Antibacterial odor-removing super absorbent resin and preparation method thereof

A super absorbent resin and odor technology, which is used in absorbent pads, resistance to vector-borne diseases, bandages, etc., can solve the problems of difficult preparation of super absorbent resin, complex raw material composition and content, and high process conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

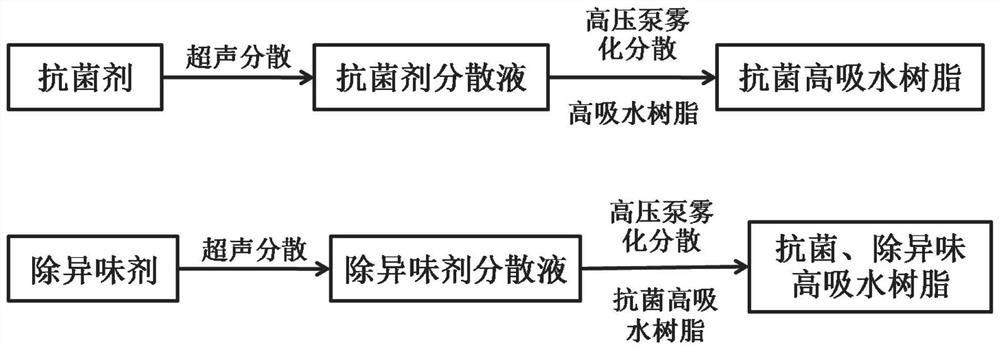

[0083] The invention provides a preparation method of an antibacterial and deodorant superabsorbent resin composite material, comprising the following steps:

[0084] 1) The antibacterial material aqueous dispersion obtained after ultrasonic dispersion is compounded on the superabsorbent resin by atomization, and after drying, an intermediate product is obtained;

[0085] 2) The deodorant material aqueous dispersion obtained after ultrasonic dispersion is again atomized and compounded on the intermediate product obtained in the above step, and after drying, an antibacterial deodorant superabsorbent resin compound material is obtained.

[0086] In the present invention, the antibacterial material aqueous dispersion obtained after ultrasonic dispersion is firstly compounded on the superabsorbent resin by atomization, and the intermediate product is obtained after drying.

[0087] In the present invention, the temperature of the ultrasonic dispersion is preferably 25-50°C, more p...

Embodiment 1

[0136] Preparation of Polyhexanide Hydrochloride / 4-Ethyl-4-Soybean Ethyl Sulfate Morpholine Composite Antibacterial and Deodorant Super Absorbent Resin

[0137] Accurately measure 100g of polyhexanide hydrochloride phase dispersion with a concentration of 5.0%, put it into the storage tank of the high-pressure pump, set the pressure of the high-pressure pump to 0.3MPa, and evenly spray it in 10 batches. The surface of 495g super absorbent resin beads at rev / min was stirred and mixed, and the prepared polyhexanide hydrochloride antibacterial super absorbent resin was collected and placed in a 50° C. oven for drying treatment for 24 hours to obtain a dry product. Then accurately measure 100g of 4-ethyl 4-soy ethyl sulfate morpholine aqueous phase dispersion with a concentration of 1.0%, put it into the storage tank of the high-pressure pump, set the pressure of the high-pressure pump to 0.5MPa, divide it into 10 batches It is uniformly sprayed and dispersed on the surface of the...

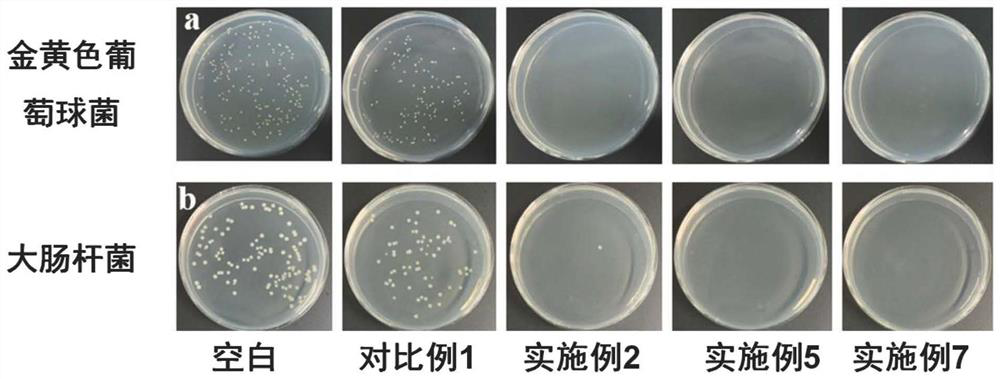

Embodiment 2

[0141] Preparation of polyhexanide hydrochloride / zinc ricinoleate composite antibacterial and deodorant superabsorbent resin

[0142]Accurately measure 100g of polyhexanide hydrochloride phase dispersion with a concentration of 5.0%, put it into the storage tank of the high-pressure pump, set the pressure of the high-pressure pump to 0.6MPa, and evenly spray it in 10 batches. The surface of 495g super absorbent resin beads at rev / min was stirred and mixed, and the prepared polyhexanide hydrochloride antibacterial super absorbent resin was collected and placed in a 50° C. oven for drying treatment for 24 hours to obtain a dry product. Then accurately measure 100g of zinc ricinoleate aqueous phase dispersion with a concentration of 3.0%, put it into the storage tank of the high-pressure pump, set the pressure of the high-pressure pump to 0.7MPa, and evenly spray and disperse it in 10 batches with the stirring speed of 100. The surface of the antibacterial super absorbent resin b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com