Ba3Zr2S7 film and preparation method and application thereof

A technology of ba3zr2s7 and thin films, which is applied in chemical instruments and methods, semiconductor/solid-state device manufacturing, zirconium compounds, etc., can solve the problems of poor stability of perovskite thin films, polluted environment, unsuitable bandgap width, etc., and achieve excellent stability, Excellent photoelectric performance, not easy to oxidize and decompose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

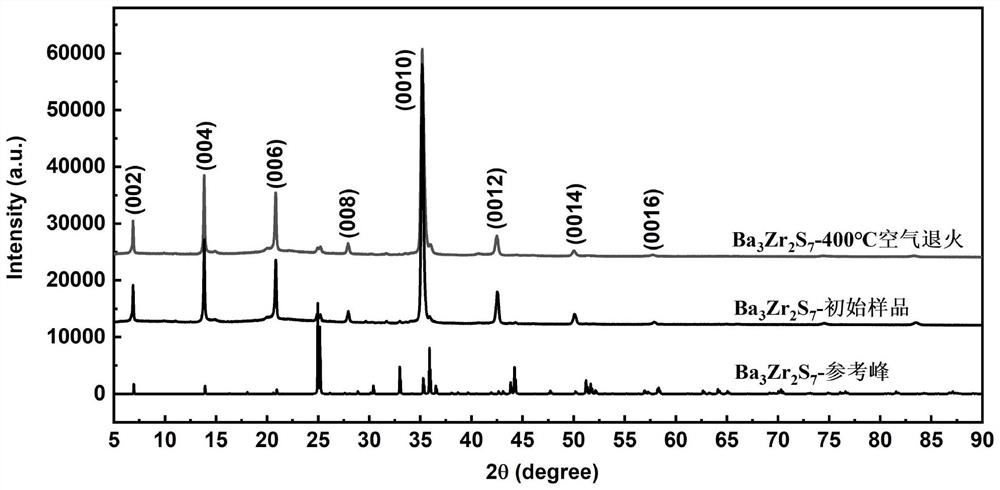

Embodiment 1

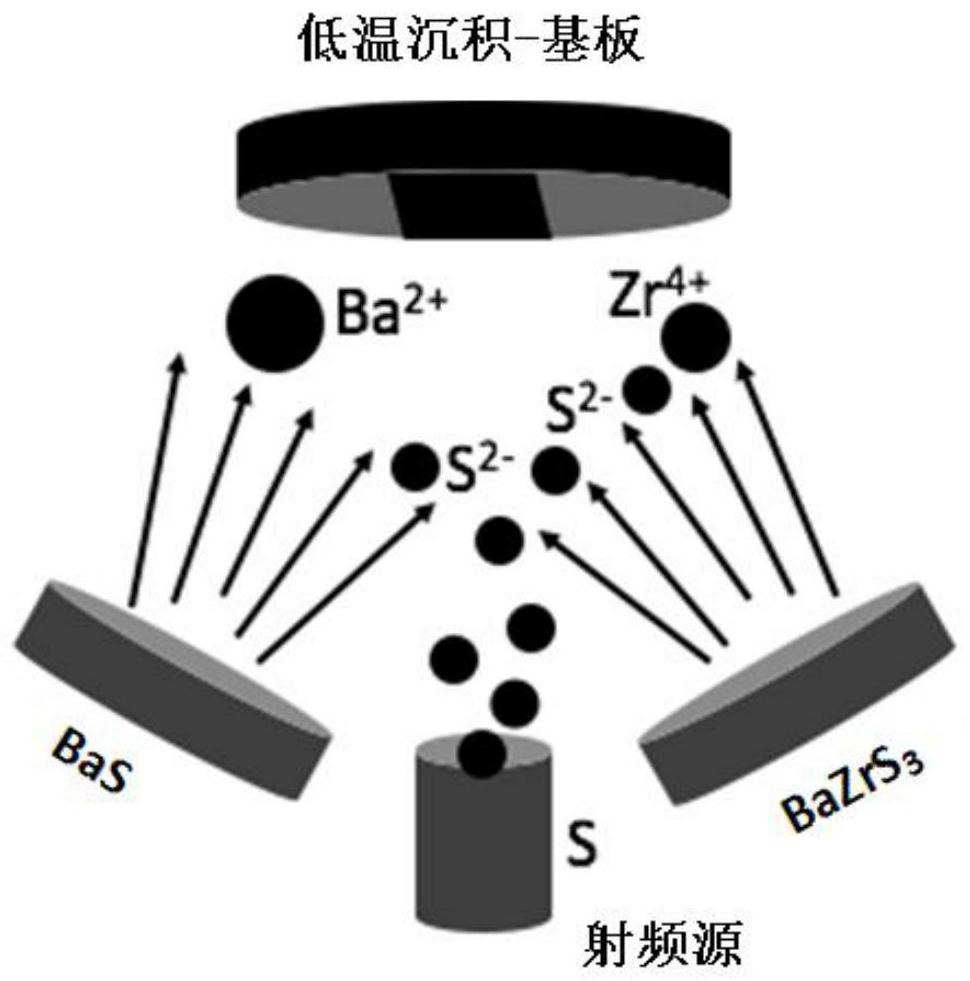

[0039] a Ba 3 Zr 2 S 7 The preparation method of the film includes the following steps:

[0040] (1) BaZrS 3 Preparation of target material:

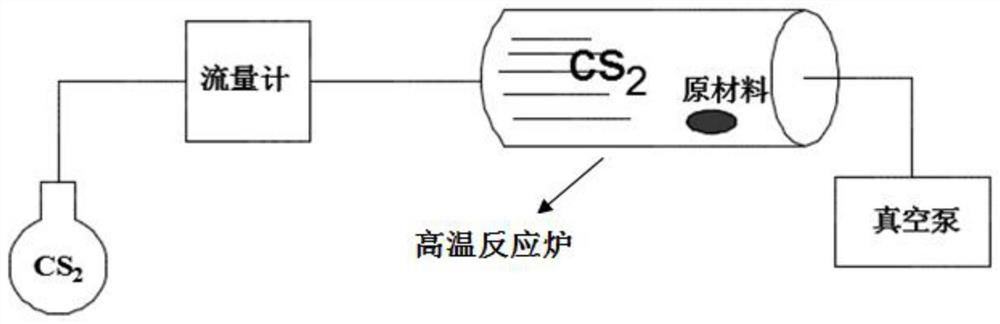

[0041] S1. Take BaCO 3 and ZrO 2 In order to react the raw material powder, it is prepared according to the substance ratio of 1:1, and it is subjected to vulcanization reaction to generate BaZrS 3 powder, and made into a target, the vulcanization reaction equation is 2BaCO 3 +2ZrO 2 +3CS 2 =2BaZrS 3 +10CO 2 , its high temperature vulcanization device such as figure 1 As shown, it includes a carbon disulfide supply device, a flow control device, a high temperature furnace, and a vacuum device, and the above devices are connected by a gas valve. The specific steps are as follows:

[0042] S11. Take BaCO 3 and ZrO 2 In order to react the raw material powder, put it into a high temperature reaction furnace, turn on the vacuum equipment, and pump the high temperature reaction furnace to the background vacuum, so that the vacu...

Embodiment 2

[0061] a Ba 3 Zr 2 S 7 The preparation method of the film includes the following steps:

[0062] (1) BaZrS 3 Preparation of target material:

[0063] S11. Weighing BaCO 3 and ZrO 2 The powder is prepared according to the substance ratio of 1:1. After fully grinding and mixing evenly, it is placed in a high-temperature reaction furnace, and the vacuum device is turned on for air extraction, and the high-temperature reaction furnace is pumped to the background vacuum to make the vacuum degree < 0.1Pa.

[0064] S12. Turn on the gas flow control device to make CS 2 The steam enters into the high temperature reaction furnace in step S11, and its flow rate is set to 30 SCCM.

[0065] S13. Set and execute a temperature program for the high-temperature reaction furnace in step S11, and control the vacuum pump to make the air pressure in the high-temperature reaction furnace 30Pa, gradually heat it up to 1000°C, and keep it for 1 hour, then cool to room temperature, and close t...

Embodiment 3

[0077] a Ba 3 Zr 2 S 7 The preparation method of the film includes the following steps:

[0078] (1) BaZrS 3 Preparation of target material:

[0079] S11. Weighing BaCO 3 and ZrO 2 The powder is prepared according to the substance ratio of 1:1. After fully grinding and mixing evenly, it is placed in a high-temperature reaction furnace, and the vacuum device is turned on for air extraction, and the high-temperature reaction furnace is pumped to the background vacuum to make the vacuum degree < 0.1Pa.

[0080] S12. Turn on the gas flow control device to make CS 2 The steam enters into the high temperature reaction furnace in step S11, and its flow rate is set to 30 SCCM.

[0081] S13. Set and execute a temperature program for the high-temperature reaction furnace in step S11, and control the vacuum pump to make the air pressure in the high-temperature reaction furnace 20Pa, gradually heat it up to 1050°C, and keep it for 1 hour, then cool to room temperature, and close t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com