HIPS (High Impact Polystyrene) resin production process system containing internal circulation device and high-performance HIPS resin preparation method

A production process and internal circulation technology, applied to the method of using atmospheric pressure to chemically change substances, chemical instruments and methods, chemical industry, etc., can solve the problem of wide molecular weight distribution of rubber particles, high energy consumption of reactors, and poor system stability and other problems, to achieve the effects of narrow molecular weight distribution of rubber particles, improved dispersion, and excellent processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

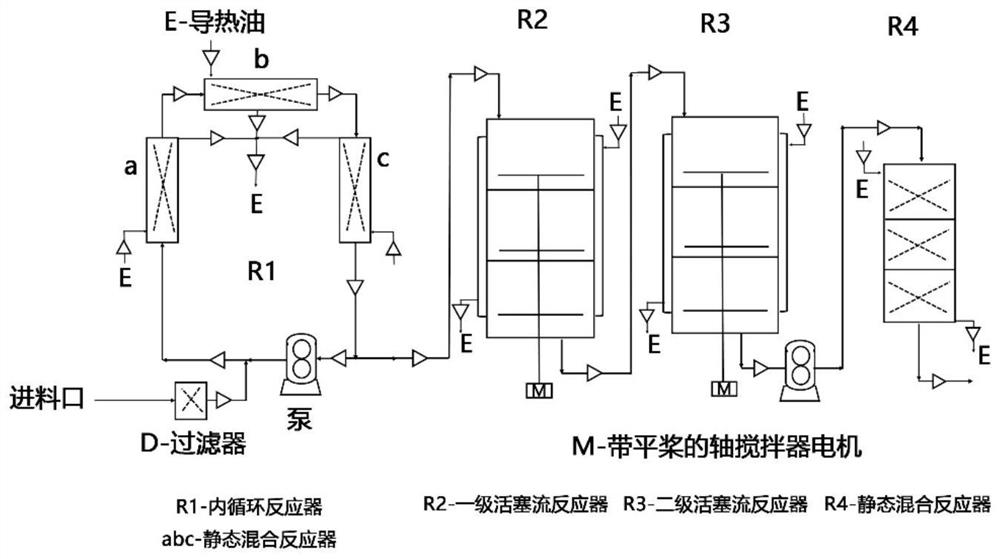

[0055] like figure 1 As shown, a HIPS resin production process system containing an internal circulation device comprises an internal circulation reactor R1, a first plug flow reactor R2, a second plug flow reactor R3 and a static mixing reactor R4 which are connected in series through pipelines in sequence; The material output end of the static mixing reactor R4 is sequentially connected in series with the devolatilizer and the granulator through pipelines (not shown). The function of the devolatilizer is to flash off the unreacted styrene monomer and solvent and recycle it for recycling, and the molten material is passed through a granulator to obtain the HIPS resin product.

[0056] The internal circulation reactor R1 is a series loop composed of a first-stage static mixer a, a second-stage static mixer b, a third-stage static mixer c, and a circulating pump that are connected in sequence through pipelines; The series filter D is then communicated with the circulating loop...

Embodiment 2

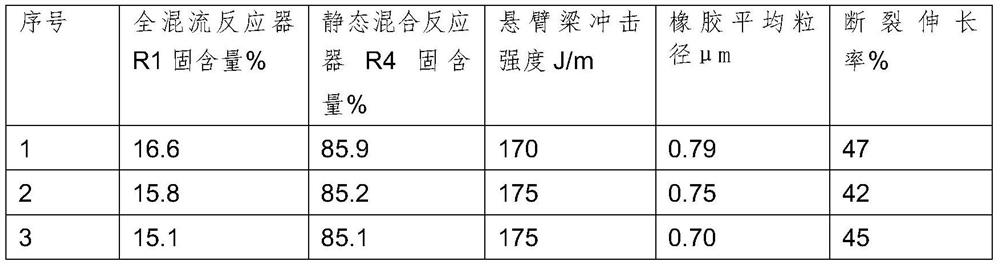

[0070] Use the high-performance HIPS resin produced in Example 1. The weight percentage of each component entering the fully mixed flow reactor R1 is: the mixed glue solution including the styrene, initiator, chain transfer agent and solvent of the dissolved polystyrene-butadiene-isoprene ternary integrated rubber accounts for The weight ratio is 8.4%, styrene accounts for 77.6% of the glue, and ethylbenzene accounts for 14% of the glue. The concentration of the initiator in the styrene solution was 70 ppm, and the flow rate was controlled at 0.7 g / h. The chain transfer agent accounts for 35ppm of styrene, and the control flow rate is 0.5g / h.

[0071] The setting temperature of the inner circulation reactor is 100-115°C, and the preferred temperatures of the first, second and third stage static mixers R1-abc in the inner circulation reactor are 105.1°C, 105.4°C, 105.8°C, and the pressure is 0.26°C. MPa, 0.27MPa, 0.28MPa, the plug flow reactor R2-3 is a tubular reactor, and t...

Embodiment 3

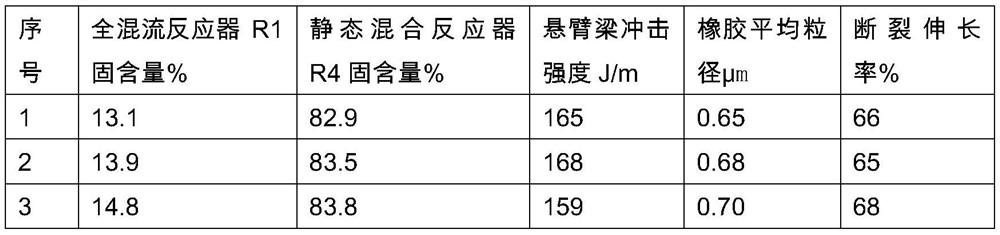

[0084] Use the high-performance HIPS resin produced in Example 1. The internal circulation reactor R1 is a prepolymerization reactor, and the continuous rubber phase undergoes a prepolymerization process of grafting GPPS in this reactor. The monomer is pumped back into the system to continue the reaction, which is beneficial to improve the rubber grafting rate and monomer conversion rate, and stabilize the product quality. The internal circulation R1 reactor helps to obtain rubber particles with narrow molecular weight molecules. The materials sequentially enter the primary and secondary plug flow reactors and the independently connected static mixing reactor R4 for further GPPS grafting reaction process. The weight percentage of each component in the raw material liquid entering the grafting reactor is: the amount of dissolved polystyrene-butadiene-isoprene ternary integrated rubber accounts for the mixture of styrene, initiator, chain transfer agent and solvent. The weight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com