Green composite CIP cleaning agent as well as preparation method and use method thereof

A cleaning agent, green technology, applied in the direction of detergent compounding agent, chemical equipment and method, detergent composition, etc., can solve the problems of long cleaning process, high cost, non-compliance with green cleaning standards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

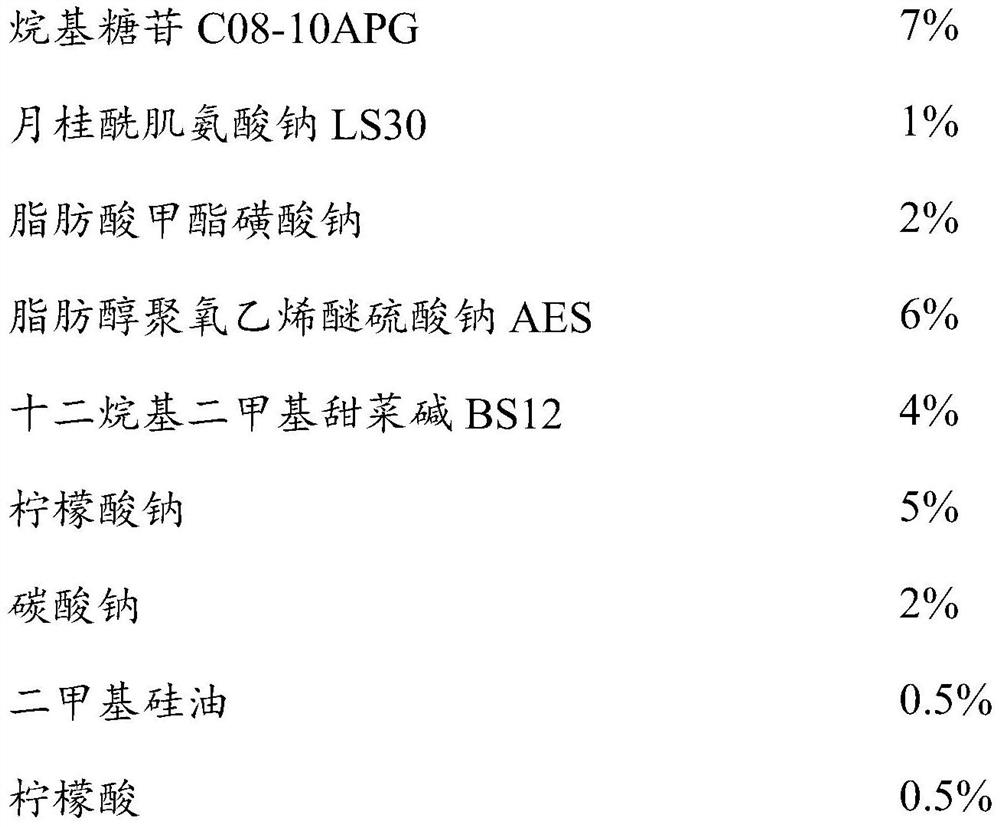

[0021] A green composite CIP cleaning agent is prepared from the following raw materials by weight percentage:

[0022]

[0023]

[0024] The preparation method of the green composite CIP cleaning agent described in embodiment 1, comprises the steps:

[0025] S1: Weigh 7% alkyl glycoside C08-10APG, 1% sodium lauroyl sarcosinate LS30, 2% sodium fatty acid methyl ester sulfonate, 6% fatty alcohol polyoxyethylene ether sulfate sodium AES, 4% by weight percentage respectively Dodecyl dimethyl betaine BS12, 5% sodium citrate, 2% sodium carbonate, 0.5% dimethicone, 0.5% citric acid, 2% methylisothiazolinone and deionized water;

[0026] S2: Heat part of deionized water to a constant temperature of 60-70 °C, add sodium carbonate and sodium citrate and stir until completely dissolved, then add alkyl glycoside C08-10APG, sodium fatty acid methyl ester sulfonate, and sodium lauroyl sarcosinate in turn LS30, fatty alcohol polyoxyethylene ether sodium sulfate AES, dodecyl dimethyl ...

Embodiment 2

[0029] A green composite CIP cleaning agent is prepared from the following raw materials by weight percentage:

[0030]

[0031]

[0032] The preparation method of the green composite CIP cleaning agent described in embodiment 2, comprises the steps:

[0033] S1: Weigh 8% alkyl glycoside C08-10APG, 2% sodium lauroyl sarcosinate LS30, 2% sodium fatty acid methyl ester sulfonate, 6% fatty alcohol polyoxyethylene ether sulfate sodium AES, 5% by weight percentage respectively Dodecyldimethylbetaine BS12, 1% EDTA-2Na, 2% sodium carbonate, 0.4% dimethicone, 0.3% citric acid, 1% methylisothiazolinone and deionized water;

[0034] S2: Heat part of the deionized water to a constant temperature of 60-70 °C, add sodium carbonate and EDTA-2Na and stir until the dissolution is complete, then add alkyl glycoside C08-10APG, sodium fatty acid methyl ester sulfonate, and sodium lauroyl sarcosinate in turn LS30, fatty alcohol polyoxyethylene ether sodium sulfate AES, dodecyl dimethyl bet...

Embodiment 3

[0037] A green composite CIP cleaning agent is prepared from the following raw materials by weight percentage:

[0038]

[0039]

[0040] The preparation method of the green composite CIP cleaning agent described in embodiment 3, comprises the steps:

[0041] S1: weigh 6% alkyl glycoside C08-10APG, 3% sodium lauroyl sarcosinate LS30, 2% sodium fatty acid methyl ester sulfonate, 6% fatty alcohol polyoxyethylene ether sulfate sodium AES, 3% by weight percentage respectively Dodecyl dimethyl betaine BS12, 2% sodium citrate, 2% EDTA-2Na, 2% sodium carbonate, 0.4% dimethicone, 0.5% citric acid, 2% methylisothiazolinone and ionized water;

[0042] S2: heat part of deionized water to a constant temperature of 60-70 °C, add sodium carbonate, sodium citrate and EDTA-2Na and stir until it is completely dissolved, then add alkyl glycoside C08-10APG, sodium fatty acid methyl ester sulfonate, lauroyl in turn Sodium sarcosinate LS30, fatty alcohol polyoxyethylene ether sulfate sodiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com