Method for integrating composite material structure with optical fiber

A composite material and optical fiber technology, applied in optical components, household appliances, weight reduction, etc., can solve problems affecting structural strength performance, limiting optical fiber sensing engineering applications, easy degumming or damage, etc., to increase strain transfer efficiency, Good market prospects and remarkable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

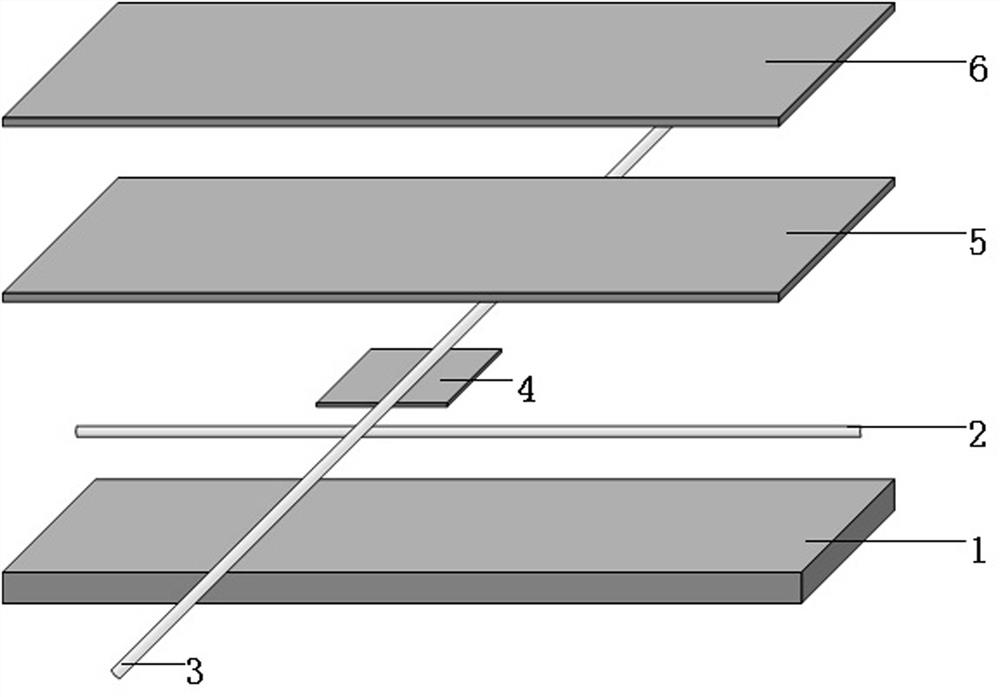

[0029] This embodiment provides a method for integrating an optical fiber with a composite material structure. The specific structure of the integrated optical fiber is as follows: figure 1 As shown, the specific process includes the following steps:

[0030] (1) Preparation of composite structure 1 composed of prepreg;

[0031] (2) Pretreatment of composite structure 1;

[0032] (3) Select an optical fiber with a high temperature resistant coating as the sensor, use glue to temporarily fix the optical fiber, and lay it on the surface of the composite structure 1 according to the layout design, where the optical fibers intersect, cut a piece that is the same as that used in the composite structure 1. The small prepreg 4 is placed at the intersection of the upper optical fiber 2 and the lower optical fiber 3 to avoid the high voltage breaking the optical fiber;

[0033] (4) Cover the adhesive film 5 on the temporarily fixed optical fiber;

[0034] (5) Use a heating device to...

Embodiment 2

[0038] On the basis of the above-mentioned embodiments, this embodiment further defines the specific process of step (1). In the step (1), the specific preparation process of the composite structure is to use prepregs to lay up and then solidify under high temperature and high pressure. The method prepares a composite structure. The other parts of this embodiment are the same as the above-mentioned embodiments, and are not repeated here.

Embodiment 3

[0040] On the basis of the above-mentioned embodiment, this embodiment further defines the specific process of step (2). In the step (2), the preprocessing process of the composite material structure is as follows: the side of the composite material structure on which the optical fiber is to be laid is carried out. Clean and sanded. The other parts of this embodiment are the same as the above-mentioned embodiments, and are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com