Negative electrode and preparation method and application thereof

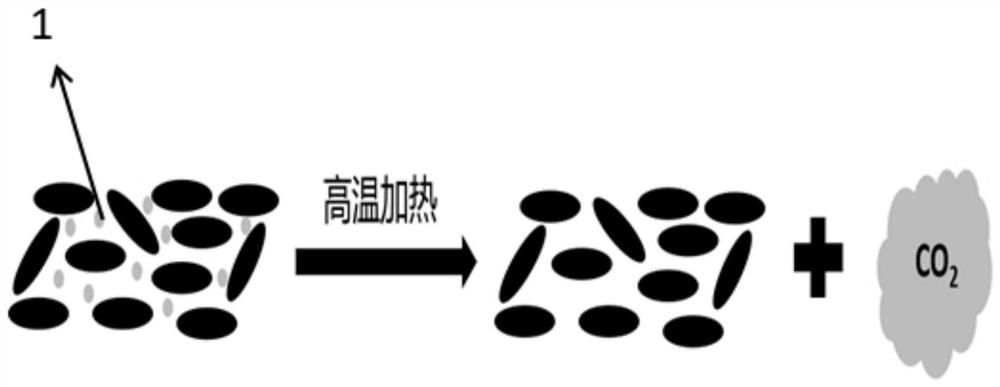

A negative electrode and negative electrode active technology, applied in the direction of battery electrodes, structural parts, electrical components, etc., can solve the problems of ineffective control of thermal runaway, slow release speed of flame retardants, slow reaction speed, etc., to curb the generation and spread of open flames , reduce the risk, delay the effect of the fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

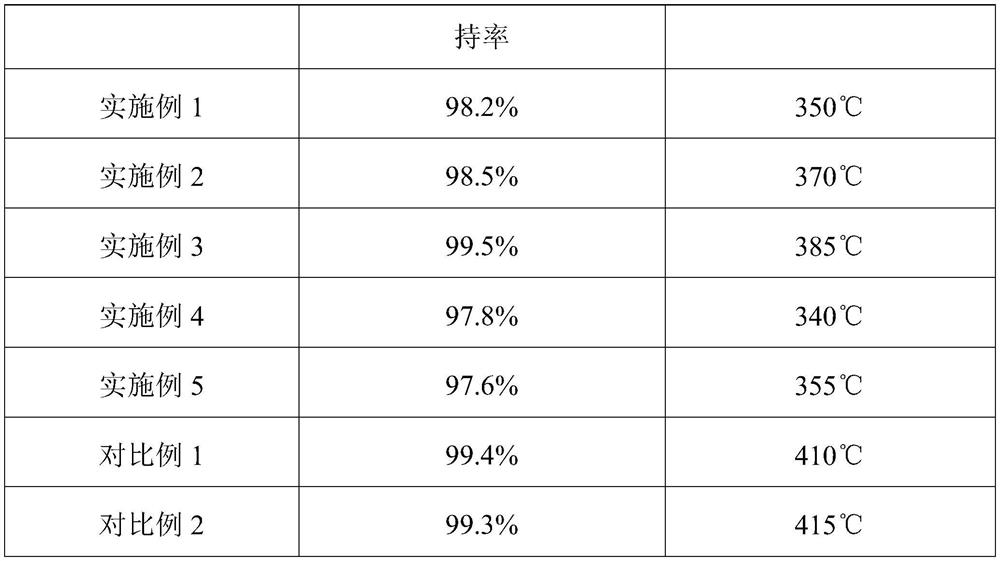

Embodiment 1

[0052] This embodiment provides a negative electrode, the negative electrode is composed of copper foil and negative electrode active layers located on both sides of the copper foil; the negative electrode active layer includes artificial graphite, thermal initiator, hydroxymethyl cellulose (CMC), styrene-butadiene rubber ( SBR) and conductive carbon black (SP) (mass ratio 83:10:2:2:3);

[0053] Among them, the thermal initiator is a carbon material obtained by carbonizing polystyrene at 350° C., D50 is 1 μm, and D50 of artificial graphite is 15 μm.

[0054] The preparation method of the negative electrode is as follows:

[0055] (1) Disperse the thermal initiator in N-methylpyrrolidone (NMP), place the dispersed solution in a closed container under the condition of stirring in a water bath at 45°C, and mix it well by stirring for 3 hours to obtain a dispersed solution. At the same time, artificial graphite, CMC, SBR and SP are mixed with water to obtain mixed slurry (guarant...

Embodiment 2

[0059] This embodiment provides a negative electrode, the negative electrode is composed of copper foil and negative electrode active layers located on both sides of the copper foil; the negative electrode active layer includes hard carbon, thermal initiator, hydroxymethyl cellulose (CMC), styrene-butadiene rubber ( SBR) and conductive carbon black (SP) (mass ratio is 88:5:2:2:3);

[0060] Among them, the thermal initiator is a carbon material obtained by carbonizing polystyrene at 400° C., D50 is 500 nm, and D50 of hard carbon is 8 μm.

[0061] The preparation method of the negative electrode is as follows:

[0062] (1) Disperse the thermal initiator in N-methylpyrrolidone (NMP), place the dispersed solution in a closed container under the condition of stirring in a water bath at 45°C, and mix it well by stirring for 3 hours to obtain a dispersed solution. liquid; at the same time, hard carbon, thermal initiator, hydroxymethyl cellulose (CMC), styrene-butadiene rubber (SBR) ...

Embodiment 3

[0065] This embodiment provides a negative electrode, the negative electrode is composed of copper foil and negative electrode active layers located on both sides of the copper foil; the negative electrode active layer includes artificial graphite, thermal initiator, hydroxymethyl cellulose (CMC), styrene-butadiene rubber ( SBR) and conductive carbon black (SP) (mass ratio of 91:2:2:2:3);

[0066] Among them, the thermal initiator is a carbon material obtained by carbonizing polystyrene at 350° C., D50 is 1 μm, and D50 of artificial graphite is 5 μm.

[0067] The preparation method of the negative electrode is as follows:

[0068] (1) Disperse the thermal initiator in N-methylpyrrolidone (NMP), place the dispersed solution in a closed container under the condition of stirring in a water bath at 45°C, and mix it well by stirring for 3 hours to obtain a dispersed solution. At the same time, artificial graphite, SBR and SP are mixed with water to obtain mixed slurry (guaranteed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com