Preparation method of optical lithium metaphosphate

A lithium metaphosphate, optical-grade technology, applied in the field of optical glass raw material metaphosphate chemical industry, can solve the problems of high purity of lithium metaphosphate, insufficient removal effect of Fe and Cu ions, and high removal cost, and achieve high purity and reduce solids. The effect of knot phenomenon and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

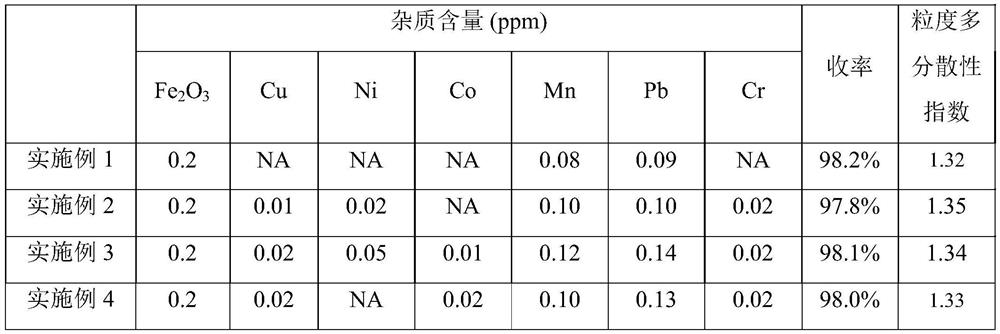

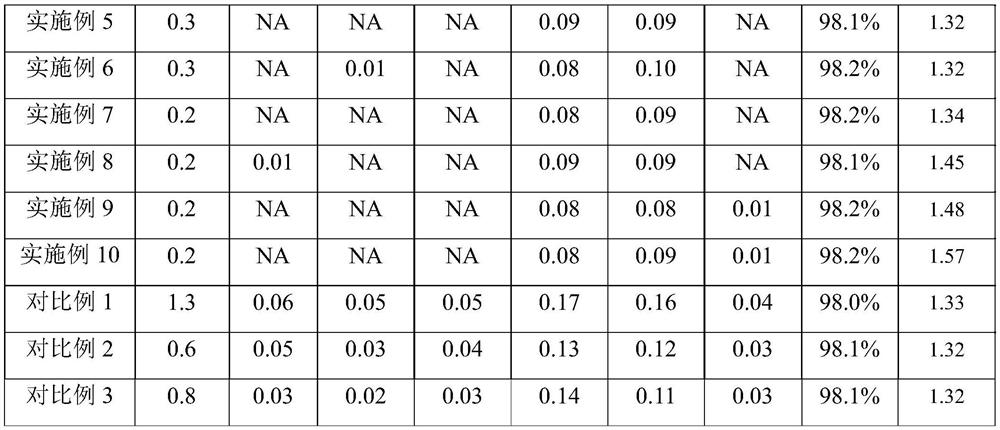

Examples

preparation example 1

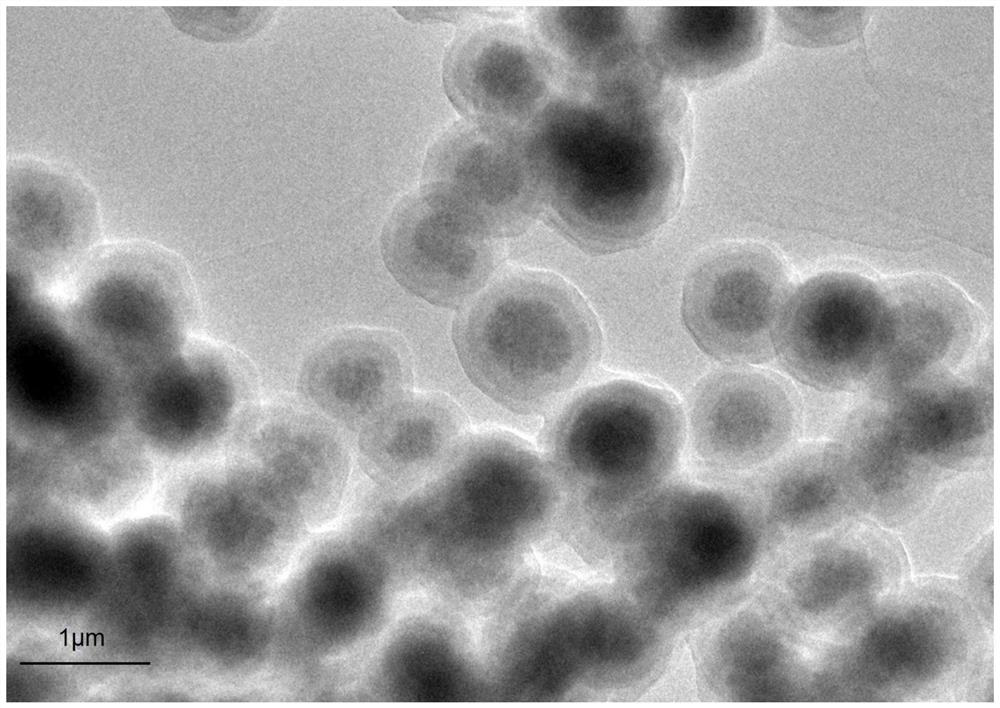

[0036] (S1) 10 parts of tetraethyl orthosilicate are added to 90% ethanol aqueous solution, after uniform dispersion, 2 parts of 23.5% ammonia water are added, and the reaction is carried out at 30°C for 6 hours under stirring conditions, and separated by a high-speed refrigerated centrifuge at 10,000 rpm. The obtained silica particles were extracted, vortexed and sonicated to remove impurities, and washed alternately with absolute ethanol and deionized water for 3 times to obtain SiO as a growth nucleus. 2 particle.

[0037] (S2) Add 0.3 parts of SiO obtained in step (S1) to deionized water 2 Microparticles were used as growth nucleus, 1.2 parts of P123 and 1.2 parts of PEG2000 were used as template agents, stirred at a constant temperature of 35 °C for 1 h, added 6 parts of tetraethyl orthosilicate, maintained at 35 °C and continued to stir for 6 h, stood at room temperature for 24 h, poured out the supernatant, The white precipitate was washed three times alternately with ...

preparation example 2

[0042] Other conditions are the same as in Preparation Example 1, except that the template agent in step (S2) is 1.6 parts of P123 and 0.8 parts of PEG1000.

preparation example 3

[0044] Other conditions are the same as in Preparation Example 1, except that the template agent in step (S2) is 2.4 parts of P123.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com