Control method of visual welding process system

A technology of welding process and control method, applied in the control field of visual welding process system, can solve problems such as trouble, manual sorting by workers, inability to realize automatic intelligent control device, etc., and achieve the effect of ensuring consistency and fast service response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

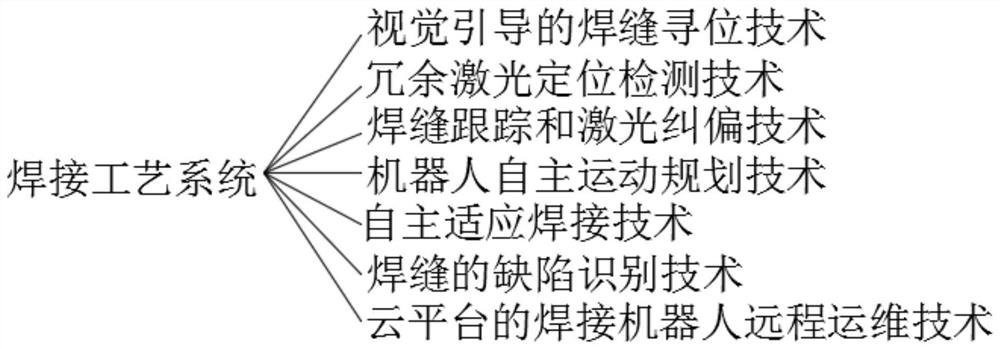

[0041] Embodiment 1: A control method for a visual welding process system, including vision-guided welding seam locating technology, redundant laser positioning detection technology, welding seam tracking and laser deviation correction technology, robot autonomous motion planning technology, autonomous adaptive welding technology and Weld defect identification technology;

[0042]Vision-guided welding seam locating technology, including visual image acquisition and preprocessing, welding seam identification, key point position coordinate calculation, welding seam teaching information and robot automatic path planning, through image processing of the weld seam image of the workpiece to be welded, Calculate the position coordinates of the start and end points of the welding seam to form the teaching information of the welding seam;

[0043] Redundant laser positioning detection technology, through the establishment of visual recognition and positioning algorithms based on deep l...

Embodiment 2

[0055] Embodiment 2: A control method for a visual welding process system, including vision-guided welding seam locating technology, redundant laser positioning detection technology, welding seam tracking and laser deviation correction technology, robot autonomous motion planning technology, autonomous adaptive welding technology and Weld defect identification technology;

[0056] Vision-guided welding seam locating technology, including visual image acquisition and preprocessing, welding seam identification, key point position coordinate calculation, welding seam teaching information and robot automatic path planning, through image processing of the weld seam image of the workpiece to be welded, Calculate the position coordinates of the start and end points of the welding seam to form the teaching information of the welding seam;

[0057] Redundant laser positioning detection technology, through the establishment of visual recognition and positioning algorithms based on deep ...

Embodiment 3

[0066] Embodiment 3: A control method for a visual welding process system, including vision-guided welding seam locating technology, redundant laser positioning detection technology, welding seam tracking and laser deviation correction technology, robot autonomous motion planning technology, autonomous adaptive welding technology and Weld defect identification technology;

[0067] Vision-guided welding seam locating technology, including visual image acquisition and preprocessing, welding seam identification, key point position coordinate calculation, welding seam teaching information and robot automatic path planning, through image processing of the weld seam image of the workpiece to be welded, Calculate the position coordinates of the start and end points of the welding seam to form the teaching information of the welding seam;

[0068] Redundant laser positioning detection technology, through the establishment of visual recognition and positioning algorithms based on deep ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com