by using a pulsed laser is described. The device includes a traveling trolley 3 and a laser frame 6. On the surface of the track 12, a linear guide mechanism 5 is arranged on the walking trolley 3, the laser frame 6 is movably arranged on the linear guide mechanism 5, and the laser frame 6 can move along the linear guide mechanism 5, so The laser frame 6 is connected with a laser head 10 through a three-dimensional adjustment component, and the three-dimensional adjustment component can adjust the spatial posture of the laser head 10, so that the laser light emitted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com