Preparation method and use method of waterborne epoxy primer for automobile aftermarket

A water-based epoxy technology in the automotive aftermarket, applied in the direction of epoxy resin coatings, coatings, anti-corrosion coatings, etc., can solve the problems of less anti-corrosion epoxy primer, low performance requirements of coating process, and slow drying speed , to achieve the effects of improved anti-flash embroidery performance, high adhesion, and improved drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

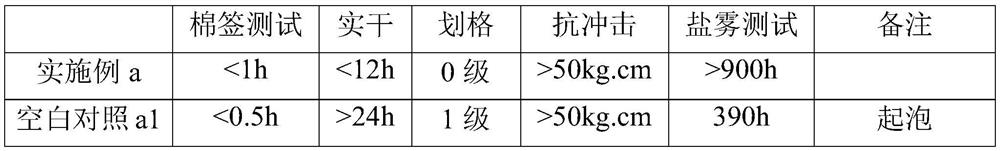

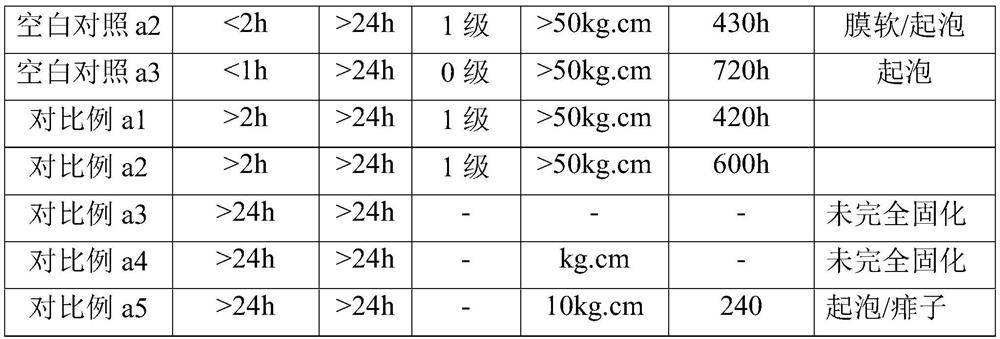

Examples

preparation example Construction

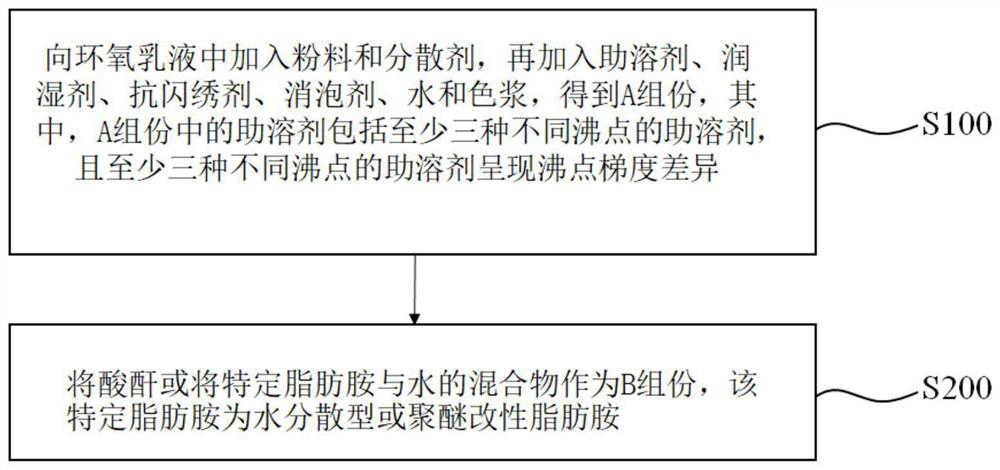

[0035] figure 1 A schematic flow chart of a method for preparing a water-based epoxy primer for the automotive aftermarket according to an embodiment of the present invention is shown. like figure 1 As shown, the preparation method includes:

[0036] Step S100, adding powder and dispersant to the epoxy emulsion, then adding cosolvent, wetting agent, anti-flash embroidery agent, defoaming agent, water and color paste to obtain component A, wherein the The co-solvents include at least three co-solvents with different boiling points, and the at least three co-solvents with different boiling points exhibit differences in boiling points;

[0037] In step S200, an acid anhydride or a mixture of a specific aliphatic amine and water is used as the B component, and the specific aliphatic amine is a water-dispersed or polyether-modified aliphatic amine.

[0038] According to the solution of the embodiment of the present invention, the A component includes epoxy emulsion, powder, coso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com