Method for improving blood compatibility of resin by using PEG (Polyethylene Glycol) as spacer arm

A spacer arm, resin technology, applied in chemical instruments and methods, other chemical processes, ion exchange, etc., can solve problems such as gas embolism, inability to return blood, and unsatisfactory improvement in actual effects, to improve compatibility and increase swing. Sex, prevent the effect of not being able to return blood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

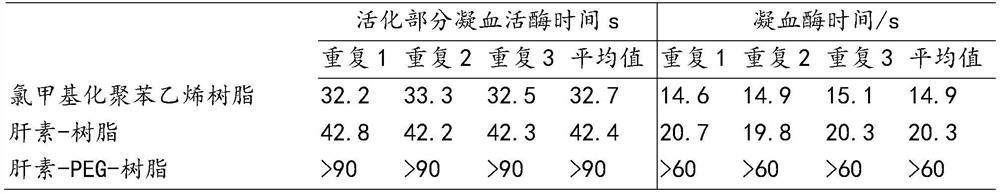

Examples

Embodiment 1

[0041] (1) Activation: take 6.0 g of chloromethylated polystyrene resin, rinse with 40 g / L NaOH solution for 4 hours, and then wash off the alkali solution with water to obtain an activated resin.

[0042] (2) put the resin treated in step (1) into the there-necked flask with condenser, soak 12h with 50mL toluene, fully swell, then add 36mmol PEG200, anhydrous potassium carbonate 5g, tetrabutylammonium bromide 0.5g, The reaction was stirred at 90° C. for 12 h. After the reaction was completed, rinsed with absolute ethanol for 5 times, rinsed with deionized water, and dried in vacuum to obtain PEG-resin (PEG loading amount was 0.156 g / g).

[0043] (3) Dissolve 50 mg of heparin sodium in 40 mL of water, stir evenly, and adjust to acidity with 2 mmol / L hydrochloric acid.

[0044] (4) Dissolve 40 g of dicyclohexylcarbodiimide (DDCI) in 10 mL of tetrahydrofuran, stir evenly, and pour it into the heparin sodium solution in step (3).

[0045] (5) Add the PEG-resin of step (2) to the...

Embodiment 2

[0059] The preparation of heparin-PEG-resin is the same as in Example 1, except that the PEG-resin is prepared by the following method:

[0060] (1) Take 10g of chloromethylated polystyrene resin and 3g of solid sodium hydroxide and put it in excess 120mL of PEG200.

[0061] (2) The first microwave irradiation was carried out according to the power of 600W, the temperature of 170°C, and the time of 15min.

[0062] (3) After the first microwave irradiation, cool to room temperature, repeat the microwave irradiation once, and filter with suction after cooling.

[0063] (4) Rinse with deionized water, 2mol / L hydrochloric acid, and methanol in turn, and cycle washing for 4-5 times.

[0064] (5) PEG-resin (PEG loading amount is 0.185g / g) is obtained after drying.

Embodiment 3

[0066] The difference from Example 1 is that PEG200 is replaced by PEG400.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Loading capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com