High-dielectric low-loss doped barium calcium titanate ceramic and preparation method thereof

A technology of barium calcium titanate and dielectric loss, applied in the field of high dielectric low loss doped barium calcium titanate ceramics and its preparation, to achieve the effect of improving dielectric temperature stability and great application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

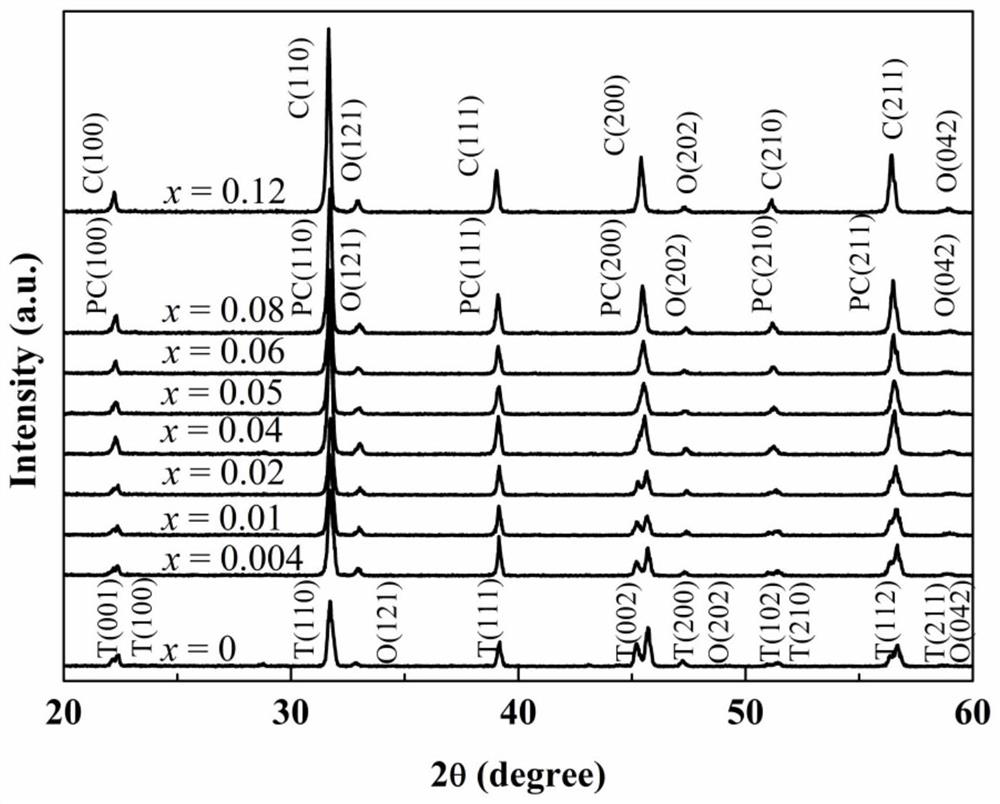

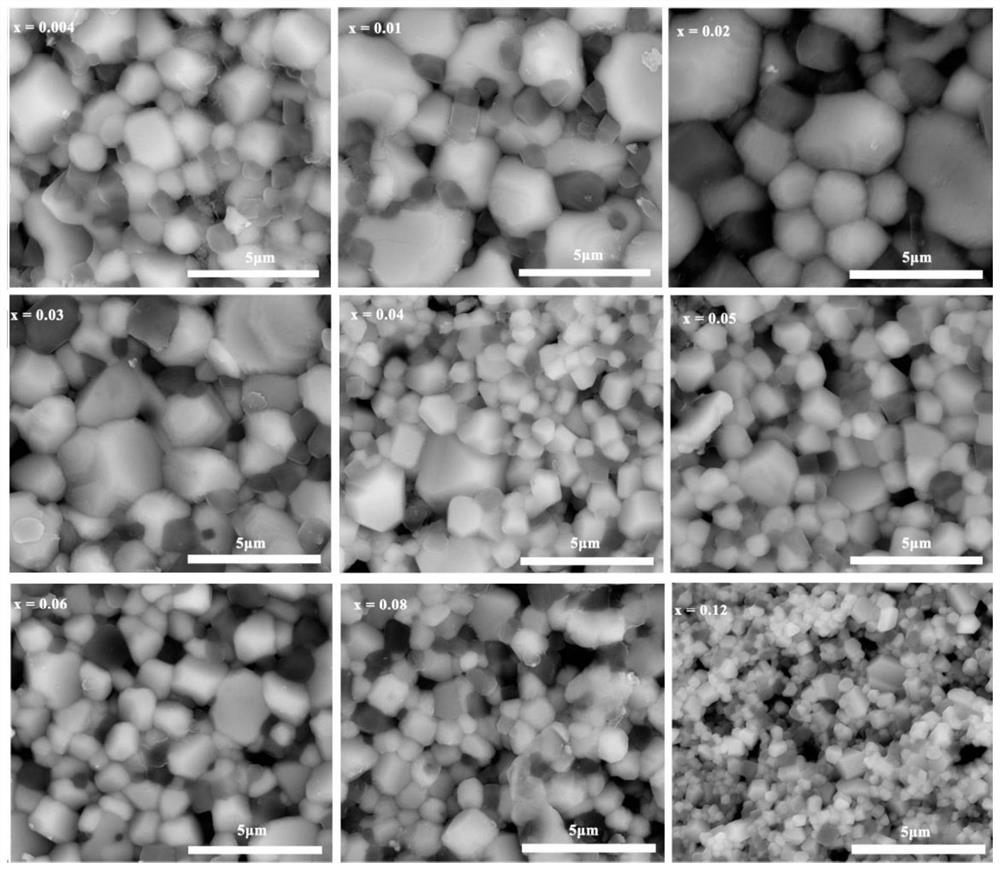

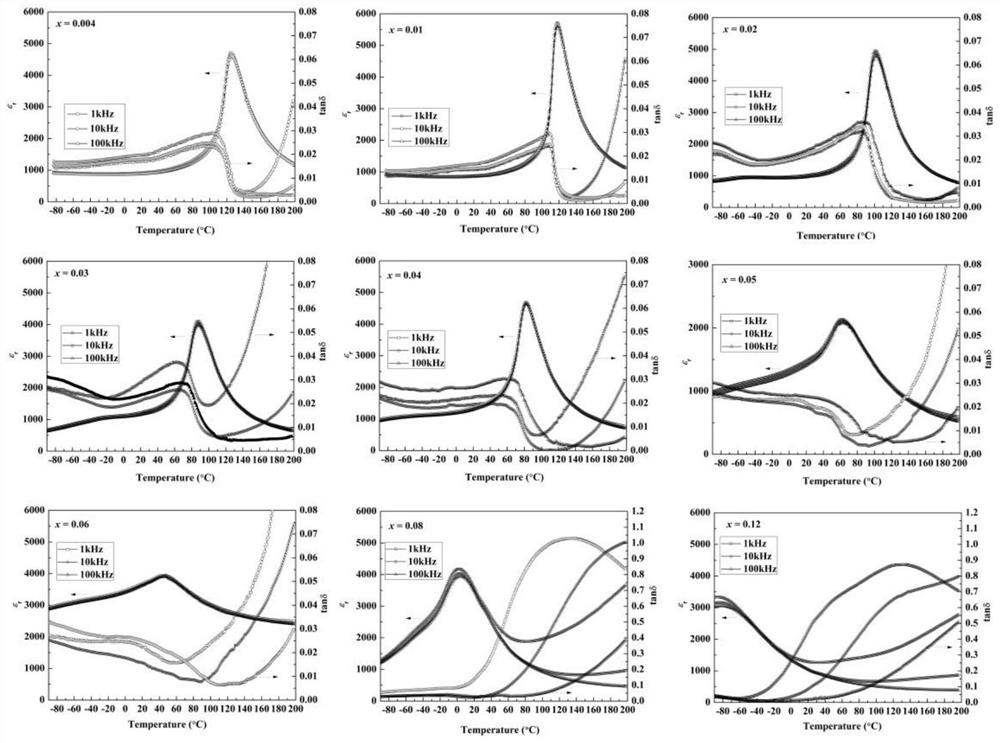

[0018] Embodiment 1: The chemical formula of a high-dielectric and low-loss doped barium-calcium titanate ceramic in this embodiment is Ba 0.70 Ca 0.30 Ti 1-x (Nb 0.5 Fe 0.5 ) x O 3 , where x is in the compound (Nb 0.5 Fe 0.5 ) 4+ The mole ratio, 0.04≤x≤0.06.

specific Embodiment approach 2

[0019] Specific embodiment 2: The preparation method of a high dielectric and low loss doped barium calcium titanate ceramic in this embodiment is carried out according to the following steps:

[0020] (1) According to the chemical composition Ba 0.70 Ca 0.30 Ti 1-x (Nb 0.5 Fe 0.5 ) x O 3 The stoichiometric ratio of the analytically pure grade pharmaceutical powder BaCO 3 , CaCO 3 , TiO 2 , Fe 2 O 3 and 98% pure MnO 2 Powder, of which 0.04≤x≤0.06, mix the weighed powder, put it into anhydrous ethanol medium, use agate grinding ball as the ball milling medium, and use a planetary ball mill to wet ball mill at a speed of 150-175 r / min for 20 Mix evenly for ~24h, wherein the ratio of the mass of the anhydrous ethanol medium to the total mass of the powder is (1.1~1.5):1; the grinding balls used are made of agate balls with diameters of 20mm, 10mm and 6mm according to the number ratio of 1:11 : 16 compositions, drying slurry;

[0021] (2) adding the deionized water of...

specific Embodiment approach 3

[0025] Embodiment 3: This embodiment differs from Embodiment 2 in that: in step (1), x=0.06, and x=0.08. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com