A kind of perovskite structure nano ceramic material and preparation method thereof

A perovskite structure and nano-ceramic technology, applied in the field of nano-ceramics, can solve the problems of poor dielectric temperature stability and large environmental pollution, and achieve the effects of high dielectric constant, no environmental pollution, and improved dielectric properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] Another aspect of the present application provides a method for preparing a perovskite-structured nano-ceramic material, comprising the following steps:

[0045] S1 prepares a solution containing A, A', B and B' according to a preset ratio;

[0046] S2 adds an alkaline solution to the solution, adjusts the pH value of the solution to alkaline, and continues the reaction until the solid is separated out;

[0047] S3 separates the solid to obtain a precursor;

[0048] S4 roasts the precursor at high temperature to obtain a nano-ceramic material;

[0049] in,

[0050] Said A and said A' are selected from La, Ce, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu;

[0051]The B and the B' are selected from Co, Fe, Ni, Mn, Cr, Cu.

[0052] In order to clearly illustrate the present invention, the experimental procedures of steps S1-S4 are described in detail below respectively.

[0053] In the described step S1, the preset proportioning refers to the ABO to be prepared ...

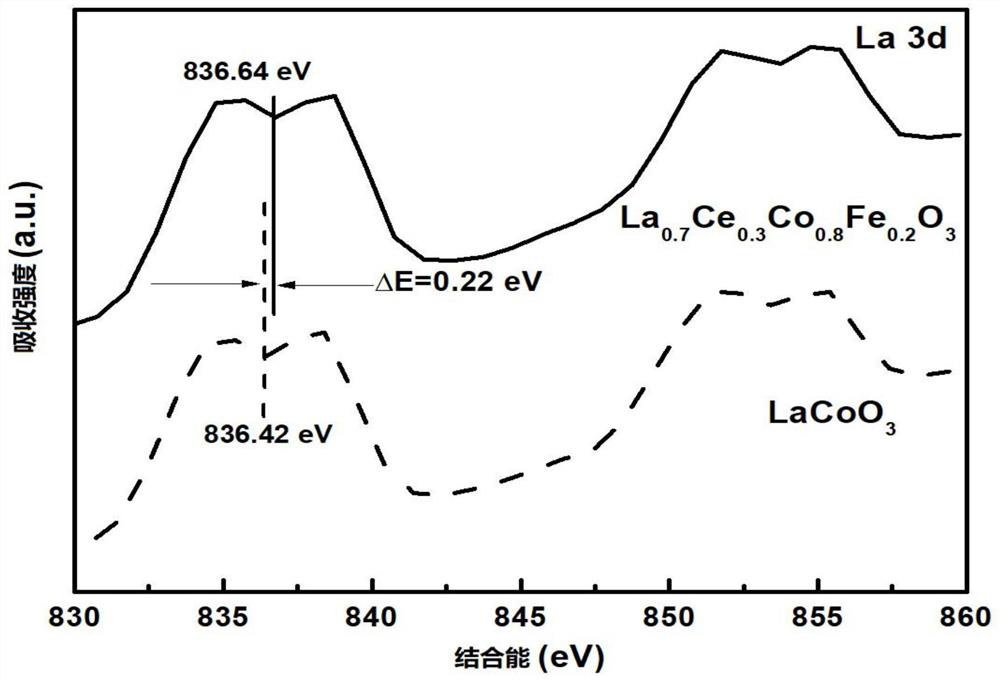

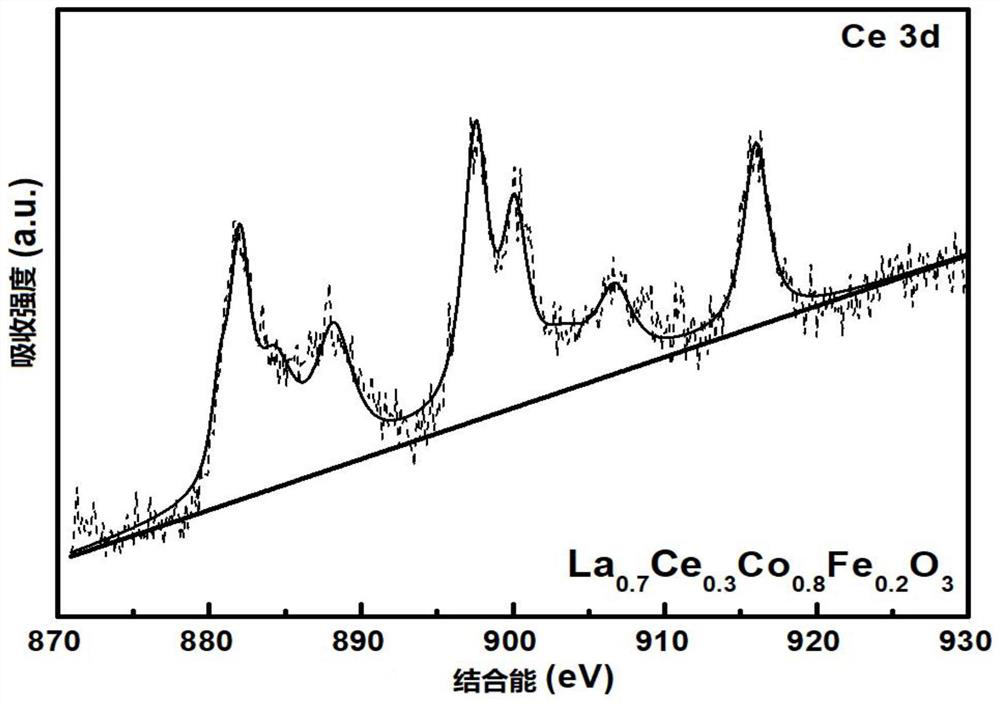

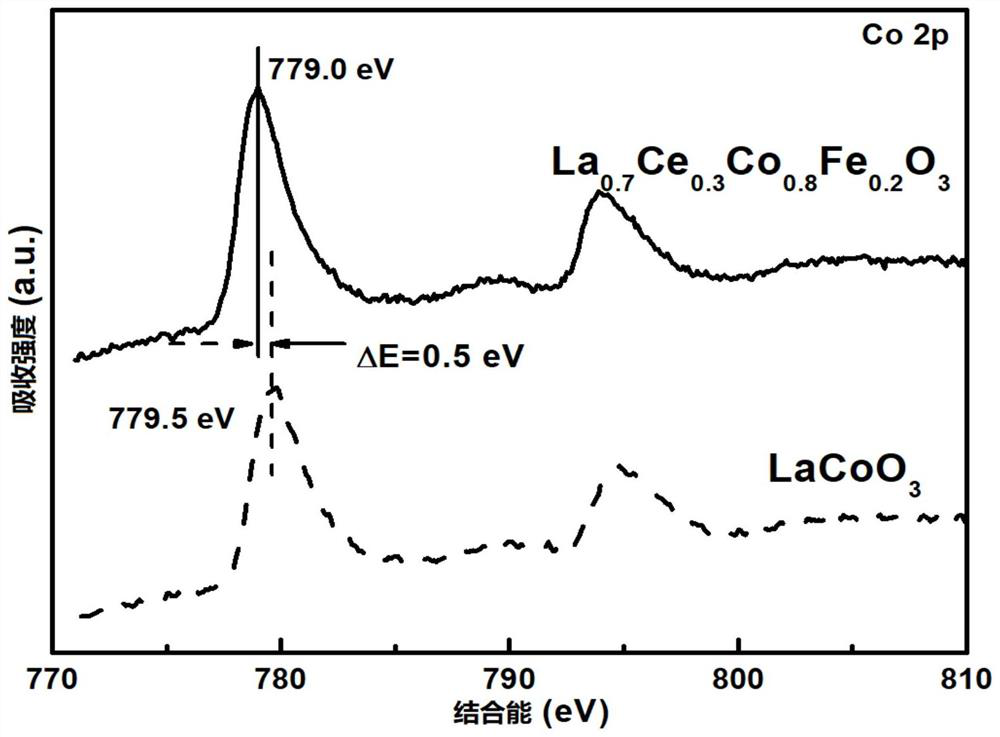

Embodiment 1

[0060] S1 Dissolve cobalt sulfate, iron sulfate, lanthanum sulfate and cerium sulfate in deionized water, ultrasonicate for 10 minutes, and stir for 1 hour until a homogeneous solution is formed, wherein, calculated in molar ratio, cobalt sulfate: iron sulfate: lanthanum sulfate: cerium sulfate is 0.8:0.2:0.7:0.3.

[0061] S2 was added dropwise a sodium carbonate solution with a concentration of 1 mol / L into the solution to make the pH of the solution=10, and the solution was continuously stirred on a magnetic stirrer for 2 hours until the solid substance was fully separated.

[0062] S3 Centrifuge the reaction solution obtained in step S1 for 5 min at a rotating speed of 8000 rpm, and analyze to obtain a solid product. The mixed solution of ethanol and deionized water is used to centrifuge and wash the product for 3 times, and it is dried at 60 °C for 12 h to obtain hydrogen. oxide precursor.

[0063] S4 The precursor prepared in step S3 is placed in a tube furnace, and calc...

Embodiment 2

[0065] S1 Dissolve cobalt sulfate, nickel sulfate, lanthanum sulfate and cerium sulfate in deionized water, ultrasonicate for 10 minutes, and stir for 1 hour until a homogeneous solution is formed, wherein, calculated in molar ratio, cobalt sulfate: nickel sulfate: lanthanum sulfate: cerium sulfate is 0.8:0.2:0.7:0.3.

[0066] S2 was added dropwise a sodium carbonate solution with a concentration of 1 mol / L into the solution to make the pH of the solution=10, and the solution was continuously stirred on a magnetic stirrer for 2 hours until the solid substance was fully separated.

[0067] S3 Centrifuge the reaction solution obtained in step S1 for 5 min at a rotating speed of 8000 rpm, and analyze to obtain a solid product. The mixed solution of ethanol and deionized water is used to centrifuge and wash the product for 3 times, and it is dried at 60 °C for 12 h to obtain hydrogen. oxide precursor.

[0068] S4 The precursor prepared in step S3 is placed in a tube furnace, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com