Positive pole piece and lithium ion battery

A technology of lithium ion batteries and positive electrode pieces, which is applied in the manufacture of battery electrodes, secondary batteries, electrolyte batteries, etc., can solve problems such as the inability to balance energy density and safety performance, and achieves improved nail penetration safety performance, guaranteed energy density, The effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation of the lithium ion battery is described below, and the preparation method includes: preparation of positive pole piece, preparation of negative pole piece, preparation of electrolyte, preparation of separator and preparation of lithium ion battery, and specifically includes the following steps:

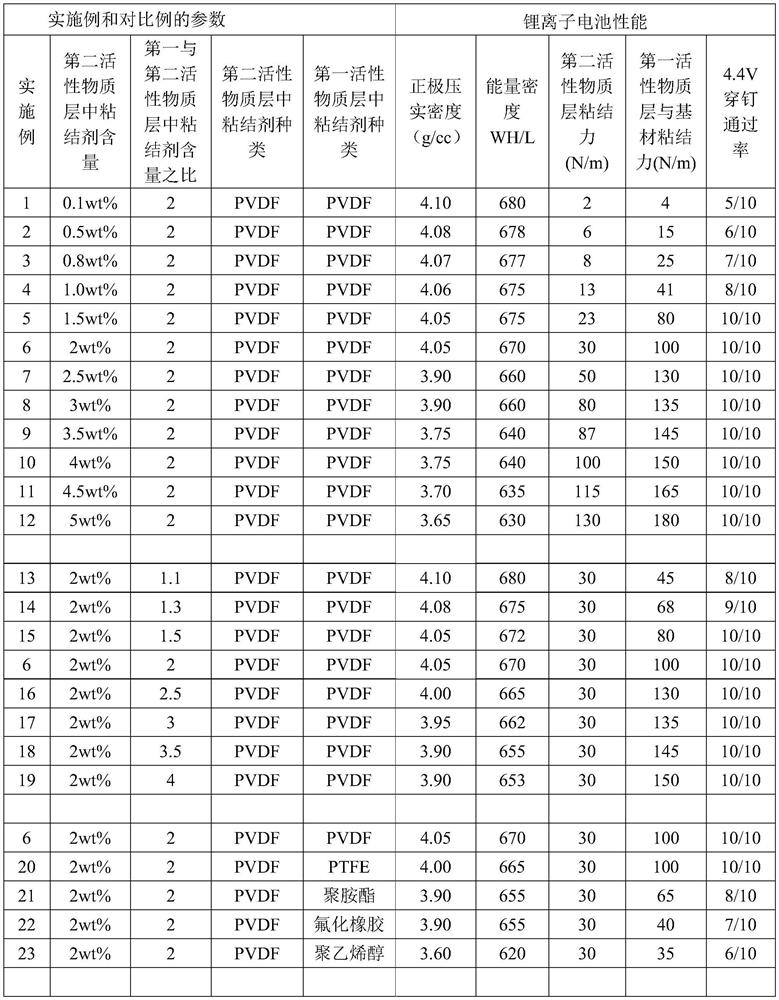

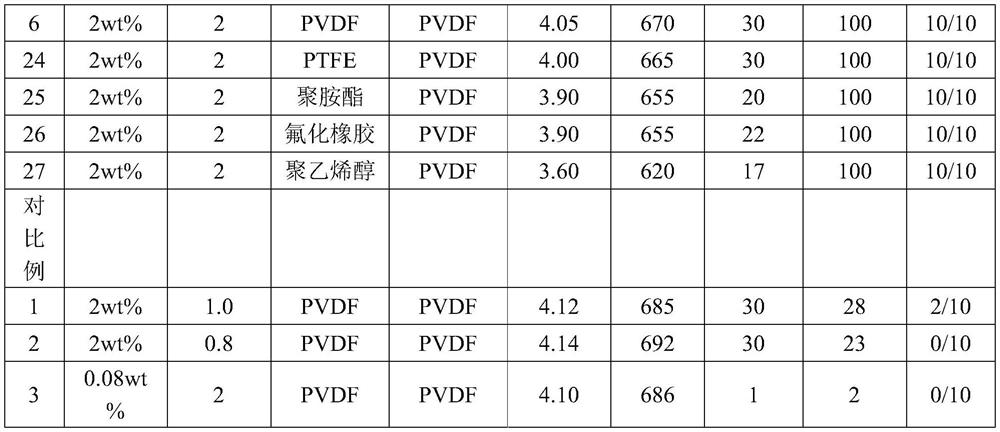

[0032] Preparation of positive electrode plate: (1) lithium cobalt oxide (LiCoO) 2 ), nickel cobalt manganese, nickel cobalt lithium aluminate, lithium iron phosphate (LiFePO 4 ), preferably lithium cobaltate (LiCoO 2 ), the conductive agent carbon black (Super P) is mixed with the binder polyvinylidene fluoride (the content of the binder can be adjusted within the range of 0.1-5wt%) according to the weight ratio of 90-98:1-2 , add N-methylpyrrolidone (NMP), stir under the action of a vacuum mixer until the system becomes a uniformly dispersed slurry, and obtain the upper cathode slurry; (2) such as lithium cobalt oxide (LiCoO 2 ), lithium nickel cobalt mangan...

Embodiment 1

[0040] (1) Preparation of positive electrode plate

[0041] The positive active material lithium cobaltate, the conductive agent Super P, and the binder polyvinylidene fluoride (PVDF) were mixed in a weight ratio of 97.6:2.3:0.1, and N-methylpyrrolidone (NMP) was added. Under the action of a vacuum mixer Stir until the system becomes a uniform slurry to obtain the upper layer positive electrode slurry;

[0042] The positive active material nickel cobalt lithium manganate, the conductive agent Super P, and the binder polyvinylidene fluoride (PVDF) were mixed in a weight ratio of 96.6:3.2:0.2, and N-methylpyrrolidone (NMP) was added. Under the action of stirring until the system becomes a uniform slurry, the lower layer positive electrode slurry is obtained;

[0043] First, the lower layer of positive electrode slurry is uniformly coated on the aluminum foil of the positive electrode current collector to prepare the first active material layer; the first active material layer i...

Embodiment 2

[0053] The preparation methods of the positive pole piece, the negative pole piece, the electrolyte, the separator and the lithium ion battery are the same as those in Example 1, the difference is that in the preparation process of the positive pole piece, the upper and lower layers of the positive electrode slurry are kept in the upper and lower layers. Under the condition that the content of the conductive agent SuperP is unchanged, the content of the binder polyvinylidene fluoride (PVDF) in the upper cathode slurry (corresponding to the second active material layer) is adjusted to 0.5 wt%, and the lower cathode slurry is adjusted. The content of the binder polyvinylidene fluoride (PVDF) (corresponding to the first active material layer) is such that the content of polyvinylidene fluoride (PVDF) in the lower cathode slurry is the same as the polyvinylidene fluoride (PVDF) in the upper cathode slurry. The content ratio of (PVDF) was 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com